In short, yes, pyrolysis oil is harmful. It is a complex and reactive substance that poses significant risks to human health, is corrosive to equipment, and is chemically unstable. Its hazardous properties are a direct result of the process that creates it, which "freezes" reactive intermediate compounds from biomass decomposition into a liquid mixture.

The key takeaway is to view pyrolysis oil not as a finished, ready-to-use fuel, but as a raw, hazardous intermediate. Its harmfulness stems from its unrefined nature, requiring specialized handling, equipment, and often further processing to be used safely and effectively.

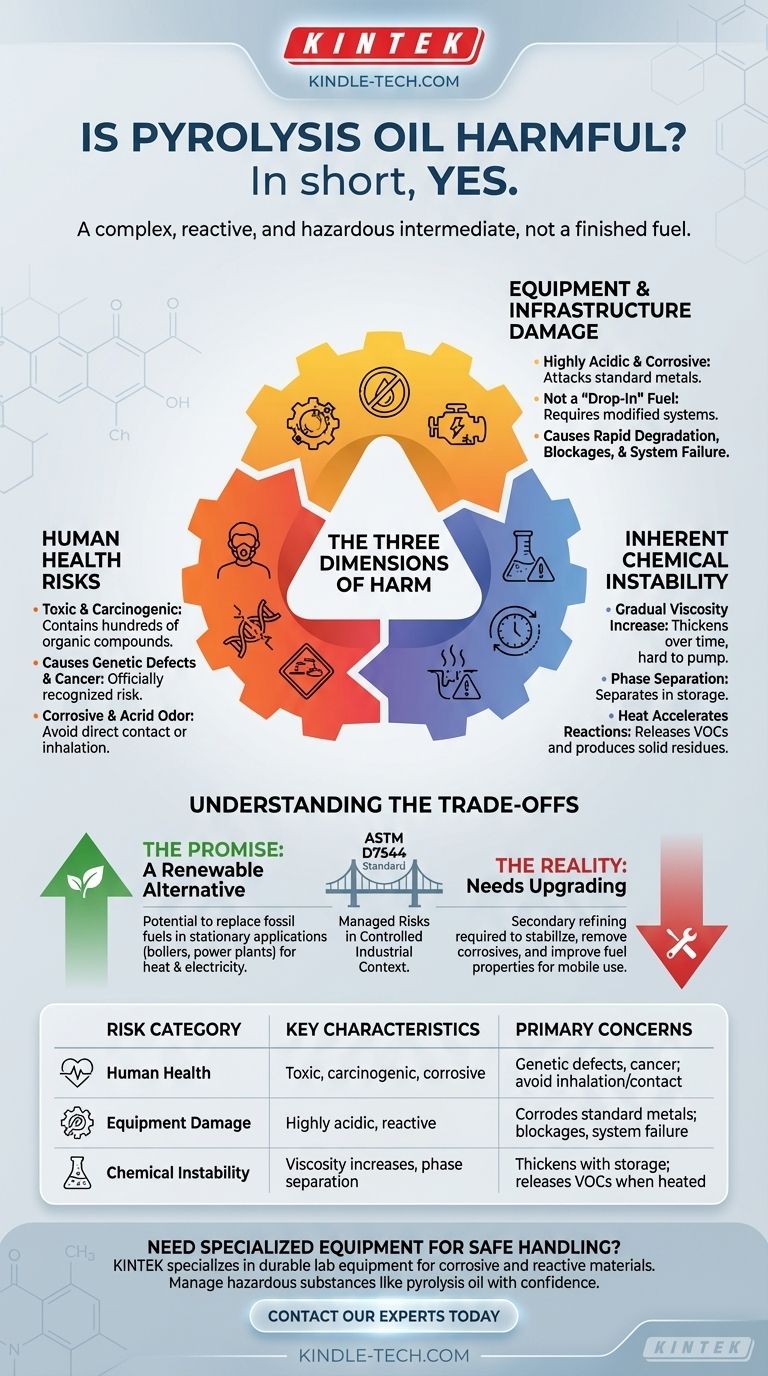

The Three Dimensions of Harm

To properly assess the risk, you must understand that the "harm" associated with pyrolysis oil is multi-faceted, impacting health, equipment, and operational stability.

Risks to Human Health

Pyrolysis oil is hazardous upon exposure. Its chemical makeup, a complex emulsion of hundreds of organic compounds, includes substances that are toxic and carcinogenic.

