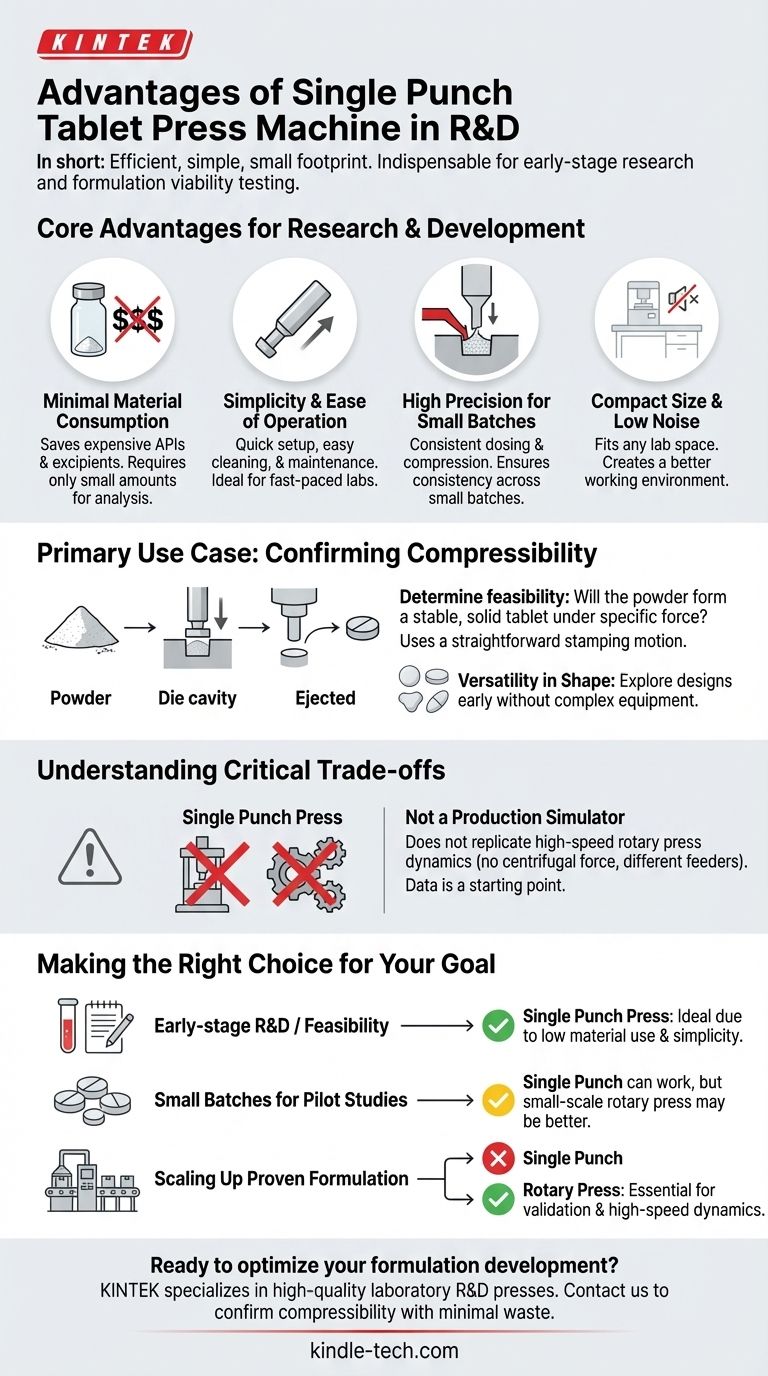

In short, the primary advantages of a single punch tablet press are its efficiency with minimal material, simplicity of operation, and small footprint. These characteristics make it an indispensable tool for early-stage research and development, where the goal is to test a formulation's viability without committing large amounts of expensive ingredients.

A single punch tablet press is not a miniature version of a large-scale rotary press. Its true value lies in its role as a precise, material-efficient tool for initial formulation development and confirming the fundamental compressibility of a powder.

The Core Advantages for Research & Development

A single punch press, also known as an eccentric press, is fundamentally designed for the laboratory environment. Its advantages align perfectly with the needs of formulation scientists and small-scale production.

Minimal Material Consumption

In the early phases of drug development, active pharmaceutical ingredients (APIs) and specialized excipients are often scarce and extremely expensive. The single punch press excels by requiring only a small amount of material to produce viable tablets for analysis.

Simplicity and Ease of Operation

This machine uses a single tooling station—one upper punch, one lower punch, and one die. This simple mechanical design makes it easy to set up, operate, clean, and maintain, which is a significant benefit in a fast-paced R&D setting.

