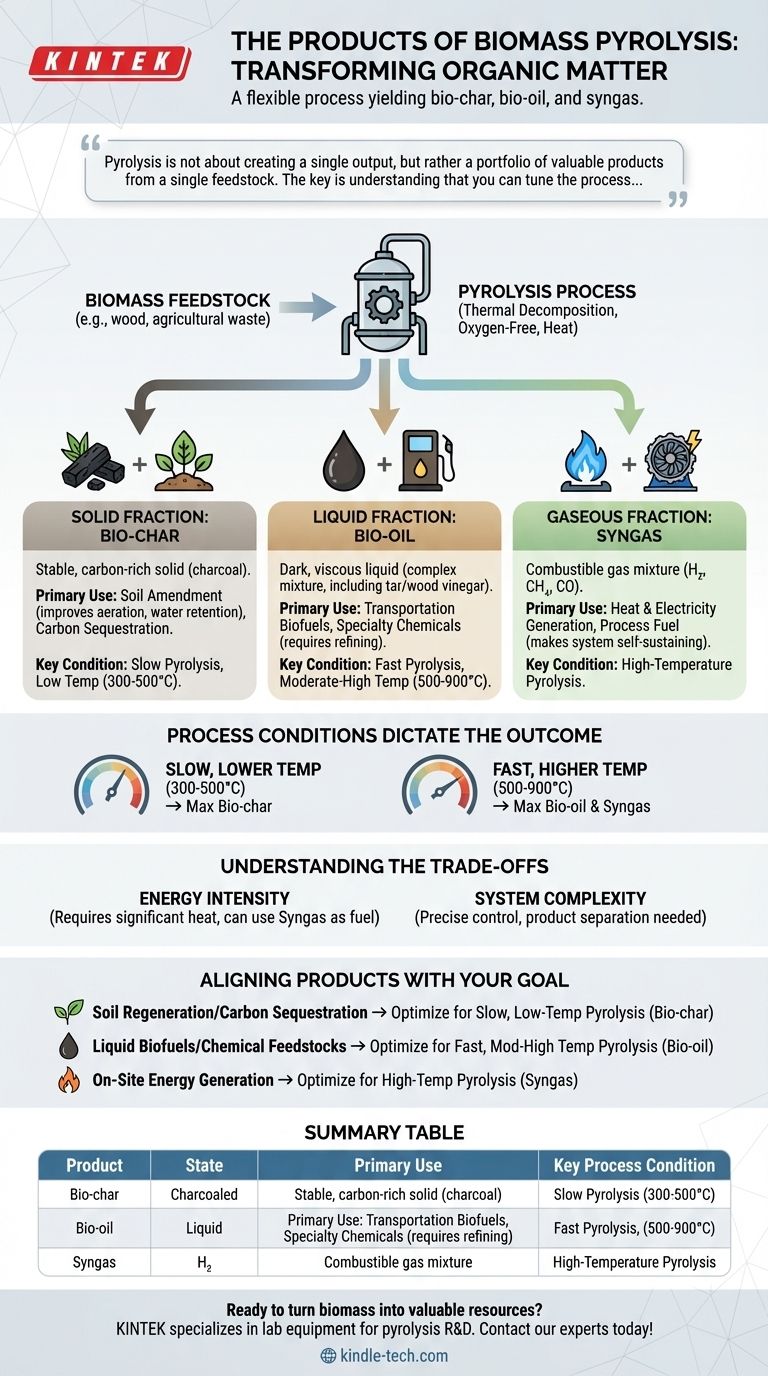

In short, biomass pyrolysis transforms organic material into three distinct product categories. It yields a solid carbon-rich residue called bio-char, a complex liquid mixture known as bio-oil, and a blend of non-condensable gases called syngas. The exact proportion and chemical makeup of these three products depend entirely on the type of biomass used and the specific temperature and speed of the pyrolysis process.

Pyrolysis is not about creating a single output, but rather a portfolio of valuable products from a single feedstock. The key is understanding that you can tune the process—primarily temperature and heating rate—to deliberately favor the production of either solid bio-char, liquid bio-oil, or combustible syngas, depending on your end goal.

The Three Core Products of Pyrolysis

Pyrolysis is a process of thermal decomposition in an oxygen-free environment. By heating biomass, we break down its core components—cellulose, hemicellulose, and lignin—into more basic, useful substances across three states of matter.

The Solid Fraction: Bio-char

Bio-char is the stable, carbon-rich solid that remains after the volatile components of the biomass have been driven off. It is functionally a form of charcoal.

