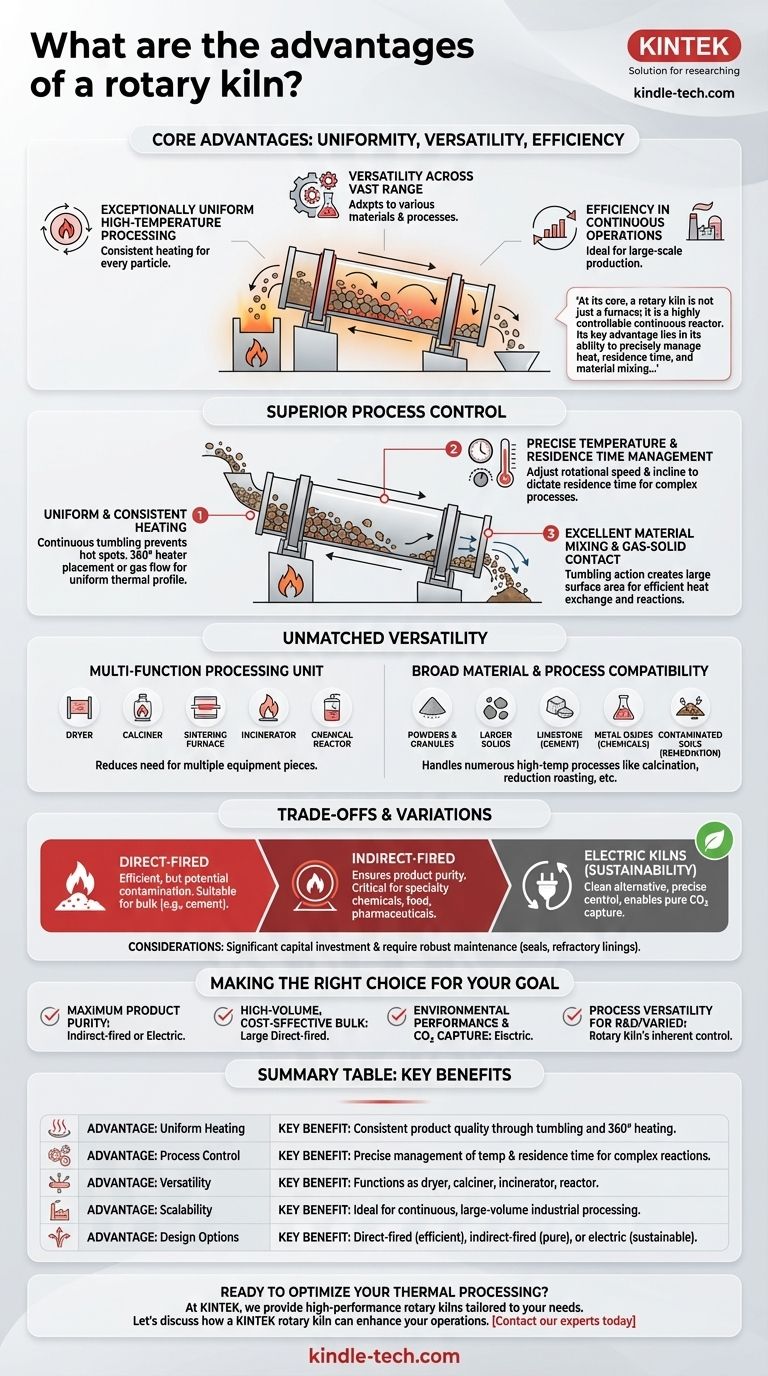

In short, the primary advantages of a rotary kiln are its ability to achieve exceptionally uniform high-temperature processing, its versatility across a vast range of materials and chemical processes, and its efficiency in continuous, large-scale operations. Its unique rotating design ensures that every particle of the material is consistently heated, making it an indispensable tool for industries from cement manufacturing to mineral processing.

At its core, a rotary kiln is not just a furnace; it is a highly controllable continuous reactor. Its key advantage lies in its ability to precisely manage heat, residence time, and material mixing, delivering consistent product quality at an industrial scale.

How a Rotary Kiln Achieves Superior Process Control

The defining benefits of a rotary kiln stem directly from its fundamental design—a long, rotating cylinder set at a slight incline. This simple mechanical concept enables an unparalleled level of control over the thermal processing environment.

Uniform and Consistent Heating

The slow rotation of the kiln cylinder continuously tumbles the solid material within it. This action ensures every particle is exposed to the heat source, preventing hot spots and guaranteeing a homogenous final product.

Many designs feature 360° heater placement or carefully controlled gas flow, creating a uniform thermal profile along the length of the kiln. This allows for precise, staged heating as material travels through.

