At its core, a roller mill is a specialized machine for processing high-viscosity materials. It finds applications across a diverse range of industries, from manufacturing high-performance ceramics and electronic inks to creating smooth cosmetics, paints, pharmaceuticals, and even certain foods. Its primary function is to grind, homogenize, and disperse solid particles within a thick liquid or paste base, ensuring exceptional uniformity.

The true value of a roller mill lies in its ability to apply intense shear force to viscous materials. This makes it the ideal tool for applications where achieving an extremely fine and uniform particle dispersion is critical to the final product's quality, texture, and performance.

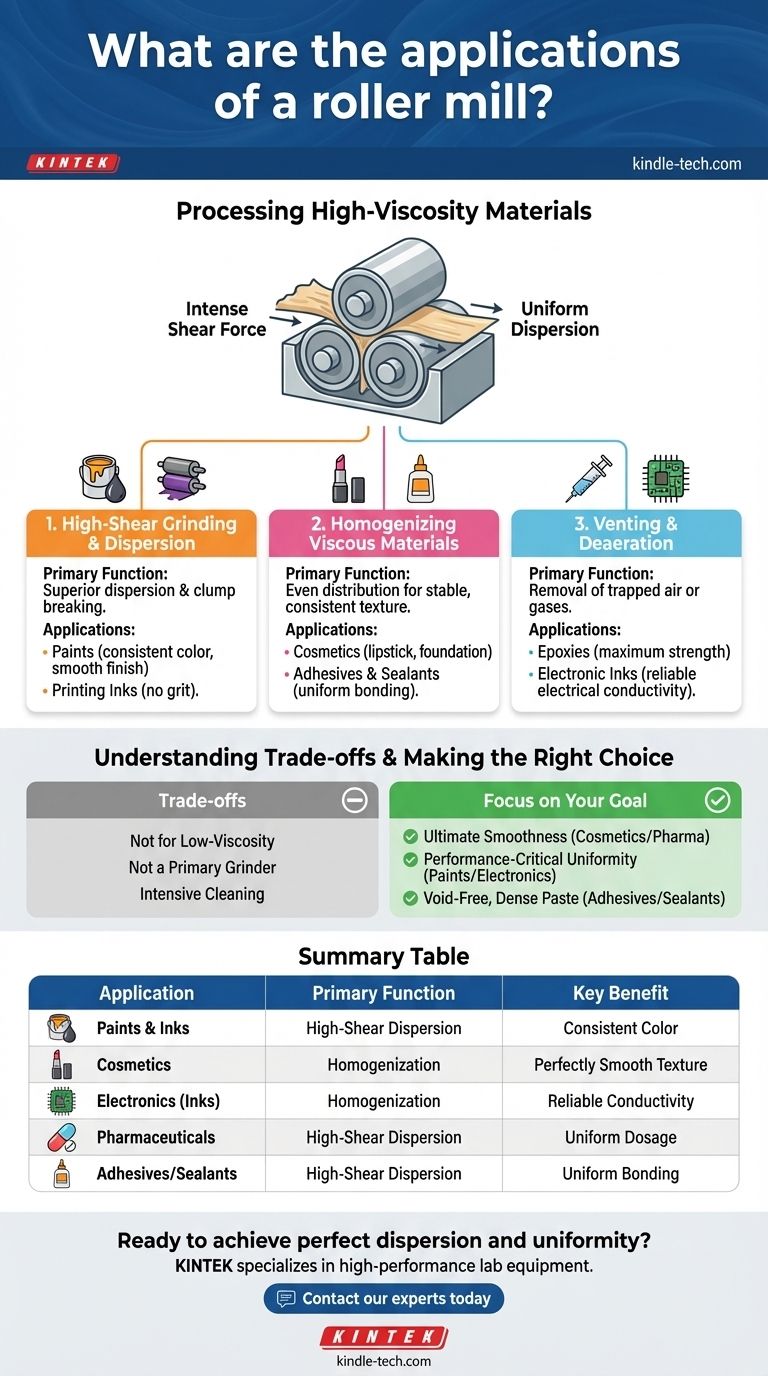

The Core Functions Driving Roller Mill Applications

A roller mill, most commonly a three-roll mill, works by passing material through the gaps (or "nips") between rotating cylinders. Each successive gap is narrower, creating immense shear force that tears apart agglomerates and disperses particles evenly.

