Yes, pyrolysis oil is classified as a biofuel. It is a liquid fuel derived directly from the thermal decomposition of biomass, which is organic material from plants or animals. However, it's more accurately described as a "bio-crude" or "bio-oil" because its chemical properties differ significantly from both conventional fossil fuels and other processed biofuels.

While pyrolysis oil is a biofuel because it originates from biomass, it is not a "drop-in" replacement for conventional fuels. Its unique characteristics, such as high density and oxygen content, mean it often requires specialized equipment or further refining to be used effectively.

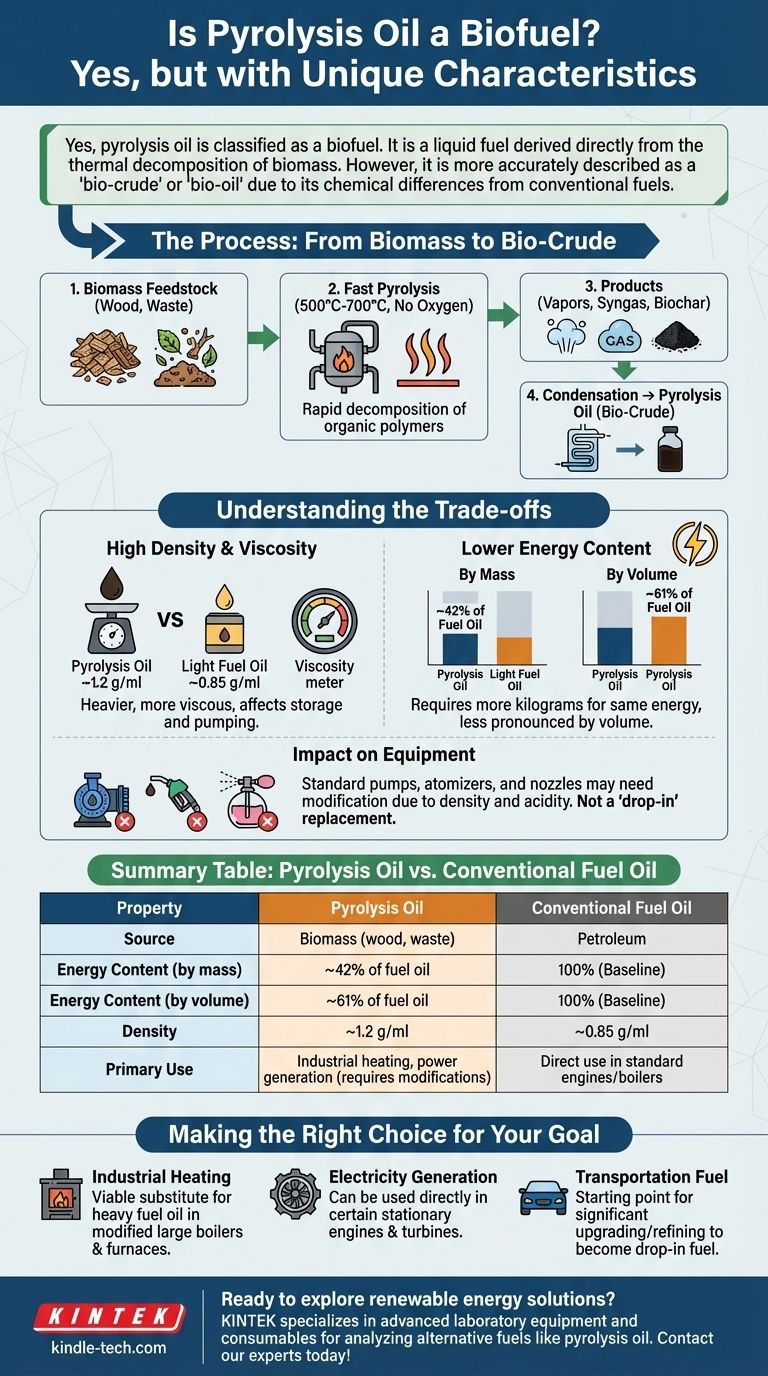

The Process: From Biomass to Bio-Crude

The creation of pyrolysis oil is a distinct thermochemical process that fundamentally re-arranges organic matter into a liquid energy carrier.

High-Temperature, Oxygen-Free Reaction

The core of the process is fast pyrolysis. Biomass feedstock (like wood chips, agricultural waste, or manure) is heated rapidly to high temperatures, typically between 500°C and 700°C.

