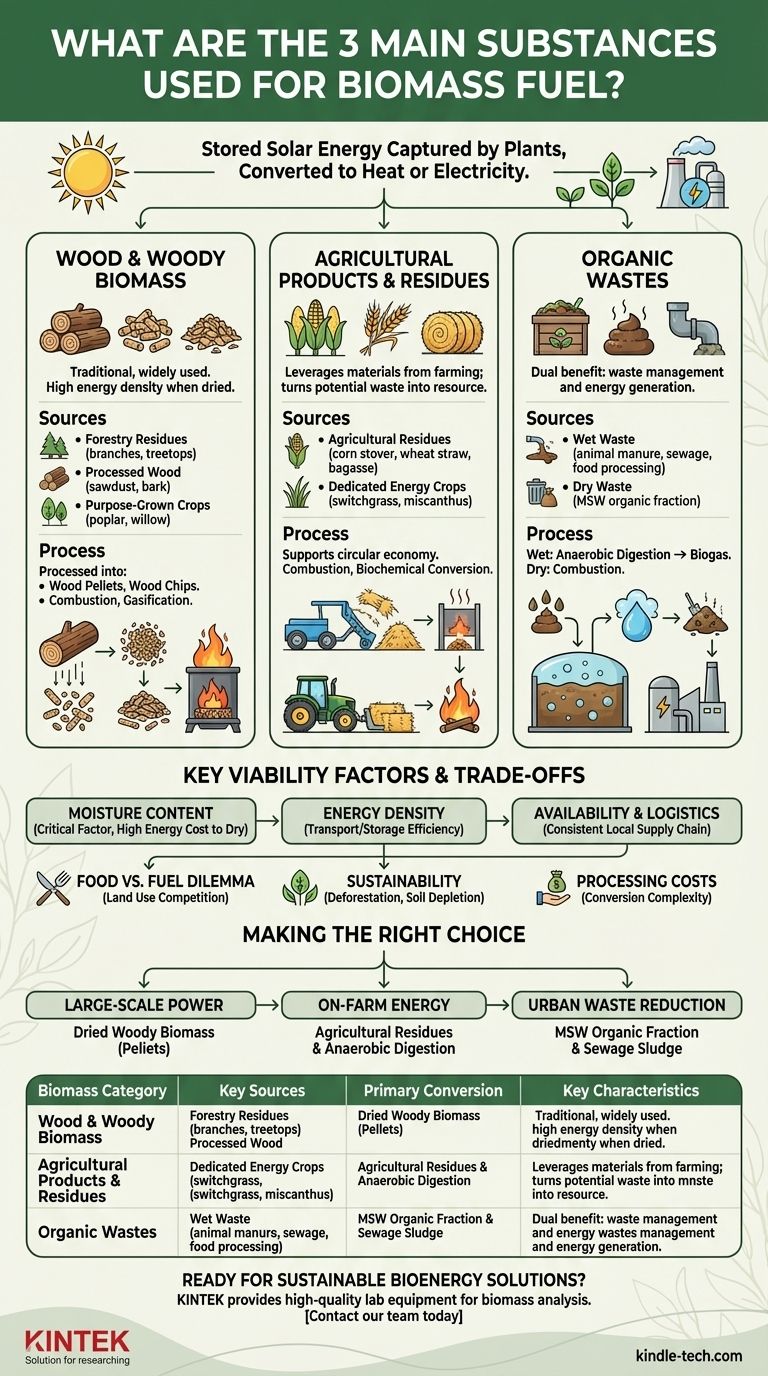

At its core, biomass fuel is derived from three primary categories of organic matter. These are wood and woody biomass, agricultural products and residues, and various organic waste streams. While seemingly distinct, they all represent stored solar energy captured by plants that can be converted into heat or electricity.

The most effective biomass fuel is not a single substance, but rather a category of material chosen based on a critical balance of energy density, moisture content, and the logistics of its supply chain. Understanding this trade-off is key to any successful bioenergy project.

The Three Core Categories of Biomass Fuel

Biomass is a broad term, but virtually all viable fuel sources fall into one of three major classifications. Each has distinct characteristics, sources, and applications.

Wood and Woody Biomass

This is the most traditional and widely used category of biomass fuel, valued for its relatively high energy density when dried.

Sources include forestry residues (like branches and treetops left after logging), processed wood from sawmills (sawdust, bark), and purpose-grown short-rotation woody crops (like poplar or willow). It is often processed into wood pellets or wood chips to create a uniform, dense, and easily transportable fuel.

Agricultural Products and Residues

This category leverages materials generated by the farming sector, turning potential waste into a valuable resource.

It includes agricultural residues, which are the non-food parts of crops like corn stover (stalks, leaves), wheat straw, and sugarcane bagasse. It also includes dedicated energy crops, which are non-food plants like switchgrass or miscanthus grown specifically for their energy content.

Wet and Dry Organic Wastes

This group comprises organic materials that are often treated as waste, providing a dual benefit of waste management and energy generation.

