From a consumer safety perspective, yes, PVD coating is entirely safe for use on cutlery. The process creates a molecular bond between the coating and the steel, resulting in an inert, non-toxic, and highly durable surface. This finished layer is biocompatible and will not leach into your food.

The critical distinction to understand is that the potential health risks associated with PVD materials exist only during the industrial application process, not with the finished product you use in your home. For the end-user, PVD-coated cutlery is exceptionally safe.

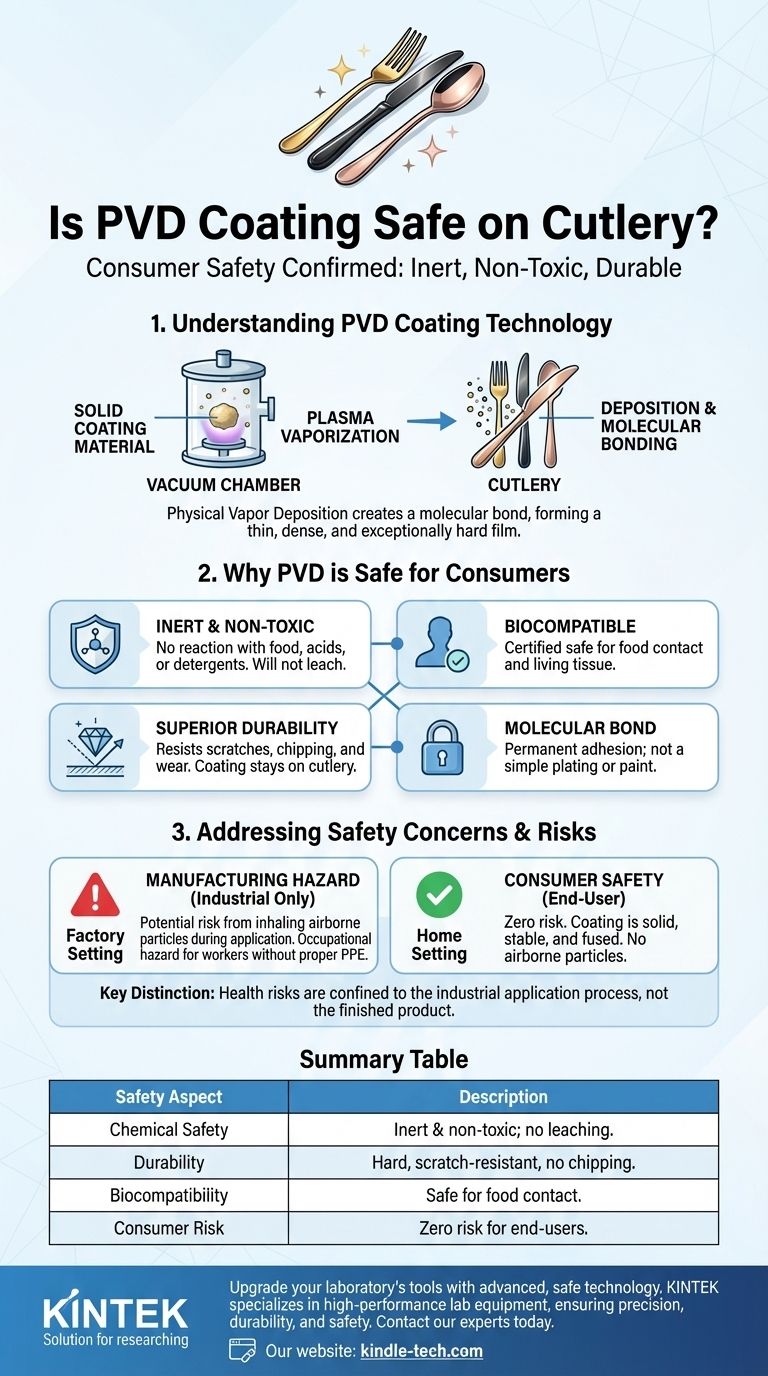

What is PVD Coating and Why is it Safe?