Its primary application is as a soil amendment. The porous structure of bio-char improves soil aeration and water retention, and it provides a stable way to sequester carbon back into the earth for long periods.

The Liquid Fraction: Bio-oil

As the pyrolysis gas cools, a portion of it condenses into a dark, viscous liquid. This is bio-oil, a complex mixture that can also include components like tar and wood vinegar.

This liquid fraction is energy-dense and represents a significant opportunity. With further refining, bio-oil can be upgraded into transportation biofuels and other valuable specialty chemicals.

The Gaseous Fraction: Syngas

The remaining non-condensable gases form what is known as syngas, or synthesis gas. This is a mixture of combustible and non-combustible components.

The valuable combustible gases include hydrogen (H₂), methane (CH₄), and carbon monoxide (CO). The syngas can be combusted directly to generate heat and electricity, often used to power the pyrolysis process itself, making the system more energy-efficient.

How Process Conditions Dictate the Outcome

You cannot get a maximum yield of all three products simultaneously. The output is a direct result of the process conditions you choose, turning pyrolysis into a flexible tool rather than a fixed procedure.

The Critical Role of Temperature

Temperature is the primary lever for controlling the product distribution. The general relationship is straightforward.

Slow, lower-temperature pyrolysis (around 300-500°C) allows more time for carbon to form solid structures, maximizing the yield of bio-char.

Fast, higher-temperature pyrolysis (around 500-900°C) rapidly breaks down the biomass, vaporizing it to maximize the yield of bio-oil and syngas while minimizing the solid residue.

The Influence of Biomass Type

The starting material, or feedstock, also matters. The ratio of cellulose, hemicellulose, and lignin in different types of biomass (e.g., wood chips vs. agricultural straw) will influence the final product composition, as these components decompose at different temperatures and rates.

Understanding the Trade-offs

While powerful, pyrolysis is not a simple solution. It is an engineered process with inherent complexities that must be managed for efficient and reliable operation.

Energy Intensity

Reaching and maintaining pyrolysis temperatures requires a significant energy input. A well-designed system mitigates this by using the syngas it produces as a fuel source to provide the necessary process heat, creating a more self-sustaining operation.

System Complexity

Achieving a consistent, high-quality product requires precise control over temperature, pressure, and processing time. Furthermore, the downstream collection and separation of products—such as condensing the bio-oil and cleaning the syngas—add layers of engineering complexity and cost to the overall system.

Aligning Products with Your Primary Goal

Your approach to pyrolysis should be driven by the product you value most. The process can be optimized to serve distinctly different commercial or environmental objectives.

- If your primary focus is soil regeneration and carbon sequestration: Optimize for slow, lower-temperature pyrolysis to maximize the yield of stable bio-char.

- If your primary focus is producing liquid biofuels or chemical feedstocks: Employ fast pyrolysis at moderate-to-high temperatures to favor the production and capture of bio-oil.

- If your primary focus is on-site energy generation from waste: Configure the system for high temperatures to maximize syngas production, which can then be used to power turbines or provide process heat.

Ultimately, viewing pyrolysis as a flexible refinery, not a fixed process, is the key to converting biomass waste into targeted, high-value resources.

Summary Table:

| Product | State | Primary Use | Key Process Condition |

|---|---|---|---|

| Bio-char | Solid | Soil amendment, carbon sequestration | Slow pyrolysis, low temperature (300-500°C) |

| Bio-oil | Liquid | Biofuel, chemical feedstock | Fast pyrolysis, moderate-high temperature (500-900°C) |

| Syngas | Gas | Heat, electricity, process fuel | High-temperature pyrolysis |

Ready to turn biomass into valuable resources? KINTEK specializes in lab equipment and consumables for pyrolysis research and development. Whether you're optimizing for bio-char, bio-oil, or syngas production, our precise temperature control systems and reactors can help you achieve your goals. Contact our experts today to discuss how we can support your laboratory's biomass conversion projects!

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Laboratory Rapid Thermal Processing (RTP) Quartz Tube Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Vertical Laboratory Tube Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What are the reactions involved in pyrolysis of biomass? Unlock the Chemistry for Tailored Bio-Products

- What are the conditions for biomass pyrolysis? Optimize Temperature, Heating Rate & Time

- What are the different types of pyrolysis machines? Choose the Right System for Your Output

- Is pyrolysis viable? A Guide to Economic, Technological, and Environmental Success

- What are the advantages of pyrolysis technology? Turn Waste into Profit and Reduce Emissions