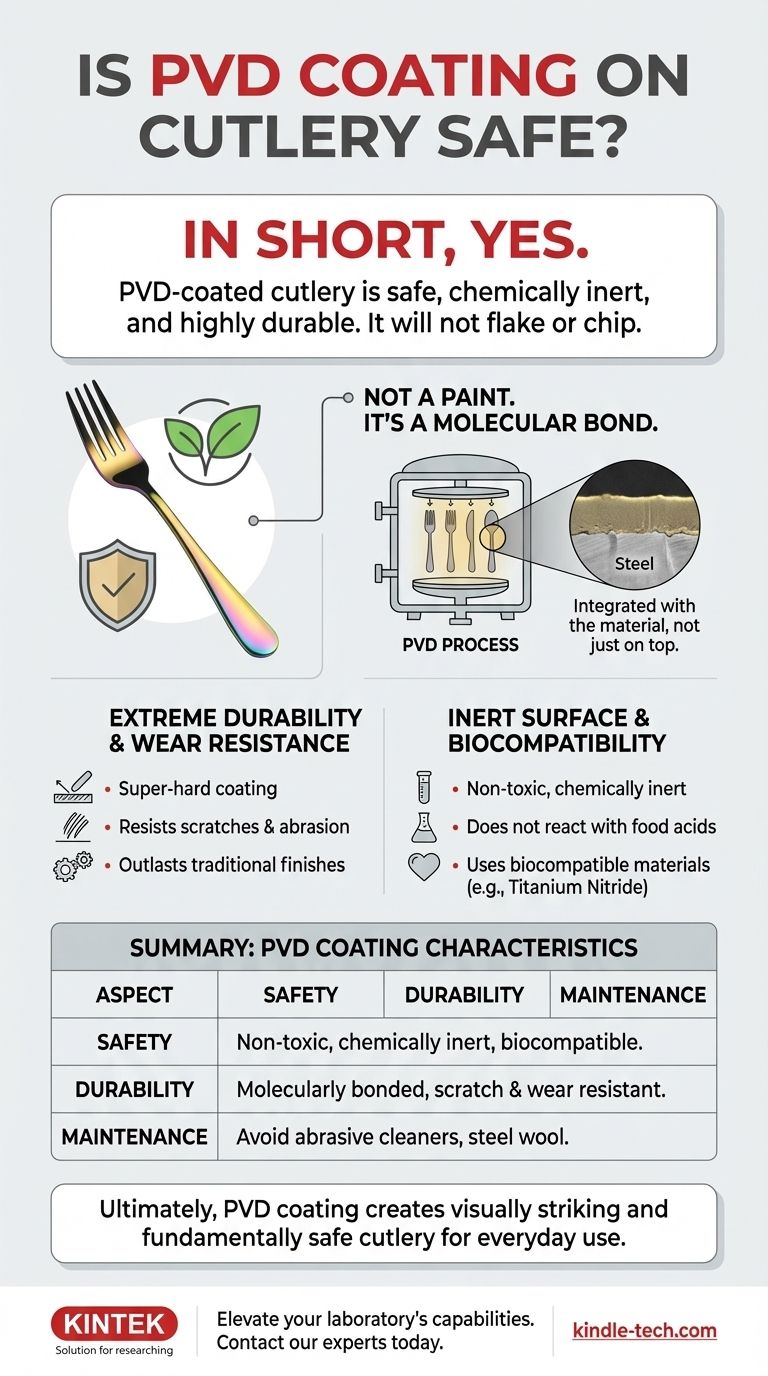

In short, yes. PVD-coated cutlery is considered safe for food contact. The process creates a finish that is chemically and biologically inert, meaning it will not react with or leach into your food. Because the coating is bonded to the stainless steel at a molecular level, it is highly durable and will not flake or chip off with normal use.

You see stylish black, gold, or iridescent flatware and wonder if the color is just a gimmick that will chip into your food. The key is understanding that PVD is not a paint or traditional plating; it is a high-tech vacuum deposition process that creates a durable, non-toxic surface that becomes part of the utensil itself.

What Exactly Is a PVD Coating?

