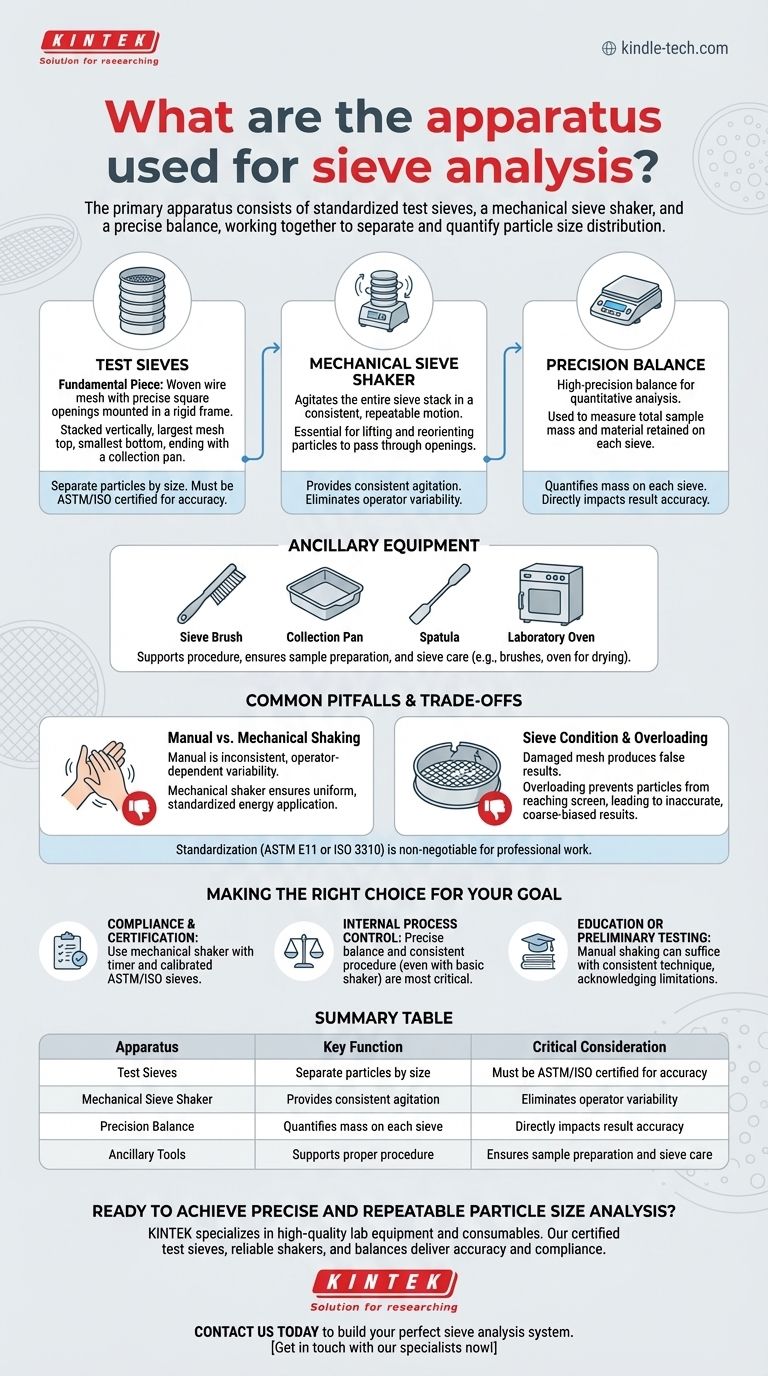

The primary apparatus for sieve analysis consists of a set of standardized test sieves, a mechanical sieve shaker, and a precise balance or scale. These core components work together to physically separate and quantify the particle size distribution of a granular material.

The equipment used for sieve analysis is not merely a collection of tools, but a standardized system. The ultimate goal of this system is to provide accurate, repeatable, and comparable data on particle size, which is critical for quality control in industries from civil engineering to food production.

The Core Apparatus: A Detailed Breakdown

To understand the process, you must first understand the function of each individual component. The precision of the final result depends entirely on the quality and proper use of this equipment.

Test Sieves

A test sieve is the most fundamental piece of the apparatus. It consists of a screen, typically made of woven wire mesh with precisely sized and uniform square openings, mounted in a rigid circular frame.

