In essence, plastic pyrolysis is a chemical recycling process that uses high temperatures in an oxygen-free environment to break down plastic waste. This thermal decomposition transforms complex plastic polymers into simpler, valuable outputs like synthetic oil, gas, and a solid residue called char, fundamentally changing how we view and manage plastic waste.

The core benefit of pyrolysis is its ability to transform a persistent environmental liability—end-of-life plastic—into a valuable economic asset. It's not just about disposal; it's about resource recovery and creating a pathway for a circular materials economy.

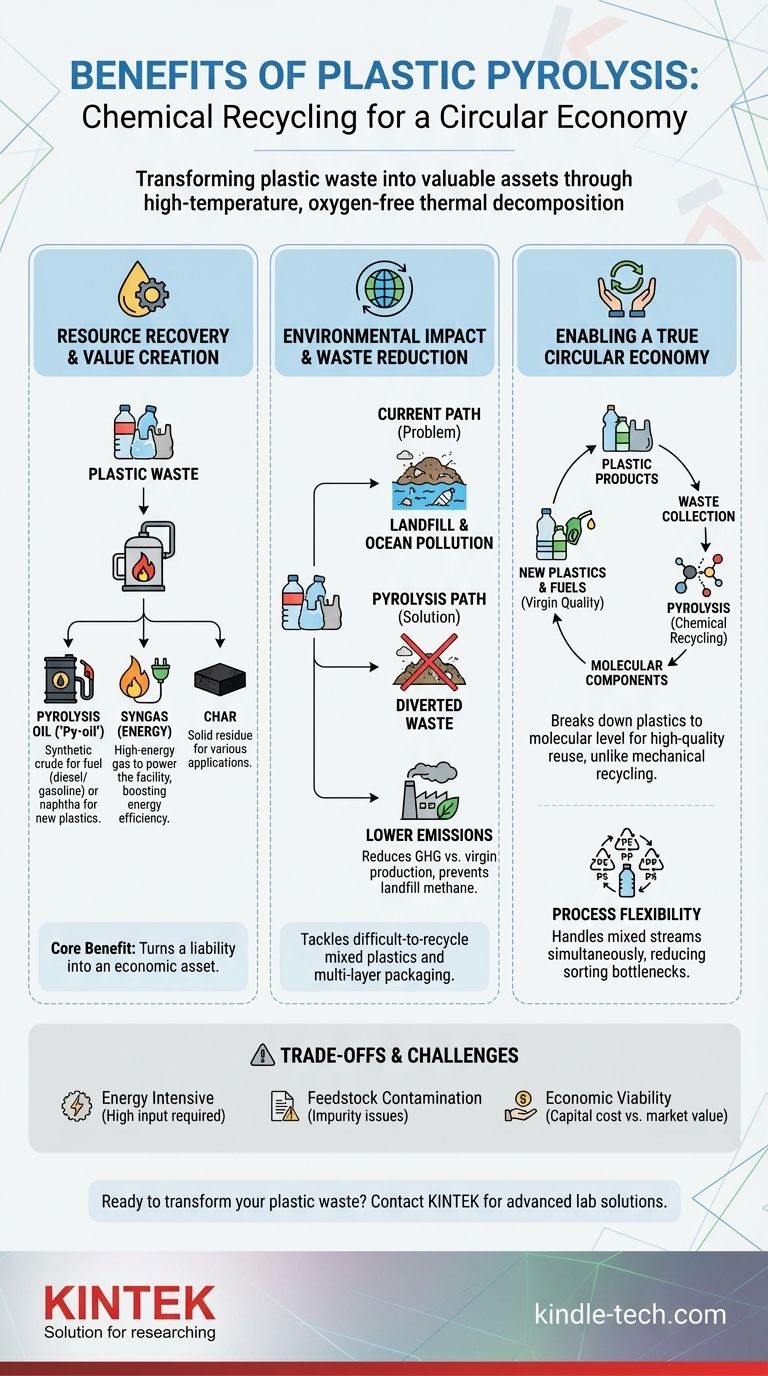

From Waste Stream to Value Stream

Pyrolysis reclaims the chemical and energy value locked inside plastic waste. It offers a solution for plastics that are difficult or impossible to recycle through traditional mechanical methods, which often require clean, sorted, single-polymer streams.

