The primary advantages of plastic pyrolysis are its ability to convert non-recyclable plastic waste into valuable products like synthetic oil and gas, its significant reduction of landfill volume, and its creation of a circular pathway for materials that would otherwise be lost. This process chemically breaks down plastics, offering a powerful alternative for waste streams that mechanical recycling cannot handle.

Pyrolysis is a form of advanced, or chemical, recycling that transforms complex plastic waste from an environmental liability into a valuable resource, closing the loop in a circular economy and reducing our dependence on virgin fossil fuels.

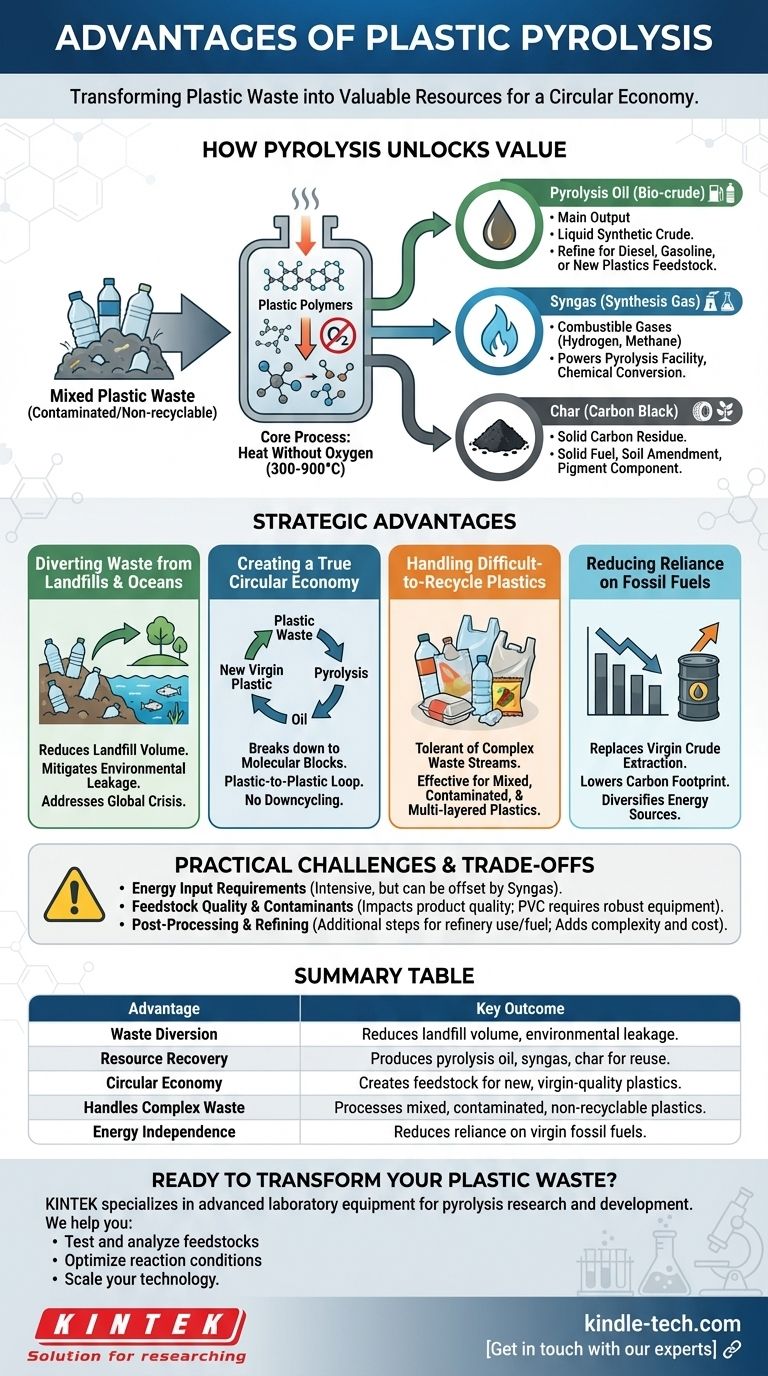

How Pyrolysis Unlocks Value from Plastic Waste

To understand its advantages, we must first understand the core process. Pyrolysis is not burning; it is a fundamental chemical transformation.

The Core Process: Heat Without Oxygen

Pyrolysis involves heating plastic waste to high temperatures (typically 300-900°C) in an environment with little to no oxygen.

The absence of oxygen is critical. It prevents the plastic from combusting and instead causes its long polymer chains to break down into smaller, simpler molecules.

The Key Outputs: From Waste to Resource

This thermal decomposition process yields three primary products, each with its own value.

- Pyrolysis Oil (Bio-crude): This is the main output, a liquid synthetic crude oil. It can be refined into diesel, gasoline, or used as a feedstock to create new plastics.