High Precision for Small Batches

Despite its simplicity, a quality single punch press offers high precision in die filling. A component called a dosing plow pushes a precise, repeatable amount of powder into the die cavity before each compression, ensuring consistency across a small batch.

Compact Size and Low Noise

The machine’s small physical footprint allows it to fit easily into any lab space. Furthermore, its low-noise operation makes for a much better working environment compared to the loud, industrial-scale machinery used for mass production.

The Primary Use Case: Confirming Compressibility

Beyond its general features, the machine's most critical function is to answer a single, fundamental question: can this powder formulation be made into a tablet?

A Tool for Feasibility

Before investing in scaling up, you must confirm the compressibility of your powder blend. The single punch press is the perfect tool for this feasibility study, allowing you to determine if the mixture will form a stable, solid tablet under a specific compression force.

The Stamping Process

The machine operates using a straightforward stamping or hammer-like motion. The upper punch descends to exert a controlled force on the powder in the die cavity, after which the finished tablet is ejected. This simple process provides clear data on the formulation's basic properties.

Versatility in Shape

These presses can be fitted with different tooling to produce a variety of tablet shapes, both round and irregular. This allows for early exploration of tablet design without the need for complex, expensive equipment.

Understanding the Critical Trade-offs

To use a single punch press effectively, it is crucial to understand its limitations. Its greatest strength—simplicity—is also the source of its primary trade-off.

Not a Production Simulator

This machine does not replicate the key physical principles that govern high-speed, production-sized rotary presses. The data it provides is a starting point, not a final predictor of large-scale manufacturing success.

The Absence of Centrifugal Force

Large rotary presses use centrifugal force to assist in feeding powder into the dies at high speed. A single punch press lacks this dynamic entirely, meaning the powder flow characteristics can be very different.

Different Feeder Mechanics

The simple dosing plow on a single punch press behaves differently than the complex mechanical feeders on a production machine. Issues with powder flow, density, or particle size that are not apparent on a lab-scale press may become significant problems at high production speeds.

Making the Right Choice for Your Goal

Selecting the correct equipment depends entirely on your objective. The single punch press is a specialized tool, not a one-size-fits-all solution.

- If your primary focus is early-stage R&D or feasibility testing: The single punch press is the ideal choice due to its low material consumption and operational simplicity.

- If your primary focus is creating small batches for pilot studies: A single punch press can work, but a small-scale rotary press may provide more scalable and relevant data.

- If your primary focus is scaling up a proven formulation: Data from a single punch press is a necessary first step, but further validation on a rotary press is essential to address high-speed production dynamics.

Choosing the right tablet press is about matching the machine's specific capabilities to your stage in the product development lifecycle.

Summary Table:

| Advantage | Key Benefit | Ideal For |

|---|---|---|

| Minimal Material Consumption | Saves expensive APIs & excipients | Early-stage drug development |

| Simplicity & Ease of Operation | Quick setup, easy cleaning | Fast-paced R&D environments |

| High Precision for Small Batches | Consistent dosing & compression | Feasibility & compressibility studies |

| Compact Size & Low Noise | Fits any lab space, quiet operation | Comfortable laboratory workflows |

Ready to optimize your formulation development with precision and efficiency? KINTEK specializes in high-quality single punch tablet presses designed for laboratory R&D. Our machines help you confirm powder compressibility and test formulations with minimal material waste, accelerating your research timeline. Contact our experts today to find the perfect press for your lab's needs!

Visual Guide

Related Products

- Single Punch Electric Tablet Press Machine Laboratory Powder Tablet Punching TDP Tablet Press

- Lab Scale Rotary Single Punch Tablet Press Machine TDP Tablet Punching Machine

- Manual Lab Heat Press

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Manual Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

People Also Ask

- What is the difference between a rotary tablet press and a single tablet punch press? A Guide to Choosing the Right Machine

- What are the advantages of a rotary tablet machine? Unlock High-Speed, Precise Tablet Production

- What are the advantages of tablet press machine? Achieve High-Speed, Consistent Production

- What is the use of a biomass pellet machine? Turn Waste into Fuel, Feed, and Bedding

- What do you press pills with? The Essential Guide to Tablet Press Machines

- What is the purpose of the pelletizing machine? Transform Waste into Valuable, Dense Pellets

- What is the advantage of a single punch tablet machine? Ideal for Low-Waste R&D and Formulation Testing

- What is a tablet punch? The Precision Tool Shaping Your Tablet Manufacturing