Yes, fused quartz is exceptionally resistant to chemicals. It is renowned in scientific and industrial fields for its high degree of chemical purity and inertness, making it a benchmark material for applications where contamination or corrosion is a critical concern.

Fused quartz's value comes from a powerful combination of properties. Its high chemical resistance is not an isolated feature but is fundamentally linked to its purity, thermal stability, and structural integrity, making it a superior choice for the most demanding environments.

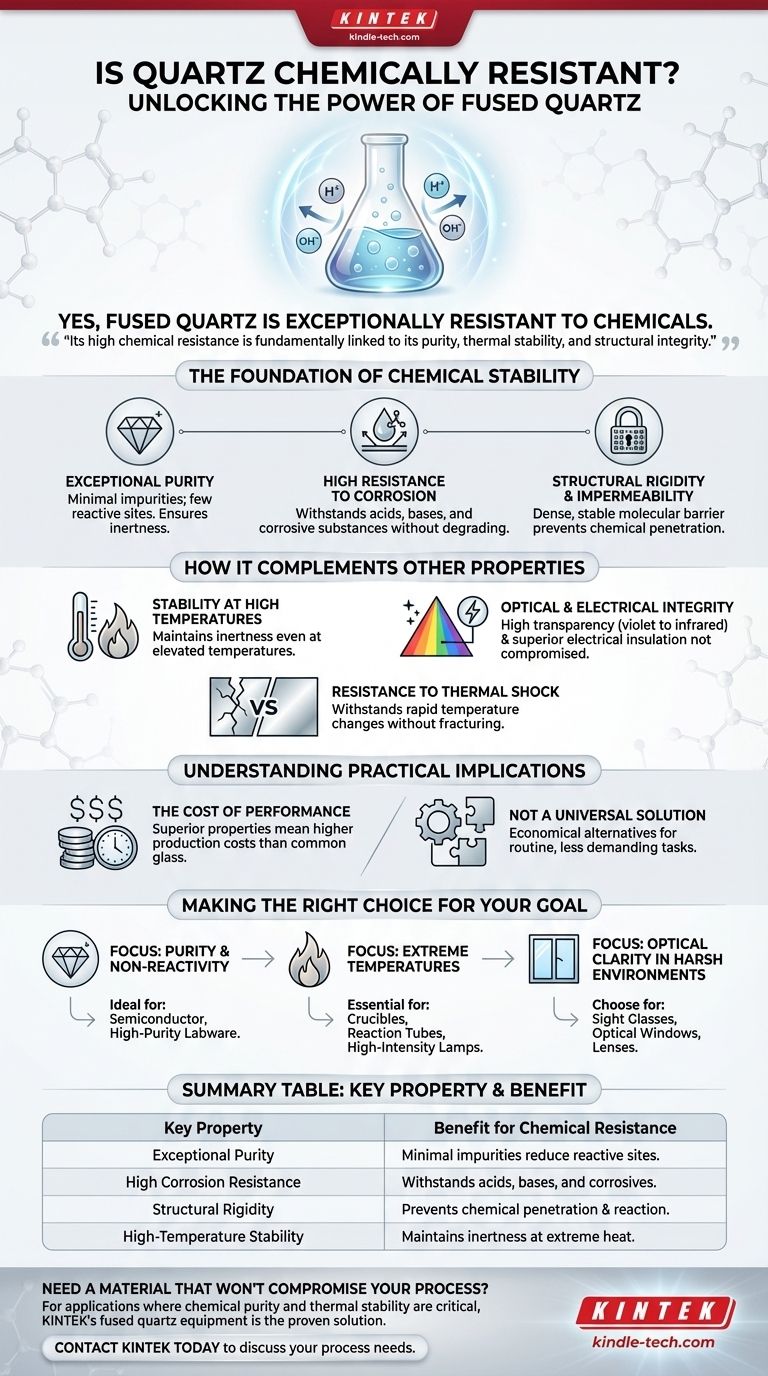

The Foundation of Quartz's Chemical Stability

The chemical resistance of fused quartz is not accidental; it is a direct result of its fundamental material properties. Several key characteristics work together to create this highly stable material.

