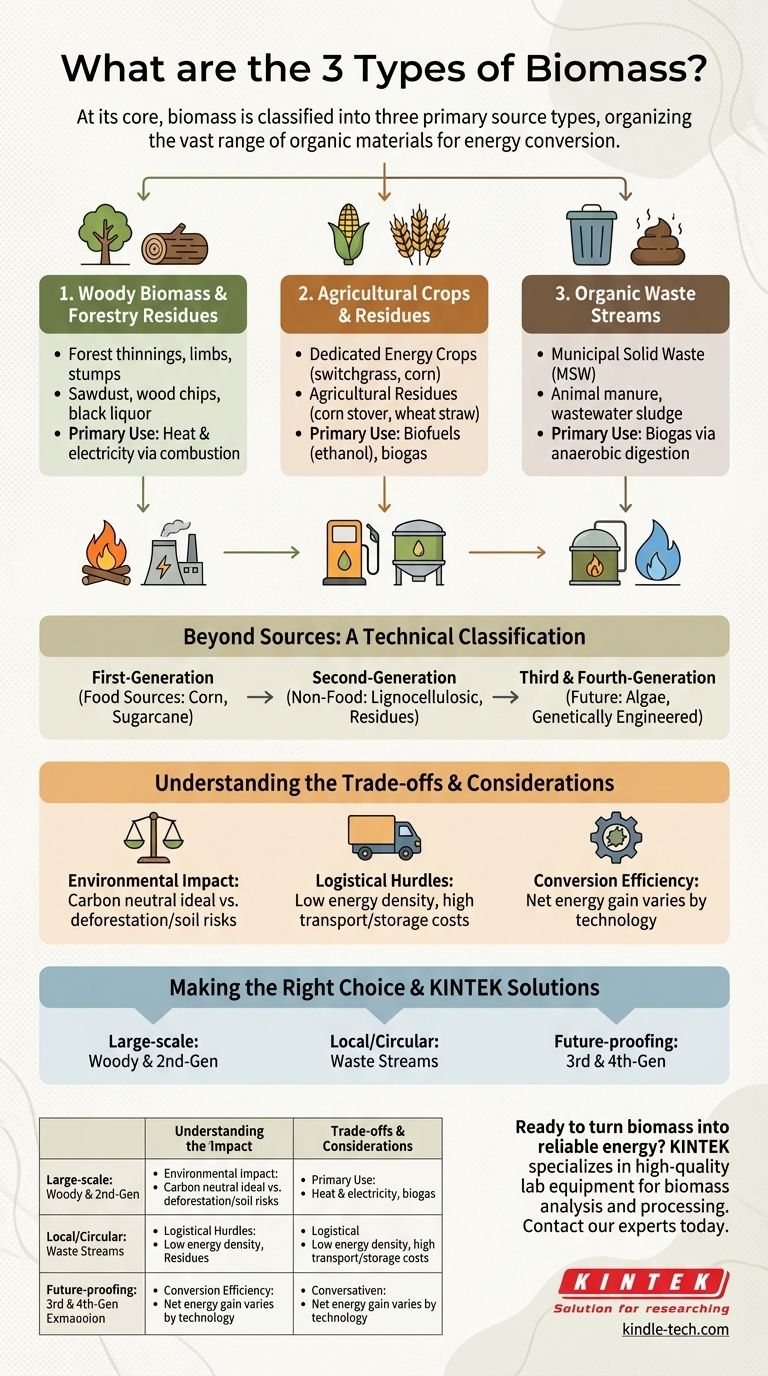

At its core, biomass is most commonly classified into three primary source types. These are woody biomass and agricultural residues, dedicated energy crops, and various forms of organic waste. This framework helps organize the vast range of organic materials that can be converted into energy or other bioproducts.

While thinking of biomass in terms of "wood, crops, and waste" is a useful starting point, the truly critical distinction lies in the material's origin and chemical makeup. These factors ultimately determine its sustainability, economic viability, and best conversion pathway.

A Deeper Look at the Primary Sources

Understanding where biomass comes from is the first step in evaluating its potential. Each category has distinct characteristics, applications, and supply chain considerations.

1. Woody Biomass and Forestry Residues

This is often considered the most traditional form of biomass. It includes materials derived directly from forests and wood processing industries.

Common examples are forest thinnings, limbs, stumps, and damaged trees. It also includes industrial byproducts like sawdust, wood chips, and black liquor from pulp and paper mills. This type is primarily used for direct combustion to produce heat and electricity.

2. Agricultural Crops and Residues

This broad category encompasses materials grown specifically for energy as well as the byproducts of food production.

It can be split into two sub-groups: dedicated energy crops (like switchgrass, poplar, and corn grown for ethanol) and agricultural residues (like corn stover, wheat straw, and rice husks) left over after a harvest.

3. Organic Waste Streams

This category leverages materials that would otherwise be discarded, turning a disposal problem into an energy solution. This is a cornerstone of the circular economy.