To understand the safety of PVD cutlery, it's important to understand the nature of the coating itself. PVD is not a paint or a simple plating; it's a high-tech process that fundamentally changes the surface of the steel.

The PVD Process in Brief

PVD stands for Physical Vapor Deposition. In a high-vacuum chamber, a solid coating material (often a ceramic like titanium nitride) is vaporized into a plasma. This vapor is then deposited onto the cutlery, forming a thin, dense, and exceptionally hard film that is molecularly bonded to the steel beneath it.

The Result: An Inert, Biocompatible Layer

The materials used for cutlery coatings are chosen for their inert properties. This means they do not react with acids, alkaline substances, or detergents. Because the coating is chemically stable, it is considered completely food-safe and biocompatible, meaning it is not harmful to living tissue.

Superior Durability Equals Lasting Safety

A key component of its safety is its incredible durability. A coating that doesn't chip, flake, or wear off cannot be accidentally ingested. PVD is a super-hard coating that provides superior resistance to scratches and daily wear, ensuring the protective layer stays exactly where it's supposed to: on the cutlery.

Understanding the Safety Nuances

While the final product is safe, the references to health risks can cause confusion. This concern is valid but applies to a completely different context.

The Real Hazard: The Manufacturing Process

The potential risk from PVD materials involves inhaling microscopic airborne particles. This is a potential occupational hazard for factory workers during the application process if proper ventilation and personal protective equipment are not used.

Once the coating is bonded to the cutlery in the vacuum chamber, the particles are no longer airborne. They are fused into a solid, stable layer, posing no risk to the consumer.

The Importance of Quality Control

The safety and durability of the final product depend on the quality of the manufacturing. Reputable manufacturers ensure the PVD process is executed correctly, resulting in a flawless, uniform bond. A poorly applied coating could theoretically fail, which is why choosing established brands is always recommended.

Making the Right Choice for Your Cutlery

Your decision should be based on what you value most for your daily use.

- If your primary focus is maximum safety and peace of mind: PVD-coated cutlery is an excellent choice, as the inert coating is molecularly bonded and will not leach into food.

- If your primary focus is long-term durability and appearance: PVD offers superior resistance to scratches, tarnishing, and wear, ensuring your cutlery looks new for far longer than traditional finishes.

- If your primary focus is a simple, traditional finish: Uncoated, high-quality stainless steel remains a perfectly safe and reliable option, though it lacks the enhanced scratch resistance of PVD.

Ultimately, PVD coating represents a safe, durable, and highly reliable finish for modern cutlery.

Summary Table:

| Safety Aspect | Description |

|---|---|

| Chemical Safety | Coating is inert and non-toxic; will not react with food or leach chemicals. |

| Durability | Molecular bond creates a hard, scratch-resistant surface that resists chipping and wear. |

| Biocompatibility | Certified safe for contact with food and living tissue. |

| Consumer Risk | Zero risk for end-users; any potential hazards are confined to the industrial manufacturing process. |

Upgrade your laboratory's tools with the same advanced, safe technology. KINTEK specializes in high-performance lab equipment and consumables, ensuring the precision, durability, and safety your research demands. Contact our experts today to find the perfect solutions for your laboratory's needs.

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- VHP Sterilization Equipment Hydrogen Peroxide H2O2 Space Sterilizer

People Also Ask

- Why does PECVD commonly use RF power input? For Precise Low-Temperature Thin Film Deposition

- How are PECVD and CVD different? A Guide to Choosing the Right Thin-Film Deposition Process

- What are the benefits of PECVD? Achieve Superior Low-Temperature Thin Film Deposition

- What is an example of PECVD? RF-PECVD for High-Quality Thin Film Deposition

- What is plasma activated chemical vapour deposition method? A Low-Temperature Solution for Advanced Coatings