Sieves are stacked vertically to form a sieve stack. This stack is arranged with the largest mesh opening at the top and progressively smaller openings in each subsequent sieve, ending with a solid collection pan at the bottom. A lid is placed on top to prevent loss of material during shaking.

Mechanical Sieve Shaker

A sieve shaker is a machine designed to agitate the entire sieve stack in a consistent and repeatable motion. This agitation lifts and reorients the particles, giving each one an opportunity to pass through the sieve openings.

While manual shaking is possible, a mechanical shaker is essential for professional applications as it eliminates variability between tests and operators, ensuring a uniform and standardized level of energy is applied to the sample.

Balance or Scale

A high-precision balance is critical for the quantitative aspect of the analysis. It is used twice in the process: first, to measure the total mass of the initial, dry sample, and second, to weigh the material retained on each individual sieve after shaking. The accuracy of the balance directly impacts the accuracy of the final particle size distribution report.

Ancillary Equipment

In addition to the core components, several other tools are necessary for proper procedure. These include sieve brushes (for cleaning meshes without damaging them), collection pans, spatulas for handling material, and often an oven for drying the sample to a constant weight before testing.

Understanding the Trade-offs and Common Pitfalls

Simply having the equipment is not enough. Understanding its limitations and potential sources of error is what separates a novice from an expert.

Manual Shaking vs. Mechanical Shaker

Manual shaking is inexpensive but introduces significant operator-dependent variability. It is nearly impossible to replicate the exact motion, intensity, and duration of shaking by hand, leading to inconsistent results. A mechanical shaker provides the repeatability necessary for quality control and certification.

Sieve Condition and Overloading

The condition of the sieves is paramount. Damaged, distorted, or clogged mesh openings will produce false results. Sieves must be handled carefully, cleaned with appropriate brushes, and inspected regularly for damage.

Furthermore, overloading a sieve with too much material is a common mistake. This prevents particles from reaching the screen surface, leading to an inaccurate and artificially coarse-biased result. Each sieve standard (like ASTM) specifies a maximum permissible load.

Importance of Standardization

The use of certified sieves that conform to standards like ASTM E11 or ISO 3310 is non-negotiable for professional work. These standards dictate strict tolerances for mesh openings, ensuring that a "No. 40" sieve from one manufacturer performs identically to a "No. 40" sieve from another.

Making the Right Choice for Your Goal

The specific apparatus you prioritize depends on your objective.

- If your primary focus is compliance and certification: You must use a mechanical shaker with a timer and a complete set of calibrated, ASTM or ISO-certified sieves.

- If your primary focus is internal process control: A precise balance and a consistent procedure (even with a basic shaker) are most critical for detecting variations over time.

- If your primary focus is education or preliminary testing: Manual shaking can suffice, but you must acknowledge its inherent limitations and focus on maintaining a consistent technique to get roughly comparable results.

Properly using this system of apparatus is the foundation for reliable material characterization and informed engineering decisions.

Summary Table:

| Apparatus | Key Function | Critical Consideration |

|---|---|---|

| Test Sieves | Separate particles by size | Must be ASTM/ISO certified for accuracy |

| Mechanical Sieve Shaker | Provides consistent agitation | Eliminates operator variability |

| Precision Balance | Quantifies mass on each sieve | Directly impacts result accuracy |

| Ancillary Tools | Supports proper procedure (e.g., brushes, oven) | Ensures sample preparation and sieve care |

Ready to achieve precise and repeatable particle size analysis?

KINTEK specializes in high-quality lab equipment and consumables for all your laboratory needs. Our range of certified test sieves, reliable mechanical sieve shakers, and precision balances are designed to deliver the accuracy and compliance your quality control demands.

Contact us today to discuss your application and let our experts help you build the perfect sieve analysis system.

Get in touch with our specialists now!

Visual Guide

Related Products

- Laboratory Test Sieves and Sieving Machines

- Laboratory Vibratory Sieve Shaker Machine Slap Vibrating Sieve

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

People Also Ask

- How are vibratory sieve shakers and standard sieves utilized to analyze the effects of biomass torrefaction? Optimize Grindability

- What is the function of sieving equipment in CuAlMn alloys? Master Pore Size Precision

- What is the primary function of a mechanical sieve shaker for biomass analysis? Optimize Particle Size Distribution

- Why is a precision vibrating sieve shaker essential for metal leaching research? Optimize Your Particle Size Analysis

- What is the primary purpose of using standard sieves? Master Particle Uniformity for High-Quality Catalyst Preparation