Direct contact or inhalation should be avoided. The oil is officially recognized as being able to cause genetic defects and cancer. It is also corrosive and has a distinct, acrid odor, signaling its reactive nature.

Damage to Equipment and Infrastructure

One of the most significant practical challenges of pyrolysis oil is its effect on machinery. It is highly acidic and corrosive to most standard metals used in fuel tanks, lines, and engines.

This corrosiveness limits its use as a simple "drop-in" fuel. Using it in conventional systems without modifications can lead to rapid degradation of components, fuel blockages, and system failure.

Inherent Chemical Instability

Pyrolysis oil is not a stable product like petroleum diesel. It is a collection of reactive molecules that continue to change over time, even in storage.

This instability manifests as a gradual increase in viscosity, making it thicker and harder to pump. Over time, it can also undergo phase separation. Applying heat can accelerate these reactions, producing solid residues and releasing volatile organic compounds (VOCs).

Understanding the Trade-offs: A Raw Feedstock, Not a Finished Fuel

The harmful properties of pyrolysis oil do not eliminate its potential value, but they do define how it must be handled and used. It is a classic trade-off between a renewable resource and the technical challenges it presents.

The Promise: A Renewable Alternative

The primary driver for interest in pyrolysis oil is its potential to replace conventional fossil fuels. It can be burned in stationary applications like industrial boilers and large power plants to generate heat and electricity.

The Reality: The Need for Upgrading

For most applications, especially mobile engines or integration into existing refineries, pyrolysis oil must be "upgraded." This is a secondary refining process that stabilizes the oil, removes corrosive elements, and improves its fuel properties.

Without upgrading, its use is confined to specialized systems designed to tolerate its challenging characteristics.

The Role of Standards

To manage its risks in specific applications, standards have been developed. For example, ASTM D7544 provides specifications for using pyrolysis oil in stationary burners, ensuring that equipment is compatible and safety measures are in place.

This demonstrates that the harms can be managed within a controlled industrial context, but it is not a consumer-grade product.

Making the Right Choice for Your Goal

Your approach to pyrolysis oil must be dictated by your specific objective.

- If your primary focus is direct fuel replacement: You must use equipment specifically designed for corrosive and viscous fuels or limit your application to stationary power generation under strict operational standards.

- If your primary focus is environmental sustainability: Acknowledge that while the oil is derived from biomass, its handling requires rigorous safety protocols and its combustion must be managed to control emissions of potentially harmful byproducts.

- If your primary focus is refining or chemical production: Treat pyrolysis oil as a hazardous raw material that requires significant processing to be converted into a stable, safe, and valuable final product.

Ultimately, managing the risks of pyrolysis oil requires understanding its true chemical nature as a reactive and unrefined intermediate.

Summary Table:

| Risk Category | Key Characteristics | Primary Concerns |

|---|---|---|

| Human Health | Toxic, carcinogenic, corrosive | Can cause genetic defects, cancer; avoid inhalation/contact |

| Equipment Damage | Highly acidic, reactive | Corrodes standard metals; causes blockages and system failure |

| Chemical Instability | Viscosity increases over time; phase separation | Thickens with storage; releases VOCs when heated |

Need specialized equipment to handle pyrolysis oil safely? KINTEK specializes in durable lab equipment and consumables designed for corrosive and reactive materials. Our solutions help laboratories manage hazardous substances like pyrolysis oil with confidence. Contact our experts today to find the right tools for your lab's safety and efficiency.

Visual Guide

Related Products

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Heating Pyrolysis Plant

- Cylindrical Lab Electric Heating Press Mold for Laboratory Applications

- Ball Press Mold for Lab

- Oil Free Diaphragm Vacuum Pump for Laboratory and Industrial Use

- Special Heat Press Mold for Lab Use

People Also Ask

- What is bio-oil carbon removal? A Permanent Solution for Capturing CO2 from Biomass Waste

- What makes Ultra-Low Temperature freezers energy efficient? Key Design & Operational Strategies

- What is the purpose of an ice water bath in microwave pyrolysis? Enhance Bio-Oil Yield and Sample Integrity

- What are the three steps in the sintering cycle? Master the Process for Stronger Parts

- What is the vacuum sublimation method? A Guide to High-Purity Material Purification

- What is the effect of sintering temperature on density? Mastering the Balance for Optimal Material Properties

- What are the waste products of biomass? Uncover Byproducts from Ash to Biochar

- What is pyrolysis oil used for? Unlocking Renewable Energy from Waste