Wet waste, such as animal manure, sewage sludge, and food processing waste, is ideal for anaerobic digestion. This process uses microbes to break down the organic matter and produce biogas (primarily methane), which can be burned for heat or electricity.

Dry waste, particularly the organic portion of municipal solid waste (MSW), can be directly combusted in specialized waste-to-energy plants.

Key Factors That Determine Fuel Viability

Not all biomass is created equal. Three technical factors largely determine whether a given organic material is an economically and energetically viable fuel source.

Moisture Content

Moisture content is the single most critical factor. Before a substance can burn and release energy, any water it holds must be boiled off, which consumes a significant amount of energy.

Fuels with high moisture content (like fresh-cut wood or wet manure) have a low net energy yield. This is why biomass like wood is often dried or pelletized to reduce moisture from over 50% to under 10%.

Energy Density

Energy density refers to the amount of energy stored in a given volume or mass of fuel.

High-density fuels like wood pellets are efficient to transport and store. Low-density fuels like loose straw are bulky and expensive to move long distances, making them suitable only for local, on-farm use unless they are densified into pellets.

Availability and Logistics

A consistent, reliable, and affordable supply chain is non-negotiable. The ideal biomass source is a local byproduct or waste stream.

Relying on biomass that must be transported over long distances can negate the fuel's economic and environmental benefits due to high costs and the carbon footprint of transportation.

Understanding the Critical Trade-offs

While bioenergy is a powerful renewable resource, its application involves important considerations and potential downsides that must be managed responsibly.

The Food vs. Fuel Dilemma

A major concern, particularly with crops like corn used for ethanol, is the "food vs. fuel" debate. Using agricultural land and crops for energy production can potentially compete with food production, impacting global food prices and availability.

Sustainability and Land Use

Sourcing biomass must be done sustainably. Relying on whole trees instead of forestry residues can lead to deforestation. Poor management of energy crops can lead to soil depletion, water pollution, and loss of biodiversity.

Processing and Conversion Costs

The initial state of the biomass dictates the cost and complexity of its conversion. Dry, woody biomass can often be used in simple combustion systems. Wet wastes, however, require investment in more complex technologies like anaerobic digesters to be used effectively.

Making the Right Choice for Your Goal

The optimal biomass source depends entirely on the intended application, scale, and available local resources.

- If your primary focus is large-scale, consistent power generation: Dried woody biomass, especially in pellet form, offers the highest energy density and the most established global supply chains.

- If your primary focus is on-farm energy or decentralized power: Agricultural residues and anaerobic digestion of manure provide a circular solution that manages waste while generating local energy.

- If your primary focus is urban waste reduction and energy recovery: The organic fraction of municipal solid waste and sewage sludge offers a dual benefit, though it requires specialized waste-to-energy facilities.

Ultimately, understanding these core fuel types and their characteristics is the first step toward implementing truly sustainable and effective bioenergy solutions.

Summary Table:

| Biomass Category | Key Sources | Primary Conversion Method | Key Characteristics |

|---|---|---|---|

| Wood & Woody Biomass | Forestry residues, sawmill waste, energy crops (e.g., poplar) | Combustion, gasification | High energy density when dry, established supply chains |

| Agricultural Products & Residues | Crop residues (e.g., corn stover, straw), energy crops (e.g., switchgrass) | Combustion, biochemical conversion | Manages agricultural waste, supports circular economy |

| Organic Wastes | Wet waste (manure, sewage), dry waste (MSW organic fraction) | Anaerobic digestion (wet), combustion (dry) | Dual benefit of waste management and energy recovery |

Ready to implement an efficient and sustainable bioenergy solution for your lab or facility?

Choosing the right biomass fuel is critical for achieving optimal energy output and operational efficiency. KINTEK specializes in providing high-quality lab equipment and consumables for biomass analysis and conversion processes. Whether you are researching fuel properties, developing new biofuels, or scaling up production, our solutions can help you accurately characterize moisture content, energy density, and more.

Let our expertise guide your project to success. Contact our team today to discuss your specific biomass fuel and laboratory equipment needs!

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Heating Pyrolysis Plant

- Graphite Vacuum Furnace IGBT Experimental Graphitization Furnace

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Calciner Small Rotary Kiln Rotating Furnace

- Electric Rotary Kiln Small Rotary Furnace for Activated Carbon Regeneration

People Also Ask

- What are the applications of additive manufacturing in dentistry? Unlock Faster, More Precise Patient Care

- What are the disadvantages of metal iron? Key Limitations and Why We Use Alloys Instead

- What is the time of fast pyrolysis? Unlock Maximum Bio-Oil Yield in Seconds

- What is the purpose of vacuum filtration equipment in gallium leaching? Achieve Rapid Solid-Liquid Separation Efficiency

- What role does an orbital shaker incubator play in uranium bioleaching? Optimize Fungal Acid Secretion with Precision

- What are the principles of physical vapor deposition of thin films? Master the 3-Step Process for High-Purity Coatings

- What is the function of a drying oven in ZrB2-SiC processing? Ensure Defect-Free Ceramic Sintering

- What is the temperature of brazing alloys? Mastering the Critical Liquidus Point for Strong Joints