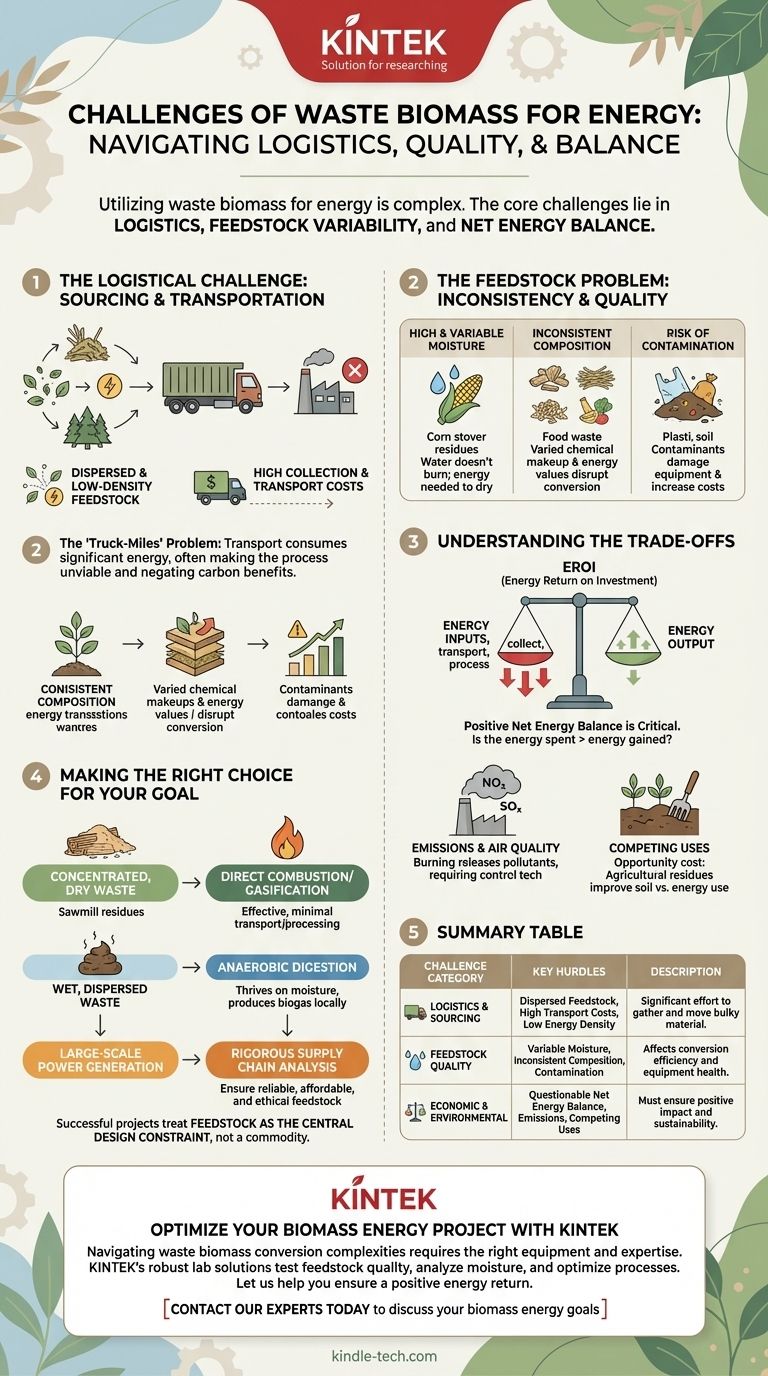

While promising, utilizing waste biomass for energy is not a simple solution. The core challenges are not in the conversion technologies themselves, but in the complex logistics of collection, the inherent variability of the feedstock, and the critical need to ensure a positive net energy balance. Key hurdles include high transportation costs, inconsistent material quality and moisture content, and potential environmental trade-offs that must be carefully managed.

The central challenge of waste biomass energy is overcoming the economic and energetic costs of gathering and processing a fuel source that is, by its nature, dispersed, bulky, and inconsistent. Success hinges on a well-designed supply chain, not just an efficient power plant.

The Logistical Challenge: Sourcing and Transportation

The most immediate and costly problems in biomass energy are rooted in simple logistics. Unlike fossil fuels, which are highly concentrated and transported through established infrastructure, biomass is the opposite.

Dispersed and Low-Density Feedstock

Biomass sources like agricultural residues or forest trimmings are spread over large areas. This low geographic density means significant effort is required just to gather the material.

Furthermore, biomass is bulky and has a low energy density. A truckload of wood chips contains far less potential energy than a tanker of oil, making transportation a major operational bottleneck.

