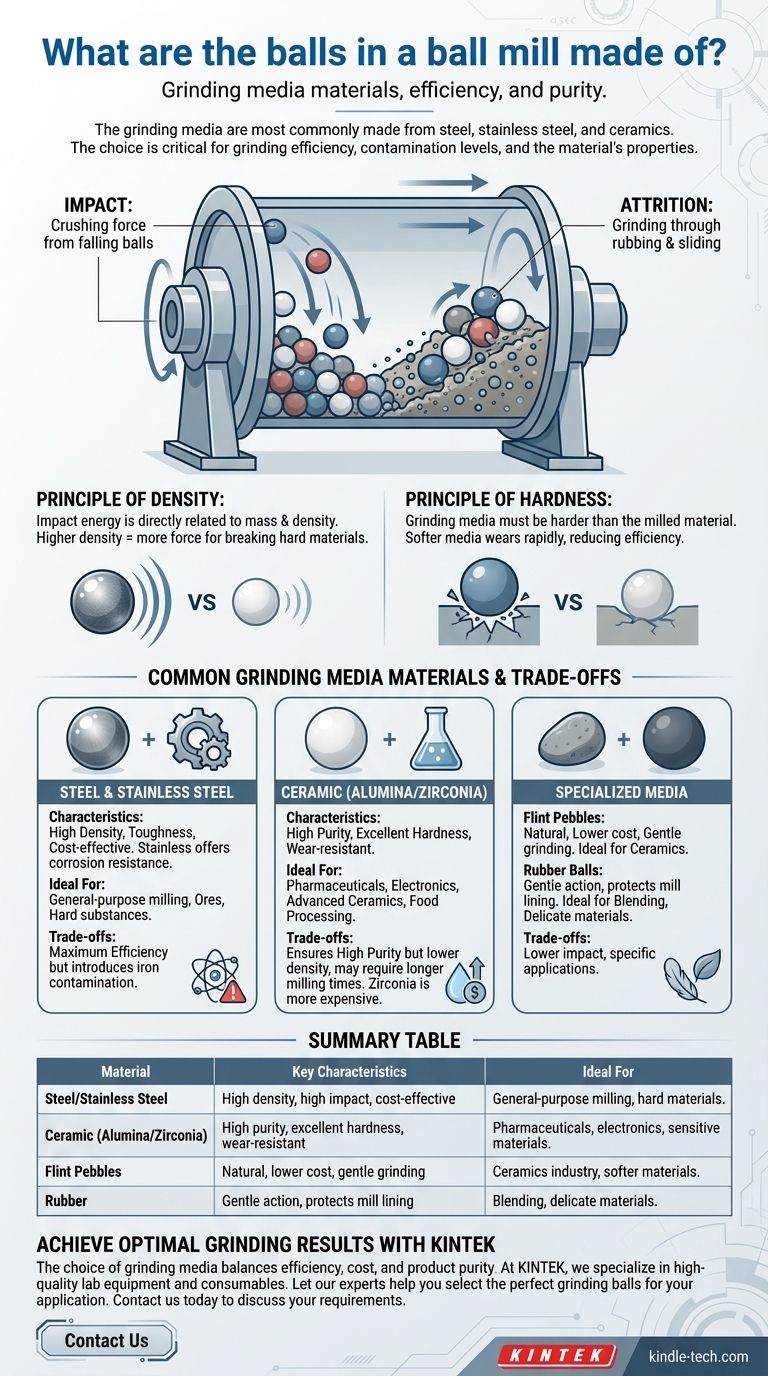

The grinding media in a ball mill are most commonly made from steel, stainless steel, and various types of ceramic. Other specialized materials, such as flint pebbles or even rubber, are also used depending on the specific grinding application and the desired purity of the final product.

The choice of ball material is not arbitrary; it is a critical decision driven by the required grinding efficiency, the acceptable level of contamination, and the properties of the material being processed. The density and hardness of the balls directly determine the outcome of the milling operation.

Why Material Selection is Critical

A ball mill reduces the size of materials through two primary mechanisms: impact and attrition. The material chosen for the grinding media is fundamental to how effectively these forces are applied.

The Role of Impact and Attrition

A ball mill is a rotating cylinder partially filled with the grinding media. As the cylinder rotates, the balls are lifted up the side and then cascade or drop down, creating an impact force that crushes the material.

Simultaneously, the rubbing and sliding of the balls against each other and the material causes attrition, which grinds the particles down to a fine powder.

The Principle of Density

The impact energy of a ball is directly related to its mass and therefore its density. Higher-density media, like steel, deliver significantly more force upon impact.

This makes high-density materials far more effective for breaking down hard, tough feed materials quickly.

