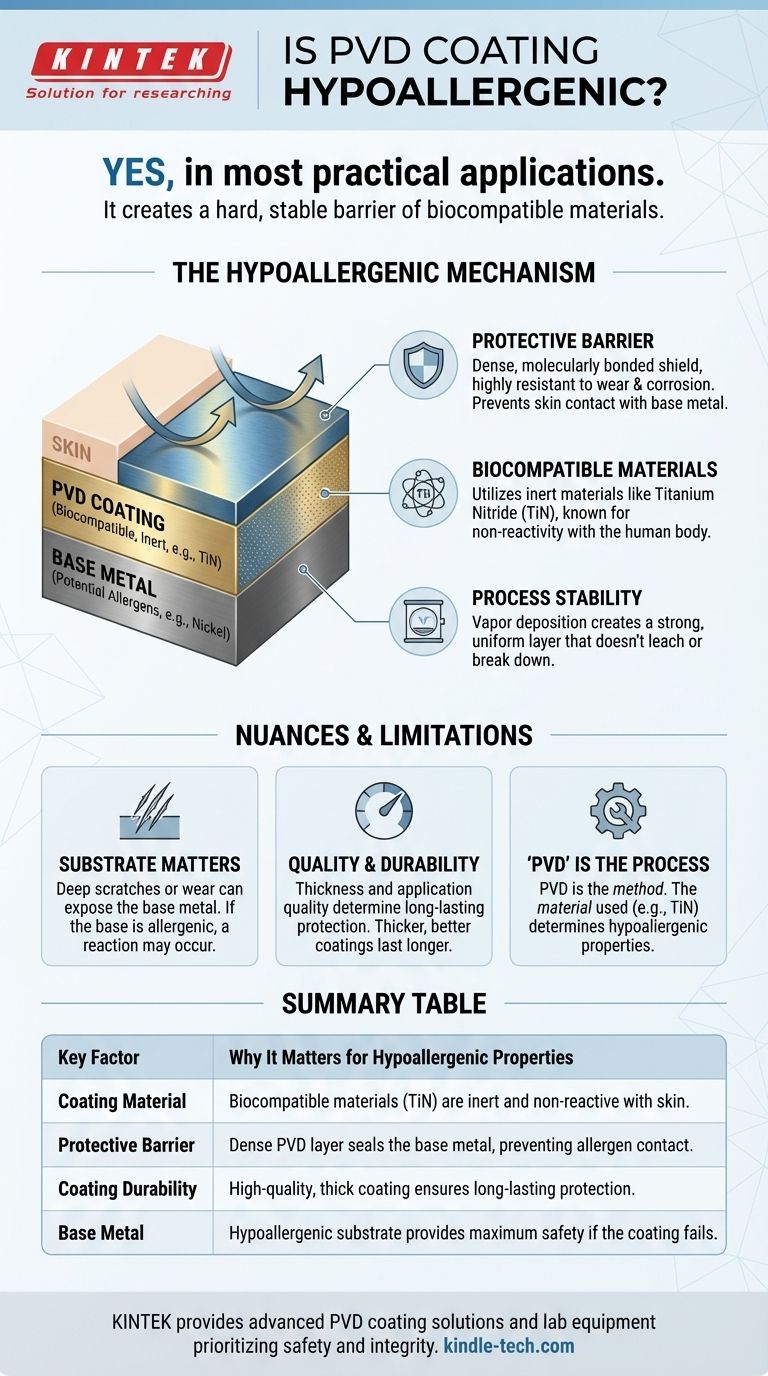

In most practical applications, yes. While the term PVD (Physical Vapor Deposition) refers to a process, not a specific material, the materials commonly used for consumer products like jewelry and watches are chosen for their inert and biocompatible properties. This process creates a hard, chemically stable layer that acts as an effective barrier between your skin and the base metal underneath.

The hypoallergenic nature of a PVD-coated item is not due to the process itself, but to the selection of biocompatible coating materials—like titanium or zirconium compounds—that effectively seal the potentially reactive base metal away from the skin.

What Makes a PVD Coating Hypoallergenic?

To understand why PVD coatings are trusted for skin-contact applications, we need to look at two key factors: the materials used and the nature of the barrier they create.

The Concept of a Protective Barrier

PVD creates a very thin, dense, and hard coating that is molecularly bonded to the surface of the object. This is not like a traditional paint or plating that can easily flake off.

This bonded layer is highly resistant to corrosion and wear. It acts as a durable shield, preventing the base metal (which may contain allergens like nickel) from ever coming into contact with your skin.

The Importance of Biocompatible Materials

The primary reason for the hypoallergenic property is the specific material being deposited. For decorative and durable finishes, manufacturers commonly use materials that are known to be biocompatible.