Exceptional Purity

Fused quartz possesses a high degree of chemical purity. This means there are very few impurities within the material that could act as reactive sites for chemicals to attack, ensuring it remains inert.

High Resistance to Corrosion

The material exhibits an inherently high resistance to corrosion. It can withstand exposure to a wide range of acids, bases, and other corrosive substances without degrading, which is critical for laboratory equipment and industrial components.

Structural Rigidity and Impermeability

Fused quartz is characterized by its extreme rigidity and impermeability to gases. Its dense, stable molecular structure forms a powerful physical barrier that prevents chemicals from penetrating or reacting with the material.

How Chemical Resistance Complements Other Properties

The true strength of fused quartz lies in how its chemical resistance is maintained across a wide range of operating conditions, supported by its other elite properties.

Stability at High Temperatures

Unlike many materials that become more reactive as temperature increases, fused quartz maintains its chemical inertness even at elevated temperatures. This is due to its high softening temperature and excellent thermal resistance.

Optical and Electrical Integrity

For applications in optics or electronics, chemical exposure can degrade performance. The stability of quartz ensures its high transparency, from violet to infrared, and its superior electrical insulation properties are not compromised in chemically active environments.

Resistance to Thermal Shock

Its extremely low thermal expansion means it can withstand rapid temperature changes without fracturing. This allows it to be used in processes involving both aggressive chemicals and intense thermal cycling.

Understanding the Practical Implications

While the properties of fused quartz are impressive, it's crucial to understand the context in which it is used. Its high-performance nature comes with practical considerations.

The Cost of Performance

Materials with such a superior and extensive list of properties, from chemical resistance to optical transparency, are typically more costly to produce and fabricate than common alternatives like borosilicate glass.

Not a Universal Solution

The exceptional characteristics of fused quartz may be unnecessary for less demanding applications. For routine tasks without extreme temperatures or highly corrosive agents, other materials may offer a more economical solution. Its specification is a deliberate choice for applications where lesser materials would fail.

Making the Right Choice for Your Goal

Selecting fused quartz should be based on the specific demands of your application.

- If your primary focus is purity and non-reactivity: Fused quartz is the ideal choice for semiconductor manufacturing, high-purity labware, and any process where sample contamination is unacceptable.

- If your primary focus is performance at extreme temperatures: Its ability to withstand both high heat and aggressive chemicals makes it essential for crucibles, reaction tubes, and high-intensity lamp envelopes.

- If your primary focus is optical clarity in a harsh environment: Choose fused quartz for sight glasses, optical windows, and lenses that will be exposed to corrosive chemicals or high radiation.

Ultimately, selecting fused quartz is a decision for applications where performance, purity, and reliability cannot be compromised.

Summary Table:

| Key Property | Benefit for Chemical Resistance |

|---|---|

| Exceptional Purity | Minimal impurities reduce reactive sites, ensuring inertness. |

| High Corrosion Resistance | Withstands a wide range of acids, bases, and other corrosive substances. |

| Structural Rigidity | Dense, stable structure prevents chemical penetration and reaction. |

| High-Temperature Stability | Maintains inertness even at extreme temperatures, unlike many materials. |

Need a material that won't compromise your process? For applications where chemical purity, thermal stability, and non-reactivity are critical, KINTEK's fused quartz equipment is the proven solution. From high-purity labware and semiconductor components to optical windows and high-temperature reactors, our products are engineered for performance in the most demanding environments.

Contact KINTEK today to discuss how our quartz solutions can protect your process and ensure your results.

Visual Guide

Related Products

- High Temperature Resistant Optical Quartz Glass Sheet

- Optical Window Glass Substrate Wafer Single Double Sided Coated K9 Quartz Sheet

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Laboratory Sterilizer Lab Autoclave Herbal Powder Sterilization Machine for Plant

People Also Ask

- What is the temperature range of quartz glass? Master Its Thermal Limits for Demanding Applications

- What is the working temperature of quartz glass? Master Its High-Temp Limits & Applications

- What are the uses of quartz glass? Essential for Extreme-Temperature and UV Applications

- What is optical quartz? The Ultimate Material for UV and High-Temp Optics

- What temperature does quartz glass melt at? Understanding Its Softening Point and Practical Limits