In short, the primary advantages of sputtering over evaporation are superior film quality and process control. Sputtering produces films with significantly better adhesion, higher density, and greater uniformity. It achieves this by using high-energy ions to physically dislodge atoms from a target material, ensuring they embed firmly onto the substrate.

The decision between sputtering and evaporation is a fundamental trade-off. Sputtering prioritizes the structural integrity and performance of the coating, whereas evaporation often prioritizes the speed and simplicity of deposition. Understanding this core difference is key to selecting the right method.

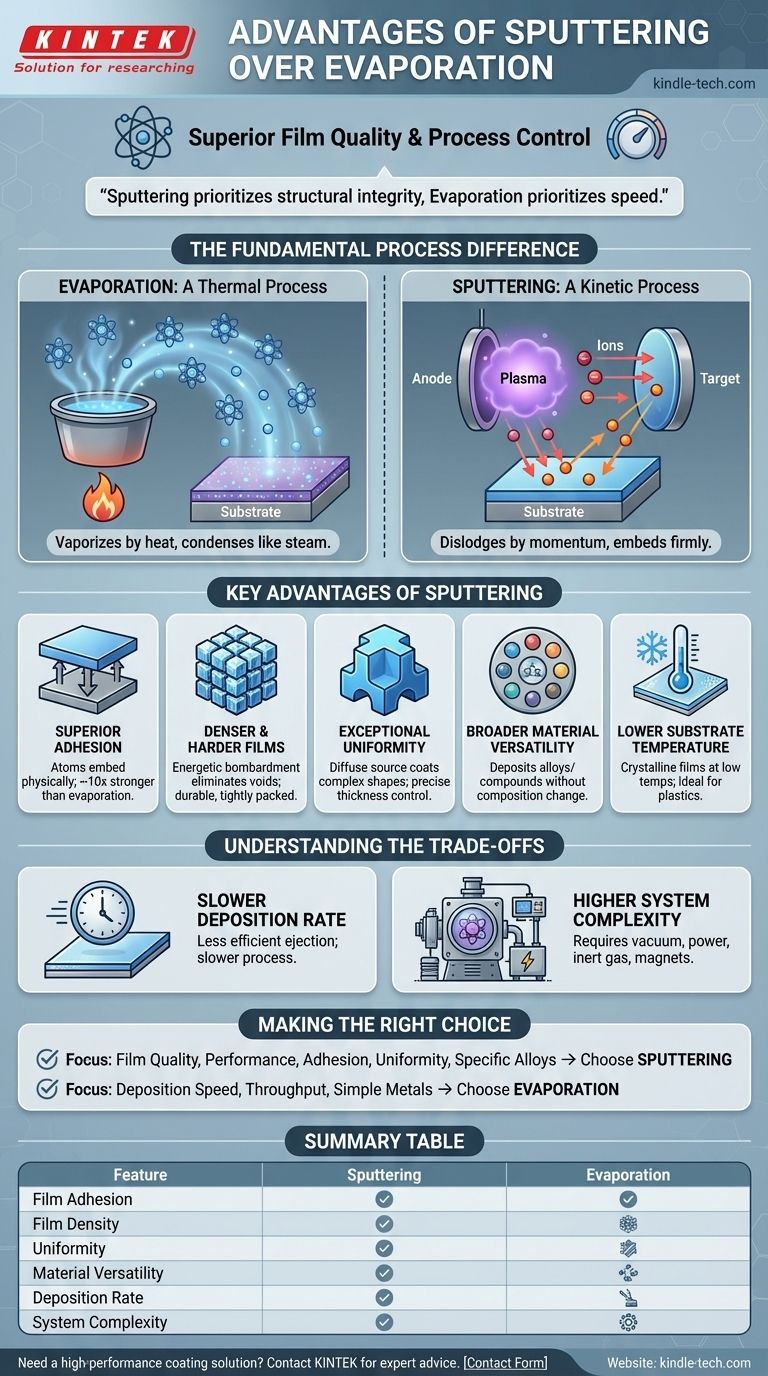

The Fundamental Process Difference

Both sputtering and evaporation are forms of Physical Vapor Deposition (PVD), but they generate vapor through entirely different mechanisms. This difference is the source of their respective advantages and disadvantages.

Evaporation: A Thermal Process

Evaporation uses heat to raise a source material's temperature in a vacuum until it vaporizes. The vaporized atoms then travel through the chamber and condense on the cooler substrate, forming a thin film. This is analogous to boiling water and letting the steam condense on a cold surface.

Sputtering: A Kinetic Process

Sputtering, by contrast, is a momentum-transfer process. It uses a plasma to create high-energy ions (typically argon) that are accelerated into a source material, known as the "target." These collisions have enough force to knock atoms loose from the target, which then travel and deposit onto the substrate.