Physical Vapor Deposition (PVD) is a modern finishing process conducted in a high-tech vacuum chamber. It is fundamentally different from older methods like painting or electroplating.

It's Not a Paint or Plating

Unlike a layer of paint that sits on top of a surface, a PVD coating is molecularly fused to the steel substrate. Think of it less like a coat of paint and more like a new, ultra-hard skin that is integrated with the original material.

The Process Creates an Inert Surface

The materials used for PVD cutlery coatings, such as titanium nitride, are chosen for their biocompatibility. These materials are non-toxic and do not react with acids or other compounds in your food. This is the same reason they are trusted for use in medical implants.

The Bond is Exceptionally Strong

The vacuum deposition process ensures the coating adheres with incredible strength. This prevents the chipping, flaking, or peeling you might associate with lower-quality coated kitchenware, ensuring particles do not mix with your food.

PVD's Core Advantage: Extreme Durability

While safety is the primary concern, the reason PVD is used so widely is its functional superiority. Its durability is what guarantees its safety over the long term.

Superior Wear Resistance

PVD is a super-hard coating that dramatically increases the utensil's resistance to scratches and abrasion from daily use. This is why it is used on commercial kitchen equipment that endures constant, heavy use.

A Finish That Lasts

A high-quality PVD finish will outlast virtually any traditional coating. It resists tarnishing and fading, keeping your cutlery looking new for far longer.

Understanding the Trade-offs and Considerations

While PVD is a superior technology, it's important to have realistic expectations.

Quality Varies by Manufacturer

The durability and safety of the finish depend entirely on the quality of the application. Reputable manufacturers use proper techniques and high-grade materials, while cheap, poorly executed PVD might not offer the same longevity.

Not Indestructible

While highly resistant, PVD coatings are not invincible. Using highly abrasive cleaners, steel wool, or aggressively scraping the utensils on ceramic can eventually scratch or wear down the finish.

Safety in Use vs. Application

The finished PVD product is completely safe for the consumer. The references to health risks from inhaling particles only apply to the manufacturing process, where workers must take proper precautions. This has no bearing on the safety of the final product in your home.

Making the Right Choice for Your Cutlery

To select the right PVD flatware, consider your main priority.

- If your primary focus is safety: PVD-coated cutlery from a reputable brand is an excellent choice, as the coating is non-toxic, inert, and strongly bonded to the steel.

- If your primary focus is durability: PVD offers superior resistance to scratches and wear compared to any traditional finish, making it a long-lasting investment.

- If your primary focus is aesthetics: The PVD process creates a stable and vibrant color, but proper care (like avoiding abrasive scrubbers) is still needed to maintain its pristine look.

Ultimately, PVD coating transforms standard cutlery into a product that is both visually striking and fundamentally safe for everyday use.

Summary Table:

| Aspect | PVD Coating Characteristic |

|---|---|

| Safety | Non-toxic, chemically inert, and biocompatible |

| Durability | Molecularly bonded to steel; highly resistant to scratches and wear |

| Composition | Not a paint; typically uses materials like titanium nitride |

| Maintenance | Avoid abrasive cleaners and steel wool to preserve the finish |

Elevate your laboratory's capabilities with the same precision used in high-tech coatings. KINTEK specializes in premium lab equipment and consumables, providing the reliable tools you need for research and quality control. Whether you're developing new materials or testing product safety, our solutions ensure accuracy and durability. Contact our experts today to find the perfect equipment for your lab's unique needs.

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- VHP Sterilization Equipment Hydrogen Peroxide H2O2 Space Sterilizer

- Molybdenum Tungsten Tantalum Special Shape Evaporation Boat

People Also Ask

- How are PECVD and CVD different? A Guide to Choosing the Right Thin-Film Deposition Process

- What are the advantages of PECVD? Enable Low-Temperature, High-Quality Thin-Film Deposition

- What are the applications of PECVD? Essential for Semiconductors, MEMS, and Solar Cells

- What is plasma activated chemical vapour deposition method? A Low-Temperature Solution for Advanced Coatings

- Why does PECVD commonly use RF power input? For Precise Low-Temperature Thin Film Deposition