Key sources include the organic portion of municipal solid waste (MSW), animal manure from farms, wastewater treatment sludge, and food processing waste. These are often converted into biogas through anaerobic digestion.

Beyond Sources: A More Technical Classification

For technical and policy discussions, particularly concerning sustainability, biomass is often categorized by "generation." This framework addresses the evolution of feedstock development and its impact on food security and land use.

First-Generation: The Food vs. Fuel Dilemma

First-generation biomass refers to feedstocks that are also food sources. The most common examples are corn (for ethanol), sugarcane (for ethanol), and vegetable oils like soy and palm (for biodiesel).

This category faces significant criticism due to its direct competition with the global food supply, which can drive up food prices and raise ethical concerns.

Second-Generation: Utilizing Non-Food Sources

Second-generation biomass is derived from non-food sources, primarily lignocellulosic material. This includes forestry residues, agricultural crop waste, and dedicated non-food energy crops like switchgrass.

The key advantage is that it does not directly compete with food production. However, converting its tough cellular structure (lignin and cellulose) into usable energy is more complex and costly than processing first-generation sugars and starches.

Third and Fourth-Generation: The Future Frontier

Third-generation biomass is focused on algae. Algae can be cultivated in ponds or bioreactors on non-arable land, has extremely high growth rates, and doesn't compete with traditional agriculture.

Fourth-generation biomass involves genetically engineered feedstocks. These are crops or microorganisms designed to have higher energy yields, capture more CO2, or be easier to convert, though they are still in early research phases.

Understanding the Trade-offs

While a renewable resource, biomass is not without its challenges. An objective evaluation requires acknowledging the logistical, economic, and environmental hurdles involved.

Environmental Impact and Sustainability

The idea that biomass is "carbon neutral" is a simplification. While the carbon released during combustion was recently captured from the atmosphere, large-scale harvesting can lead to deforestation, soil degradation, and biodiversity loss if not managed sustainably.

Logistical and Economic Hurdles

Biomass has a low energy density compared to fossil fuels. This means it is bulky and expensive to collect, store, and transport to a processing facility, which can limit the economic viability of a project.

Conversion Efficiency

The process of converting raw biomass into a usable energy form—like electricity, heat, or liquid fuel—is not 100% efficient. The technology used, from direct combustion to gasification or anaerobic digestion, significantly impacts the net energy gain.

Making the Right Choice for Your Goal

Your approach to biomass should be guided by your specific objective. The "best" type of biomass is entirely dependent on the intended application and scale.

- If your primary focus is large-scale, consistent energy generation: Sustainably managed woody biomass and second-generation feedstocks currently offer the most developed and reliable supply chains.

- If your primary focus is local or circular economy solutions: Waste streams like MSW, agricultural residues, and manure provide a powerful way to convert a local liability into a valuable energy asset.

- If your primary focus is future-proofing and technological innovation: Monitor developments in third-generation (algae) and fourth-generation biomass for their potential to overcome the land and water limitations of traditional sources.

Understanding these classifications empowers you to move from simply identifying biomass to strategically applying it for a sustainable purpose.

Summary Table:

| Type of Biomass | Common Examples | Primary Uses |

|---|---|---|

| Woody Biomass & Residues | Forest thinnings, sawdust, wood chips | Heat, electricity via combustion |

| Agricultural Crops & Residues | Switchgrass, corn stover, wheat straw | Biofuels (ethanol), biogas |

| Organic Waste Streams | Municipal solid waste, manure, food waste | Biogas via anaerobic digestion |

Ready to turn biomass into reliable energy for your lab or facility? The right equipment is critical for efficient conversion, whether you're processing woody samples, agricultural residues, or organic waste. KINTEK specializes in high-quality lab equipment and consumables for biomass analysis and processing. From sample preparation to advanced thermal conversion systems, we provide the tools you need for accurate, efficient, and sustainable results. Contact our experts today to discuss your specific biomass application and find the perfect solution for your laboratory needs.

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Calciner Small Rotary Kiln Rotating Furnace

- Electric Rotary Kiln Small Rotary Furnace for Activated Carbon Regeneration

- Evaporation Boat for Organic Matter

- Conductive Carbon Fiber Brush for Static Removal and Cleaning

People Also Ask

- What are the functions of a laboratory stirring system in enhancing the leaching efficiency of gold scrap?

- Why is deposition grouped under physical change? Understanding the Molecular Basis of Phase Transitions

- Why are cold traps considered essential auxiliary equipment in laboratory-scale plastic pyrolysis research? | KINTEK

- What is sintering effect? Transform Powder into Durable, High-Performance Parts

- What is the importance of sintering? Unlock Strength, Density, and Complex Part Production

- Why is a static laboratory testing system necessary? Analyze Refractory Degradation for Copper Smelting

- What are the typical common apparatus used for heating in laboratory? Ensure Safe & Precise Heating

- What factors should be considered when choosing a ULT freezer for a lab? Ensure Maximum Sample Security and Efficiency