In short, waste plastic pyrolysis is a thermochemical process that converts plastic waste into valuable products, primarily a liquid fuel known as pyrolysis oil. It addresses the plastic waste crisis by turning a low-value environmental liability into a high-value economic asset, effectively closing the loop on plastic life cycles and reducing our reliance on virgin fossil fuels.

The fundamental advantage of pyrolysis is not merely waste destruction, but value creation. It reframes plastic waste as a recoverable resource, offering a pragmatic pathway toward a circular economy by converting it into liquid energy and chemical feedstocks that are easy to store and transport.

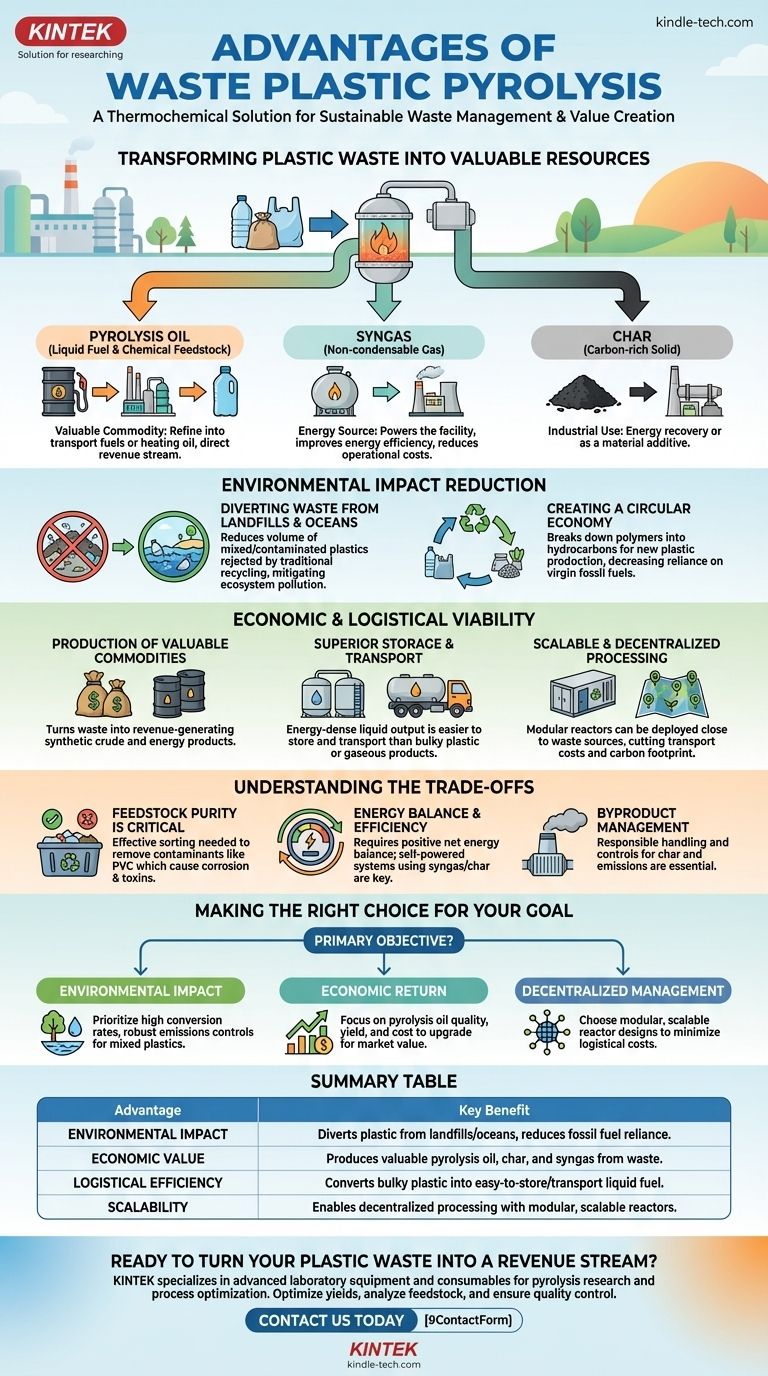

Environmental Impact Reduction

The most cited benefit of plastic pyrolysis is its potential to significantly mitigate environmental damage caused by plastic waste.

Diverting Waste from Landfills and Oceans

Pyrolysis provides a powerful alternative to landfilling or incineration. By processing plastics that are difficult to recycle through traditional mechanical means, it directly reduces the volume of waste that could otherwise pollute land and water ecosystems for centuries.

This process is particularly effective for mixed or contaminated plastic streams that would typically be rejected by conventional recycling centers.