High Collection and Transport Costs

The cost per unit of energy for collecting and moving biomass is often very high. This "truck-miles" problem can consume a substantial portion of the energy you ultimately produce, sometimes making the entire process economically unviable.

The carbon footprint of this transportation network must also be considered. If extensive fossil fuel is used to move the biomass, it can negate the carbon benefits of the fuel itself.

The Feedstock Problem: Inconsistency and Quality

Once the biomass arrives at a facility, its physical and chemical properties present a new set of technical challenges. A power plant is designed for a specific fuel, but waste biomass is rarely uniform.

High and Variable Moisture Content

One of the biggest hurdles is high moisture content. Water does not burn, and energy must be expended to dry the biomass before it can be efficiently converted. For feedstocks like manure or food waste, this energy cost can significantly reduce the net energy gain.

Inconsistent Chemical Composition

Different types of biomass (e.g., wood, straw, corn stover) have different chemical makeups, ash contents, and energy values. This variability can make it difficult to maintain a stable and efficient conversion process, whether through combustion or biological digestion.

Risk of Contamination

Waste biomass streams can be contaminated with soil, rocks, plastics, or other non-combustible materials. These contaminants can damage processing equipment, reduce efficiency, and increase maintenance costs.

Understanding the Trade-offs

A successful biomass project must be evaluated on its net impact. Simply converting waste to energy is not enough; the process must be beneficial after accounting for all inputs and outputs.

The Net Energy Balance Question

A critical question is whether the Energy Return on Investment (EROI) is positive. If you spend more energy collecting, transporting, and processing the biomass than you get out of it, the project is an energy sink, not a source.

Emissions and Air Quality

While biomass is often considered carbon-neutral, its combustion is not emission-free. Burning biomass can release pollutants like nitrogen oxides (NOx), sulfur oxides (SOx), and particulate matter, which can impact local air quality if not controlled with advanced filtering technology.

Competing Uses for Biomass

Waste isn't always waste. Agricultural residues, for instance, can be tilled back into the ground to improve soil health and carbon sequestration. Using them for energy creates an opportunity cost and may degrade soil quality over the long term.

Making the Right Choice for Your Goal

The viability of a waste biomass project depends entirely on aligning the technology with the specific type, quantity, and location of the feedstock.

- If your primary focus is a concentrated, dry waste stream (e.g., sawmill residue): Direct combustion or gasification is often highly effective, as transportation and pre-processing costs are minimal.

- If your primary focus is a wet, dispersed waste stream (e.g., agricultural manure or food waste): Anaerobic digestion is a superior choice, as it thrives on high moisture and produces biogas for localized use, avoiding transport inefficiencies.

- If your primary focus is a large-scale power generation facility: A rigorous supply chain analysis is the most critical first step to ensure your feedstock is reliable, affordable, and ethically sourced for the long term.

Ultimately, successful biomass energy projects treat the feedstock as the central design constraint, not as a simple commodity.

Summary Table:

| Challenge Category | Key Hurdles |

|---|---|

| Logistics & Sourcing | Dispersed feedstock, high transport costs, low energy density |

| Feedstock Quality | Variable moisture content, inconsistent composition, contamination risk |

| Economic & Environmental | Questionable net energy balance (EROI), emissions control, competing land uses |

Optimize Your Biomass Energy Project with KINTEK

Navigating the complexities of waste biomass conversion requires the right equipment and expertise. Whether you're processing agricultural residues, wood chips, or organic waste, KINTEK's robust lab equipment and consumables are designed for testing feedstock quality, analyzing moisture content, and optimizing conversion processes.

We serve laboratories and facilities focused on developing efficient, sustainable energy solutions. Let us help you ensure a positive energy return and overcome technical hurdles.

Contact our experts today to discuss how our solutions can support your biomass energy goals.

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Electric Rotary Kiln Small Rotary Furnace for Activated Carbon Regeneration

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Heating Pyrolysis Plant

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Calciner Small Rotary Kiln Rotating Furnace

People Also Ask

- How flammable is biochar? A Guide to Understanding and Managing Its Fire Risk

- What is the voltage for arcing? It's Not a Single Number—It's About Electric Field Strength

- What are the future trends in additive manufacturing? From Prototyping to Intelligent, Automated Production

- Why is a high-purity hydrogen environment used during the RMA of zirconium alloy? Achieve Precision Powder Processing

- What is the function of laboratory high-temperature ovens? Master Biomass Hydrothermal Conversion Control

- What technical challenges do integrated membrane technologies address? Overcome Mass Transfer in Wastewater Treatment

- Which type of evaporator is used in chemical industry? Choose the Right Evaporator for Your Process

- What is the end product of fast pyrolysis? Maximize Bio-Oil Yield for Renewable Fuel