Crucially, this occurs in an environment with no oxygen. Instead of burning, the heat breaks down the complex organic polymers of the biomass.

Vapor, Gas, and Char

This rapid decomposition creates three primary products: pyrolysis vapors, non-condensable syngas, and a solid carbon-rich material called biochar.

Condensing the Bio-Crude

After the solid biochar is separated, the hot pyrolysis vapors are rapidly cooled and condensed. This condensed liquid is the final product: pyrolysis oil, a dark, thick liquid often referred to as bio-crude.

Understanding the Trade-offs of Pyrolysis Oil

Viewing pyrolysis oil as a direct equivalent to diesel or heating oil is a common mistake. Its properties demand specific engineering considerations.

High Density and Viscosity

Pyrolysis oil is significantly denser than conventional fuels. Its density is around 1.2 g/ml, compared to light fuel oil at approximately 0.85 g/ml. This means it is heavier and often more viscous, affecting storage and pumping requirements.

Lower Energy Content by Weight

On a weight-for-weight basis, pyrolysis oil contains significantly less energy than petroleum-based fuel oil. It has roughly 42% of the energy content of fuel oil by mass. You simply need more kilograms of pyrolysis oil to produce the same amount of heat.

A Different Story by Volume

Because of its high density, the energy difference is less pronounced when measured by volume. Pyrolysis oil has about 61% of the energy content of fuel oil by volume. This is a critical factor for designing fuel tanks and delivery systems.

Impact on Equipment

The unique properties of pyrolysis oil directly impact equipment design. Standard pumps, atomizers, and nozzles designed for lighter, less dense fossil fuels may not function correctly or efficiently without modification. Furthermore, its acidic nature and high water content can make it corrosive to standard materials over time.

Making the Right Choice for Your Goal

Whether pyrolysis oil is a suitable fuel depends entirely on the intended application and the willingness to adapt to its unique characteristics.

- If your primary focus is industrial heating: Pyrolysis oil can be a viable substitute for heavy fuel oil in large boilers, furnaces, and kilns, provided the system is designed or modified to handle its high viscosity and different combustion properties.

- If your primary focus is electricity generation: It can be used directly in certain stationary engines and turbines designed for heavy or crude oils, offering a pathway for renewable power generation.

- If your primary focus is creating transportation fuel: Consider pyrolysis oil a starting point. It must undergo significant upgrading and refining (a process called hydrotreating) to remove oxygen and improve its stability, turning it into a "drop-in" fuel like renewable diesel or gasoline.

Ultimately, treating pyrolysis oil as the unique bio-crude that it is, rather than a simple fuel substitute, is the key to leveraging its potential.

Summary Table:

| Property | Pyrolysis Oil | Conventional Fuel Oil |

|---|---|---|

| Source | Biomass (wood, waste) | Petroleum |

| Energy Content (by mass) | ~42% of fuel oil | 100% (Baseline) |

| Energy Content (by volume) | ~61% of fuel oil | 100% (Baseline) |

| Density | ~1.2 g/ml | ~0.85 g/ml |

| Primary Use | Industrial heating, power generation (may require equipment modifications) | Direct use in standard engines/boilers |

Ready to explore renewable energy solutions for your lab or facility?

KINTEK specializes in advanced laboratory equipment and consumables, including systems for analyzing alternative fuels like pyrolysis oil. Whether you're researching biofuel properties, optimizing processes, or need reliable lab gear, we provide the tools and expertise to support your innovation.

Contact our experts today to discuss how we can help you achieve your energy and sustainability goals.

Visual Guide

Related Products

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Heating Pyrolysis Plant

- Customizable CO2 Reduction Flow Cell for NRR ORR and CO2RR Research

- Customizable PEM Electrolysis Cells for Diverse Research Applications

- Quartz Electrolytic Electrochemical Cell for Electrochemical Experiments

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

People Also Ask

- How are composites processed using sintering? Engineered Material Solutions Through Advanced Thermal Bonding

- How is the operational mode of bed motion selected for a rotary kiln? Optimize Heat Transfer and Material Homogeneity

- What are the zones in rotary kiln in cement production? Master the Core Process for High-Quality Clinker

- What is the drying zone in a rotary kiln? Boost Efficiency with Modern Drying Solutions

- How does precision temperature control impact TiAl alloy sintering? Master Microstructure Development