Precise Temperature and Residence Time Management

Operators can precisely dictate how long the material spends in the kiln—its residence time—by adjusting the kiln's rotational speed and angle of inclination.

This control allows for complex processes where materials must be held at different temperatures for specific durations to achieve the desired chemical reactions or physical changes.

Excellent Material Mixing and Gas-Solid Contact

The tumbling action does more than just heat uniformly; it also thoroughly mixes the material bed. This is critical for processes that require reactions with specific gases.

As the solids cascade, they create a large surface area that facilitates highly efficient heat exchange and reaction with the process gases flowing through the kiln.

The Unmatched Versatility of Rotary Kilns

A rotary kiln is not a single-purpose tool but a platform for a wide array of thermal treatment functions. This adaptability makes it a cornerstone of many heavy industries.

A Multi-Function Processing Unit

The same piece of equipment can function as a dryer, calciner, sintering furnace, incinerator, and chemical reactor. This versatility reduces the need for multiple, separate pieces of unit operation equipment.

Broad Material and Process Compatibility

Rotary kilns are used to process everything from powders and granules to larger solids. This includes raw materials like limestone for cement, metal oxides for chemical production, and contaminated soils for remediation.

They capably handle numerous high-temperature processes, including calcination, reduction roasting, thermal desorption, and organic combustion.

Understanding the Trade-offs and Variations

While powerful, a rotary kiln is not a universal solution. Understanding its variations and inherent complexities is key to leveraging it effectively.

Direct-Fired vs. Indirect-Fired Designs

In a direct-fired kiln, the combustion flames and hot gases come into direct contact with the material. This is highly efficient but can introduce contaminants, making it suitable for bulk materials like cement where purity is not the primary concern.

An indirect-fired kiln heats the outside of the rotating shell, keeping the heat source separate from the process material. This ensures product purity, which is critical for specialty chemicals, foods, or pharmaceuticals.

The Rise of Electric Kilns for Sustainability

Modern electric rotary kilns offer a clean alternative to traditional fossil-fuel-fired units. They eliminate emissions at the point of use and provide extremely precise temperature control.

Critically, they allow for the capture of pure CO2 released from the process material itself (e.g., from limestone calcination), which can then be sold or sequestered.

Considerations for Capital and Maintenance

Rotary kilns are large, heavy-duty industrial machines. They represent a significant capital investment and require a robust, preventative maintenance program to ensure reliability and manage operational wear and tear on components like seals and refractory linings.

Making the Right Choice for Your Goal

Selecting the right kiln configuration depends entirely on your process requirements and priorities.

- If your primary focus is maximum product purity: An indirect-fired kiln, particularly an electric model, is the superior choice as it prevents contamination from combustion gases.

- If your primary focus is high-volume, cost-effective bulk processing: A large, direct-fired rotary kiln remains the industry standard for its high thermal efficiency and throughput.

- If your primary focus is environmental performance and CO2 capture: An electric rotary kiln is the only design that effectively isolates process CO2 for capture while eliminating local emissions.

- If your primary focus is process versatility for R&D or varied production: The inherent process control of a rotary kiln makes it ideal for handling diverse materials and reactions.

Ultimately, the rotary kiln's advantages make it the definitive technology for any continuous process requiring precise control over the thermal treatment of solid materials.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Uniform Heating | Ensures consistent product quality through material tumbling and 360° heating. |

| Process Control | Precise management of temperature and residence time for complex reactions. |

| Versatility | Functions as a dryer, calciner, incinerator, and reactor for various materials. |

| Scalability | Ideal for continuous, large-volume industrial processing. |

| Design Options | Direct-fired (efficient), indirect-fired (pure), or electric (sustainable). |

Ready to optimize your thermal processing?

At KINTEK, we specialize in providing high-performance rotary kilns and other lab equipment tailored to your specific needs. Whether you're in cement production, mineral processing, or developing specialty chemicals, our solutions deliver the precise control, efficiency, and reliability you require.

Let's discuss how a KINTEK rotary kiln can enhance your operations. Contact our experts today for a personalized consultation!

Visual Guide

Related Products

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Calciner Small Rotary Kiln Rotating Furnace

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Heating Pyrolysis Plant

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Rotary Tube Furnace Split Multi Heating Zone Rotating Tube Furnace

- Electric Rotary Kiln Small Rotary Furnace for Activated Carbon Regeneration

People Also Ask

- What are the products of pyrolysis of wood? A Guide to Biochar, Bio-oil, and Syngas Yields

- What are the types of pyrolysis reactors used in industry? Choose the Right Technology for Your Product

- What are the industrial applications of pyrolysis? Transform Waste into Energy and Valuable Products

- What is the principle of rotary kiln? Mastering Continuous Thermal Processing

- What equipment is used in pyrolysis? Choosing the Right Reactor for Your Feedstock and Products