Creating a Circular Economy for Plastics

Pyrolysis breaks down long polymer chains into simpler hydrocarbons, essentially reversing the manufacturing process. These hydrocarbons can be used as a feedstock to create new plastics or other chemicals.

This creates a circular economy, where waste plastic is used to produce virgin-quality materials, decreasing the need to extract and refine new petroleum resources.

Economic and Logistical Viability

Beyond the environmental benefits, pyrolysis presents a compelling economic and operational case for waste management.

Production of Valuable Commodities

The primary output, pyrolysis oil, is a synthetic crude oil. It can be refined into transportation fuels like diesel and gasoline or used as a heating oil, creating a direct revenue stream from waste.

Other outputs, like char (a carbon-rich solid) and syngas (a non-condensable gas), can often be used to power the pyrolysis facility itself, improving its energy efficiency and reducing operational costs.

Superior Storage and Transport Logistics

The liquid pyrolysis oil is far more energy-dense and easier to handle than raw plastic waste or the gaseous products of other thermal treatments. This liquid can be stored in simple tanks and transported efficiently by truck, rail, or pipeline.

This logistical advantage allows for a more flexible and economically sound operational model.

Scalable and Decentralized Processing

Pyrolysis reactors can be built at various scales, from large, centralized plants to smaller, modular units. This scalability is a key advantage.

Small, even mobile, facilities can be deployed close to the source of waste, such as in rural communities or at large industrial sites. This decentralized model drastically cuts down on the costs and carbon footprint associated with transporting bulky plastic waste over long distances.

Understanding the Trade-offs

While promising, pyrolysis is not a silver bullet. A clear-eyed view of its challenges is essential for successful implementation.

Feedstock Purity is Critical

The composition of the plastic waste (feedstock) significantly impacts the process. The presence of materials like PVC is highly problematic, as it releases chlorine that can create corrosive hydrochloric acid and toxic dioxins.

Effective sorting and pre-treatment of plastic waste are often necessary to ensure a clean feedstock, which adds complexity and cost to the operation.

Energy Balance and Efficiency

Pyrolysis is an endothermic process, meaning it requires a significant energy input to heat the plastic in the absence of oxygen. The overall viability depends on a positive net energy balance, where the energy value of the outputs exceeds the energy required to run the process.

Well-designed systems achieve this by using the syngas and char co-products to self-power the reactor.

Byproduct Management

Not all of the plastic waste is converted into valuable liquid oil. The resulting char and non-condensable gases must be managed responsibly. While they can be used for energy, their handling and potential emissions require careful engineering and environmental controls.

Making the Right Choice for Your Goal

When evaluating plastic pyrolysis, your primary objective will determine your focus.

- If your primary focus is environmental impact: Prioritize systems that demonstrate a high conversion rate for mixed plastics and have robust emissions controls to manage byproducts effectively.

- If your primary focus is economic return: Focus on the quality and yield of the pyrolysis oil produced, as its market value and the cost to upgrade it will be the largest driver of profitability.

- If your primary focus is decentralized waste management: Look for modular, scalable reactor designs that minimize logistical costs by processing waste close to its source.

Ultimately, plastic pyrolysis stands as a powerful tool for transforming our relationship with waste, offering a pragmatic way to recover value from a persistent global challenge.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Environmental Impact | Diverts plastic from landfills/oceans, reduces fossil fuel reliance. |

| Economic Value | Produces valuable pyrolysis oil, char, and syngas from waste. |

| Logistical Efficiency | Converts bulky plastic into easy-to-store/transport liquid fuel. |

| Scalability | Enables decentralized processing with modular, scalable reactors. |

Ready to turn your plastic waste into a revenue stream?

KINTEK specializes in advanced laboratory equipment and consumables for pyrolysis research and process optimization. Whether you are developing a new pyrolysis process or scaling up an existing operation, our precise tools can help you analyze feedstock, optimize yields, and ensure quality control.

Contact us today via our [#ContactForm] to discuss how our solutions can support your journey towards a profitable and sustainable circular economy for plastics.

Visual Guide

Related Products

- Twin Screw Extruder Plastic Granulation Machine

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Laboratory Test Sieves and Sieving Machines

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- Benchtop Laboratory Vacuum Freeze Dryer

People Also Ask

- What is the meaning of blowing film? A Guide to Biaxial Orientation and Stronger Plastic Films

- How does extrusion work step by step? A Guide to the Continuous Manufacturing Process

- What is the function of a stainless steel high-pressure reactor in PMMA/hBN synthesis? Achieve Precise Polymeric Control

- What machine is used to make pellets? The Complete Guide to Pellet Mills & Production Systems

- What is the screw extrusion process? A Guide to Continuous Plastic Profiling