- Syngas (Synthesis Gas): This is a mixture of combustible gases (like hydrogen and methane). It can be used to power the pyrolysis facility itself, making the process more energy-efficient, or it can be converted into other chemicals.

- Char (Carbon Black): This solid, carbon-rich residue is similar to charcoal. It can be used as a solid fuel, an agricultural soil amendment (biochar), or as a component in products like tires and pigments.

The Strategic Advantages of Pyrolysis

By converting waste into these outputs, pyrolysis offers significant environmental and economic benefits.

Diverting Waste from Landfills and Oceans

Pyrolysis provides a definitive end-of-life solution for plastics that are otherwise destined for landfills or, worse, leakage into the environment. This directly addresses the global plastic waste crisis.

Creating a True Circular Economy

Instead of downcycling plastic into lower-quality goods, pyrolysis breaks it back down to its molecular building blocks. This oil can then be used to manufacture new, virgin-quality plastics, creating a true plastic-to-plastic loop.

Handling Difficult-to-Recycle Plastics

Traditional mechanical recycling struggles with mixed plastics, contaminated materials (e.g., food residue), and multi-layered packaging. Pyrolysis is far more tolerant of these complex waste streams, making it a vital tool for managing real-world waste.

Reducing Reliance on Fossil Fuels

Every barrel of pyrolysis oil produced from plastic waste is a barrel of virgin crude oil that does not need to be extracted from the ground. This reduces the carbon footprint associated with both oil extraction and plastic production.

Understanding the Practical Challenges and Trade-offs

While powerful, pyrolysis is not a silver bullet. An objective assessment requires understanding its limitations.

Energy Input Requirements

The process is energy-intensive, requiring significant thermal energy to reach and maintain high operating temperatures. However, using the syngas produced on-site can offset a substantial portion of this energy demand.

Feedstock Quality and Contaminants

The quality and consistency of the plastic feedstock directly impact the quality of the final products. Contaminants like PVC can release corrosive acids, requiring more robust and expensive equipment.

Post-Processing and Refining

Pyrolysis oil is not a drop-in replacement for crude oil. It often requires further processing and refining to remove impurities before it can be used in conventional refineries or as a fuel, which adds complexity and cost to the overall process.

Making the Right Choice for Your Goal

Pyrolysis is a strategic technology best applied to specific waste management and resource recovery goals.

- If your primary focus is waste volume reduction: Pyrolysis is one of the most effective methods available for diverting mixed and contaminated plastics from landfills.

- If your primary focus is creating new plastics: The technology provides a direct pathway for turning old plastic back into a high-quality feedstock for new plastic production.

- If your primary focus is alternative fuel production: Pyrolysis efficiently converts the stored energy in plastic waste into a liquid fuel, diversifying energy sources away from virgin extraction.

Ultimately, pyrolysis offers a sophisticated chemical solution to a complex material problem, transforming our perception of plastic waste from refuse into a resource.

Summary Table:

| Advantage | Key Outcome |

|---|---|

| Waste Diversion | Reduces landfill volume and environmental leakage |

| Resource Recovery | Produces pyrolysis oil, syngas, and char for reuse |

| Circular Economy | Creates feedstock for new, virgin-quality plastics |

| Handles Complex Waste | Processes mixed, contaminated, and non-recyclable plastics |

| Energy Independence | Reduces reliance on virgin fossil fuels |

Ready to transform your plastic waste into a valuable resource?

KINTEK specializes in advanced laboratory equipment and consumables for pyrolysis research and development. Whether you are optimizing your process, analyzing feedstock, or scaling up production, our precise and reliable tools are designed to support your innovation in chemical recycling.

We help you:

- Test and analyze plastic feedstocks and pyrolysis outputs with accuracy.

- Optimize reaction conditions for maximum yield and efficiency.

- Scale your technology from lab bench to pilot plant with confidence.

Contact us today to discuss how our solutions can enhance your pyrolysis projects and contribute to a more sustainable future. Get in touch with our experts

Visual Guide

Related Products

- Powerful Plastic Crusher Machine

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- High Performance Laboratory Freeze Dryer for Research and Development

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- High Performance Laboratory Freeze Dryer

People Also Ask

- What is conventional pyrolysis? A Guide to Slow Pyrolysis for Biochar Production

- How long is a cement rotary kiln? Optimizing Length for Maximum Efficiency & Output

- What is a carbon regeneration kiln? Reuse Spent Carbon to Cut Costs & Waste

- Does pyrolysis release heat? Understanding the Net Endothermic Process for Efficient Reactor Design

- What is the energy efficiency of a rotary kiln? Achieve Over 95% with the Right Design

- What is biochar processing? Mastering Slow Pyrolysis for Soil Enhancement & Carbon Sequestration

- What is a rotary kiln used for? Mastering Uniform High-Temperature Processing

- How does a rotary kiln rotate? Discover the Core Mechanics That Drive Thermal Processing