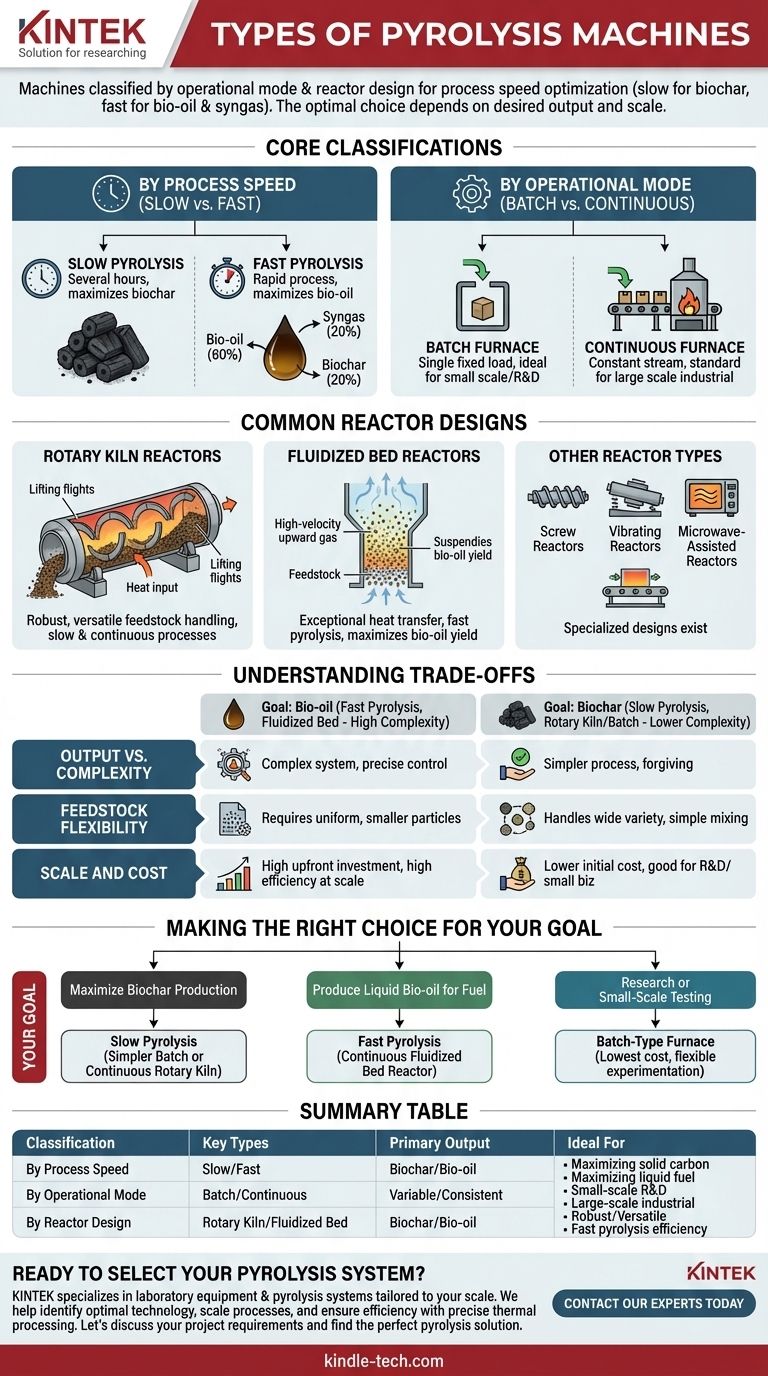

The primary types of pyrolysis machines are categorized by their operational mode (batch or continuous) and their reactor design, with the most common being rotary kiln and fluidized bed reactors. The choice of machine is dictated by the process speed—slow pyrolysis to produce biochar or fast pyrolysis to produce bio-oil and syngas.

The core principle to understand is that there is no single "best" pyrolysis machine. The optimal choice is always a function of your desired output (bio-oil, biochar, or gas) and your operational scale (small-batch testing vs. large-scale industrial processing).

Two Core Classifications: Process vs. Operation

To understand the hardware, you must first understand the two fundamental ways pyrolysis systems are defined: by the speed of the chemical process and the mode of material handling.

By Process Speed (Slow vs. Fast)

The duration of the heating process fundamentally changes the final product.

Slow pyrolysis takes several hours to complete. This extended heating time maximizes the production of biochar, a stable, carbon-rich solid similar to charcoal.

Fast pyrolysis, the more common industrial method, completes in seconds. This rapid process is designed to maximize the yield of liquid bio-oil (around 60%), with smaller amounts of biochar (20%) and syngas (20%) as byproducts.

By Operational Mode (Batch vs. Continuous)

This classification refers to how the raw material, or feedstock, is fed into the system.