The most common of these is Titanium Nitride (TiN). Titanium is widely used in medical implants precisely because the human body does not react to it. When used as a PVD coating, it provides this same inert quality.

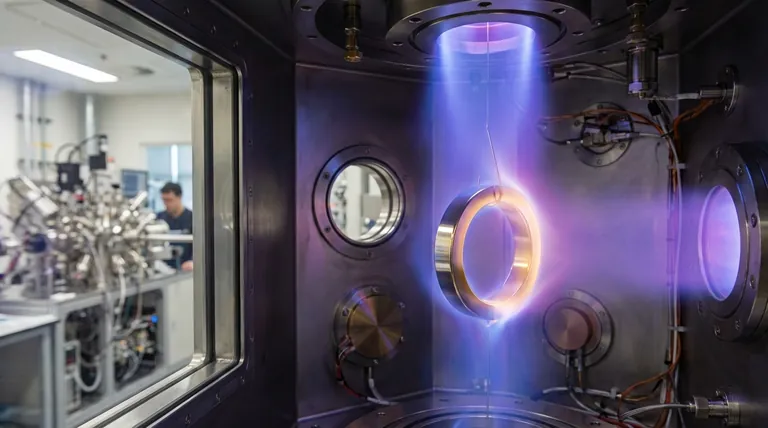

How the Process Ensures Stability

The PVD process involves turning a solid material into a vapor in a vacuum, which then condenses and bonds to the target object atom by atom.

This creates an extremely strong and uniform layer. Because the coating is so stable and well-adhered, it doesn't leach or break down, ensuring the protective barrier remains intact during normal use.

Understanding the Limitations and Nuances

While highly effective, it's crucial to approach the term "hypoallergenic" with a clear understanding of the complete system. The coating is only one part of the equation.

The Substrate Still Matters

The single most important consideration is that the PVD coating is a surface layer. If the coating is scratched deeply enough or eventually wears away after years of heavy use, the base metal will become exposed.

If this base metal is a material you are allergic to (like a steel alloy with a high nickel content), you could experience a reaction once the barrier is breached.

Coating Quality and Durability

Not all PVD applications are created equal. The durability of the hypoallergenic barrier depends on the thickness and quality of the coating.

A well-applied, sufficiently thick coating on a product from a reputable manufacturer will offer long-lasting protection. Conversely, an extremely thin or poorly adhered coating on a low-cost item may wear down more quickly.

"PVD" Describes the Process, Not the Material

Always remember that PVD is the how, not the what. A manufacturer could, in theory, use a reactive material in a PVD process. However, for consumer goods where skin contact is expected, the industry standard is to use safe, inert materials like titanium and zirconium compounds.

Making an Informed Choice for Your Goal

When selecting a PVD-coated product, your choice should be guided by your level of sensitivity and intended use.

- If your primary focus is maximum safety for highly sensitive skin: Look for products where both the PVD coating material (like titanium) and the base metal itself are hypoallergenic (e.g., surgical-grade stainless steel or pure titanium).

- If your primary focus is style and general durability: A PVD coating on standard stainless steel is an excellent and safe choice for the vast majority of people, as the coating provides a reliable barrier against potential allergens in the steel.

- If you are evaluating a product: Don't hesitate to ask the manufacturer what specific material is used for the PVD coating. A reputable brand will proudly state they use materials like Titanium Nitride.

Ultimately, PVD coating is a trusted technology that, when implemented with biocompatible materials, provides one of the safest and most durable finishes available today.

Summary Table:

| Key Factor | Why It Matters for Hypoallergenic Properties |

|---|---|

| Coating Material | Biocompatible materials like Titanium Nitride (TiN) are inert and non-reactive with skin. |

| Protective Barrier | The dense PVD layer seals the base metal, preventing contact with potential allergens. |

| Coating Durability | A high-quality, thick coating ensures long-lasting protection against wear and corrosion. |

| Base Metal | The substrate (e.g., stainless steel) should also be hypoallergenic for maximum safety. |

Ensure your laboratory equipment and consumables meet the highest standards of safety and durability. At KINTEK, we specialize in providing advanced PVD coating solutions and lab equipment that prioritize material integrity and user safety. Whether you need coatings for sensitive applications or reliable lab tools, our expertise ensures superior performance. Contact our specialists today to discuss how we can support your laboratory's specific needs with precision-engineered solutions.

Visual Guide

Related Products

- Custom CVD Diamond Coating for Lab Applications

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- 1200℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

People Also Ask

- Is diamond coating worth it? Maximize Component Life and Performance

- What are diamond coated films? Enhance Materials with Super-Hard, Transparent Layers

- What is diamond coating film? A Thin Layer of Diamond for Extreme Performance

- How are tools coated with diamond? Achieve Superior Hardness and Low Friction for Your Tools

- Is diamond coating permanent? The Truth About Its Long-Lasting Durability