High-Shear Grinding and Dispersion

The primary purpose of a roller mill is to achieve a superior level of dispersion. The immense pressure and shear force break down clumps of solid particles.

This is critical in products like paints and printing inks, where undispersed pigment agglomerates would lead to inconsistent color, poor finish, and grit.

Homogenizing Viscous Materials

Homogenization ensures that every component is distributed evenly throughout the mixture, resulting in a stable and consistent final product.

In the cosmetics industry, this process is essential for creating products like lipstick or foundation with a perfectly smooth texture. For adhesives and sealants, it guarantees uniform bonding and curing properties.

Venting and Deaeration

The milling process can also help remove trapped air or gases from a mixture, a process known as venting or deaeration.

This is vital for epoxies and electronic thick film inks, where air bubbles could create weak points or disrupt electrical conductivity, compromising the performance of the final product.

Understanding the Trade-offs

While powerful, a roller mill is a specialized tool, not a universal solution. Understanding its limitations is key to using it effectively.

Not for Low-Viscosity Liquids

Roller mills rely on the material's high viscosity to be drawn into the roller gaps. They are inefficient for thin, watery liquids, which would simply splash off the rollers.

Primarily a Dispersion Tool, Not a Grinder

While a roller mill does reduce particle size, its main strength is breaking apart clumps (de-agglomeration) rather than fracturing primary crystals (true grinding). It perfects a pre-mixed paste.

Intensive Cleaning Requirements

The nature of the machine requires thorough cleaning between batches, especially when changing colors or formulations. This can make it less suitable for applications requiring rapid, frequent product changeovers.

Making the Right Choice for Your Goal

Choosing a roller mill depends entirely on the specific properties required in your final product.

- If your primary focus is ultimate smoothness and texture: A roller mill is indispensable for high-end cosmetics, pharmaceuticals, and certain food products where a gritty feel is unacceptable.

- If your primary focus is performance-critical uniformity: It is the standard for producing high-quality paints, printing inks, and electronic components where consistent dispersion is directly tied to function.

- If your primary focus is creating a void-free, dense paste: The deaeration properties are crucial for adhesives, sealants, and epoxies that require maximum strength and reliability.

Ultimately, a roller mill is the definitive tool when the quality of your viscous product is defined by the fineness of its dispersion.

Summary Table:

| Application | Primary Function | Key Benefit |

|---|---|---|

| Paints & Inks | High-Shear Dispersion | Consistent color, smooth finish, no grit |

| Cosmetics | Homogenization | Perfectly smooth texture (e.g., lipstick) |

| Electronics (Inks) | Dispersion & Deaeration | Reliable electrical conductivity |

| Pharmaceuticals | Grinding & Homogenization | Uniform dosage and efficacy |

| Adhesives/Sealants | Homogenization & Deaeration | Uniform bonding, maximum strength |

Ready to achieve perfect dispersion and uniformity in your viscous products?

KINTEK specializes in high-performance lab equipment, including roller mills, designed to meet the rigorous demands of industries like yours. Whether you are developing paints, cosmetics, pharmaceuticals, or electronic materials, our solutions ensure the fine particle dispersion critical to your product's quality and performance.

Contact our experts today to discuss how a KINTEK roller mill can enhance your production process and deliver superior results for your target customers.

Visual Guide

Related Products

- Laboratory Single Horizontal Jar Mill

- High Energy Vibratory Laboratory Ball Mill Double Tank Type

- Laboratory Planetary Ball Mill Rotating Ball Milling Machine

- High-Energy Omnidirectional Planetary Ball Mill Milling Machine for Laboratory

- High-Energy Omnidirectional Planetary Ball Mill Machine for Laboratory

People Also Ask

- What is the ball mill based on the principle of? Impact and Attrition for Efficient Grinding

- How do stainless steel grinding jars and balls contribute to mechanical alloying? Optimize HEA Powder Synthesis

- Why are silicon nitride or zirconia preferred for milling iodo-vanadate-lead precursors? Ensure High Purity Results

- What are the advantages of polyurethane ball mill jars for silicon nitride? Ensure Purity & Prevent Metal Contamination

- Why are excellent sealing and corrosion resistance required for WC-10Co ball milling? Ensure High-Purity Mixing Results