A batch furnace processes a single, fixed load of material at a time. This method is ideal for small-scale applications, laboratories, or situations with inconsistent feedstock supply.

A continuous furnace is fed a constant stream of material and runs without interruption. This is the standard for larger, industrial-scale operations where efficiency and consistent output are critical.

Common Pyrolysis Reactor Designs

The reactor is the heart of the machine where the heating occurs. The design dictates how heat is transferred to the feedstock, which impacts efficiency and the final product.

Rotary Kiln Reactors

A rotary kiln is a large, rotating cylindrical vessel. As the cylinder rotates, the feedstock tumbles and mixes, ensuring all material is heated evenly. This robust design is well-suited for both slow and continuous processes.

Fluidized Bed Reactors

These advanced reactors use a high-velocity stream of hot gas (like nitrogen or recycled syngas) from below to suspend and mix the feedstock particles, causing them to behave like a fluid.

This "fluidization" creates exceptional heat transfer, making these reactors the preferred choice for fast pyrolysis where rapid, uniform heating is essential for maximizing bio-oil yield.

Other Reactor Types

While less common, other specialized designs exist. These include screw reactors (augers) that transport material through a heated chamber, vibrating reactors, and even microwave-assisted reactors that use microwave energy for heating.

Understanding the Trade-offs

Choosing a pyrolysis technology involves balancing complexity, cost, and output. Each design comes with inherent advantages and disadvantages.

Output vs. Complexity

If your goal is bio-oil, you need fast pyrolysis, which typically requires a more complex and precisely controlled system like a fluidized bed reactor. If your goal is biochar, a simpler and more forgiving slow pyrolysis process in a rotary kiln or batch furnace is often sufficient.

Feedstock Flexibility

Rotary kilns are generally robust and can handle a wide variety of feedstock sizes and types due to their simple mechanical mixing. Fluidized bed reactors require more uniform, smaller particle sizes to ensure proper fluidization.

Scale and Cost

Batch systems have a lower initial capital cost, making them accessible for research or small businesses. However, continuous systems, despite their high upfront investment, offer superior efficiency and lower per-unit operational costs at an industrial scale.

Making the Right Choice for Your Goal

Your specific objective determines the right technology. Use these points as a guide to align the machine type with your intended outcome.

- If your primary focus is maximizing biochar production: A slow pyrolysis process using a simpler batch furnace or a continuous rotary kiln is your most direct path.

- If your primary focus is producing liquid bio-oil for fuel: You need a fast pyrolysis process, which is best achieved with a continuous fluidized bed reactor.

- If you are in the research or small-scale testing phase: A batch-type furnace offers the lowest cost of entry and the flexibility to experiment with different feedstocks and parameters.

Ultimately, selecting the right pyrolysis machine is about matching the engineering to your specific economic and environmental goals.

Summary Table:

| Classification | Key Types | Primary Output | Ideal For |

|---|---|---|---|

| By Process Speed | Slow Pyrolysis | Biochar | Maximizing solid carbon production |

| Fast Pyrolysis | Bio-oil (60%) | Maximizing liquid fuel yield | |

| By Operational Mode | Batch Furnace | Variable (per batch) | Small-scale, R&D, inconsistent feedstock |

| Continuous Furnace | Consistent Stream | Large-scale, industrial processing | |

| By Reactor Design | Rotary Kiln | Biochar / Bio-oil | Robust, versatile feedstock handling |

| Fluidized Bed | Bio-oil | Fast pyrolysis, high efficiency |

Ready to Select Your Pyrolysis System?

Choosing the right pyrolysis machine is critical to achieving your specific output goals, whether it's bio-oil, biochar, or syngas. KINTEK specializes in providing laboratory equipment and consumables, including pyrolysis systems tailored to your research or production scale.

We can help you:

- Identify the optimal technology (batch, continuous, rotary kiln, fluidized bed) for your feedstock and target products.

- Scale your process from R&D to pilot or full production.

- Ensure efficiency and reliability with equipment designed for precise thermal processing.

Let's discuss your project requirements and find the perfect pyrolysis solution for you.

Contact our experts today to get started!

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- Lab Scale Rotary Single Punch Tablet Press Machine TDP Tablet Punching Machine

- Mini SS High Pressure Autoclave Reactor for Laboratory Use

People Also Ask

- What is the process of biomass fast pyrolysis? Turn Biomass into Bio-Oil in Seconds

- What are the advantages of pyrolysis technology? Turn Waste into Profit and Reduce Emissions

- What are the conditions for biomass pyrolysis? Optimize Temperature, Heating Rate & Time

- Is pyrolysis viable? A Guide to Economic, Technological, and Environmental Success

- How is energy converted into biomass? Harnessing Nature's Solar Power for Renewable Energy