Key Advantages of Sputtering

The high kinetic energy of the sputtered particles is responsible for most of the technique's benefits, resulting in higher-performance films.

Superior Film Adhesion

The atoms arriving at the substrate during sputtering have significantly higher energy than those from evaporation. This energy helps them physically embed into the substrate surface, creating a much stronger bond.

Adhesion strength for sputtered films can be 10 times greater than for evaporated films.

Denser and Harder Films

The energetic bombardment during deposition helps eliminate voids and create a more tightly packed atomic structure. This results in films that are inherently denser, harder, and more durable than their evaporated counterparts.

Exceptional Uniformity and Thickness Control

Sputtering provides a more diffuse and less "line-of-sight" deposition source. This allows for excellent coating coverage, even on substrates with complex or irregular shapes.

The process is also highly controllable, allowing for precise management of film thickness and uniformity across large areas, which is critical for many optical and electronic applications.

Broader Material Versatility

Sputtering can deposit a wider range of materials, including alloys and compounds. Because atoms are dislodged physically rather than boiled off, the composition of the deposited film remains true to the source target.

Evaporating an alloy can be difficult, as the constituent elements often have different boiling points, leading to an inconsistent film composition.

Lower Substrate Temperature

While the sputtered particles themselves are high-energy, the overall process does not require heating the substrate to high temperatures. Crystalline films can be achieved at much lower temperatures than with evaporation, making sputtering ideal for coating heat-sensitive materials like plastics.

Understanding the Trade-offs

Sputtering is not the superior choice for every situation. Its primary disadvantages are rooted in its speed and complexity.

Slower Deposition Rate

The main drawback of sputtering is its slower deposition rate. The process of ejecting atoms via ion bombardment is inherently less efficient than boiling a material directly.

For applications requiring thick films or high-throughput production, evaporation is often the faster and more economical choice.

Higher System Complexity

Sputtering systems require vacuum chambers, high-voltage power supplies, inert gas handling, and often magnetic fields (in magnetron sputtering) to control the plasma. This makes the equipment more complex and generally more expensive than a simple thermal evaporator.

Making the Right Choice for Your Application

Selecting the correct method requires aligning the process capabilities with your project's most critical outcome.

- If your primary focus is film quality and performance: Choose sputtering for its superior adhesion, density, and uniformity.

- If your primary focus is deposition speed and throughput: Choose evaporation, especially for simpler metal coatings.

- If your primary focus is coating a complex-shaped part: Choose sputtering for its ability to provide uniform coverage.

- If your primary focus is depositing a specific alloy or compound: Choose sputtering to ensure the film's composition matches the source material.

Ultimately, your choice depends on whether the end-use application demands the high-performance film characteristics that sputtering delivers.

Summary Table:

| Feature | Sputtering | Evaporation |

|---|---|---|

| Primary Advantage | Superior Film Quality & Control | High Deposition Speed & Simplicity |

| Film Adhesion | Excellent (10x stronger) | Good |

| Film Density | High, Dense, Durable | Lower, Porous |

| Uniformity | Excellent on complex shapes | Line-of-sight limited |

| Material Versatility | High (alloys, compounds) | Limited (elemental) |

| Deposition Rate | Slower | Faster |

| System Complexity | Higher | Lower |

Need a high-performance coating solution for your lab?

Choosing the right deposition method is critical for your application's success. The experts at KINTEK specialize in lab equipment and consumables, helping you select the ideal sputtering or evaporation system to achieve the film quality, adhesion, and uniformity your research demands.

Contact our team today to discuss your specific requirements and discover how our solutions can enhance your laboratory's capabilities.

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Evaporation Boat for Organic Matter

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Hemispherical Bottom Tungsten Molybdenum Evaporation Boat

- Aluminized Ceramic Evaporation Boat for Thin Film Deposition

People Also Ask

- Can silicon be sputtered? A Guide to RF & DC Methods for Thin Film Deposition

- What is the role of hydrogen in graphene growth? Master the Dual Role for High-Quality Films

- Is diamond coating permanent? The Truth About Its Long-Lasting Durability

- What is sputter coating SEM? Achieve Clear, High-Resolution Imaging for Non-Conductive Samples

- What is the synthesis and mechanism involved in the preparation of carbon nanotubes using CVD process? Master Controlled Growth for Your Application

- Why carbon nanotubes are used in catalyst systems? Enhance Efficiency with Superior Catalyst Support

- Why are carbon nanotubes good for electronics? Unlocking Next-Generation Speed and Efficiency

- What materials are used in optical coating? A Guide to Metal Oxides, Fluorides, and More