The Principle of Hardness

For effective grinding, the grinding media must be substantially harder than the material being milled. If the media is softer, it will wear down rapidly without effectively reducing the particle size of the target material.

Common Grinding Media Materials

The ideal material balances grinding efficiency with the chemical requirements of the final product, primarily concerning contamination.

Steel and Stainless Steel

Steel balls are the industry standard for many applications due to their high density, toughness, and relatively low cost. They provide the high-impact energy needed for rapid size reduction of ores and other hard substances.

Stainless steel offers the same high-density benefits but with the added advantage of corrosion resistance and significantly lower product contamination, making it a preferred choice in many industrial processes.

Ceramic

Ceramic media, such as alumina and zirconia, are used when avoiding metallic contamination is the top priority.

These materials are essential in industries like pharmaceuticals, advanced ceramics, electronics, and food processing, where even trace amounts of iron can ruin a product. While less dense than steel, they offer excellent hardness and wear resistance.

Other Specialized Media

Flint pebbles are a natural, lower-cost alternative to manufactured ceramic balls and have been used for centuries, particularly in the ceramic industry.

Rubber balls are used in niche applications where a much gentler, lower-impact grinding or blending action is required to avoid damaging the material or the mill's internal lining.

Understanding the Trade-offs

Choosing a grinding media always involves balancing performance, cost, and product purity. There is no single "best" material for all situations.

Contamination vs. Efficiency

This is the central trade-off. Steel offers maximum efficiency but will inevitably introduce small amounts of iron contamination as it wears.

Ceramic media ensures high purity but may require longer milling times due to its lower density compared to steel.

Cost Considerations

Carbon steel balls are generally the most cost-effective option for large-scale, general-purpose grinding.

In contrast, high-purity ceramic media, especially zirconia, are significantly more expensive. Their use is justified only when product purity is a non-negotiable requirement.

Wear and Tear

All grinding media wears down over time. This wear not only introduces contamination but also changes the size and efficiency of the media itself. The rate of wear depends on the hardness of both the media and the material being ground.

Making the Right Choice for Your Application

Your final decision should be guided by the primary goal of your milling process.

- If your primary focus is speed and grinding hard materials: High-density steel or stainless steel balls are the standard choice due to their superior impact energy.

- If your primary focus is product purity and avoiding metal contamination: Ceramic media, such as alumina or zirconia, is essential for sensitive applications.

- If your primary focus is low-cost milling of softer materials: Flint pebbles can provide an effective and economical solution, especially in the ceramics industry.

Selecting the correct grinding media is the foundational step toward achieving a consistent and high-quality final product.

Summary Table:

| Material | Key Characteristics | Ideal For |

|---|---|---|

| Steel/Stainless Steel | High density, high impact, cost-effective | General-purpose milling, hard materials |

| Ceramic (Alumina/Zirconia) | High purity, excellent hardness, wear-resistant | Pharmaceuticals, electronics, sensitive materials |

| Flint Pebbles | Natural, lower cost, gentle grinding | Ceramics industry, softer materials |

| Rubber | Gentle action, protects mill lining | Blending, delicate materials |

Achieve optimal grinding results with the right media.

The choice of grinding media is critical to your milling operation's success, balancing efficiency, cost, and product purity. At KINTEK, we specialize in providing high-quality lab equipment and consumables, including a full range of grinding media tailored to your specific laboratory needs.

Let our experts help you select the perfect grinding balls for your application. Contact us today to discuss your requirements and ensure a consistent, high-quality final product.

Visual Guide

Related Products

- Laboratory Planetary Ball Mill Rotating Ball Milling Machine

- High Energy Planetary Ball Mill Milling Machine for Laboratory

- High-Energy Omnidirectional Planetary Ball Mill Milling Machine for Laboratory

- High-Energy Omnidirectional Planetary Ball Mill Machine for Laboratory

- Laboratory Horizontal Planetary Ball Mill Milling Machine

People Also Ask

- What is the critical role of a planetary ball mill in WC-Co preparation? Master High-Energy Mechanical Alloying

- Why is secondary ball milling necessary for LATP? Enhance Sintering Activity & Ionic Conductivity

- What role does a planetary ball mill play in the preparation of nano-scale ceramic fillers? Optimize Solid Electrolytes

- Why are hardened steel grinding balls and jars selected for ODS ferritic steel? Maximize Alloying Efficiency & Purity

- What is the specific processing objective of using a planetary ball mill with 2mm beads for composite cathodes?

- Why do conventional planetary ball mills often fail with PTO and Li3PS4 cathodes? Enhance Your Battery Material Processing

- How does a planetary ball mill contribute to geopolymer synthesis? Unlock Superior Mechanical Activation

- What is the difference between a pulverizer and a ball mill? Choose the Right Grinding Technology