The Primary Output: Pyrolysis Oil

The main product of plastic pyrolysis is a synthetic crude oil, often called pyrolysis oil or "py-oil." This liquid can be refined into various fuels, including diesel and gasoline alternatives.

It can also be processed into naphtha, which serves as a feedstock for creating new, virgin-quality plastics, effectively closing the loop on plastic production.

Recovering Energy with Syngas

The process also generates a mixture of combustible gases known as syngas. This gas has a high energy content and can be captured and used to power the pyrolysis facility itself.

This self-sustaining energy loop significantly improves the overall energy efficiency of the operation, reducing its reliance on external power sources.

Reducing Landfill and Ocean-Bound Waste

A primary driver for pyrolysis is the drastic reduction of plastic waste sent to landfills. By converting this waste into useful products, pyrolysis directly tackles a major source of land and water pollution.

This is especially critical for mixed or contaminated plastic films and multi-layer packaging that are typically rejected by conventional recycling centers.

The Environmental and Economic Equation

Beyond simple waste management, pyrolysis offers broader benefits that align with goals for sustainability and resource independence. It reframes plastic from single-use trash into a durable, recoverable resource.

A Pathway to Lower Emissions

When compared to producing fuels and plastics from virgin fossil fuels, using pyrolysis oil can lead to a reduction in greenhouse gas emissions.

Furthermore, it prevents the emissions that would otherwise occur from landfilling (methane) or incinerating plastic waste, offering a more environmentally sound alternative.

Enabling a True Circular Economy

Pyrolysis is a cornerstone of chemical recycling. Unlike mechanical recycling, which can degrade plastic quality over time, pyrolysis breaks plastics down to their basic molecular components.

These components can then be used to create new products with no loss of quality, supporting the vision of a circular economy where materials are continuously reused rather than discarded.

Flexibility in Processing Diverse Plastics

One of the most significant operational advantages of pyrolysis is its flexibility. Modern pyrolysis plants can process a wide range of plastic types simultaneously, including polyethylene (PE), polypropylene (PP), and polystyrene (PS).

This ability to handle mixed plastic streams dramatically reduces the need for intensive sorting, a major bottleneck and cost driver in traditional recycling.

Understanding the Trade-offs and Challenges

While promising, pyrolysis is not a perfect solution and comes with its own set of technical and economic hurdles. An objective assessment requires acknowledging these limitations.

Energy Input vs. Energy Output

The pyrolysis process is energy-intensive, requiring high temperatures to break down plastic polymers. The net energy balance—the energy produced minus the energy consumed—is a critical factor for both environmental impact and economic viability.

Feedstock Contamination Issues

Real-world plastic waste is rarely pure. Contaminants like food residue, paper, metal, and certain plastic additives (like PVC, which releases harmful chlorine) can reduce the quality of the pyrolysis oil and require additional pre-processing or post-processing steps.

Scalability and Economic Viability

Building and operating advanced pyrolysis facilities requires significant capital investment. The final products must compete in the market with historically low-cost fossil fuels and virgin plastics, making economic feasibility a constant challenge.

Making the Right Choice for Your Goal

Pyrolysis is a powerful tool, but its application depends on the specific problem you are trying to solve.

- If your primary focus is waste volume reduction: Pyrolysis is one of the most effective technologies for diverting a wide range of non-recyclable plastics from landfills.

- If your primary focus is energy production: The technology offers a viable path to creating alternative liquid fuels from a readily available domestic feedstock.

- If your primary focus is building a circular economy: Pyrolysis is a key enabler for turning end-of-life plastics back into high-quality raw materials for new products.

Ultimately, plastic pyrolysis represents a critical technological step toward a more sustainable and resourceful materials future.

Summary Table:

| Benefit | Key Outcome |

|---|---|

| Resource Recovery | Converts plastic waste into pyrolysis oil, syngas, and char. |

| Waste Reduction | Diverts difficult-to-recycle plastics from landfills and oceans. |

| Circular Economy | Creates feedstock for new plastics and fuels, closing the material loop. |

| Energy Efficiency | Syngas can power the process, reducing external energy needs. |

| Emission Reduction | Lowers greenhouse gas emissions vs. virgin fossil fuel production. |

Ready to transform your plastic waste into valuable resources?

KINTEK specializes in advanced lab equipment and consumables for pyrolysis research and development. Whether you're optimizing processes, analyzing outputs, or scaling up your operations, our solutions help you achieve greater efficiency and sustainability.

Contact our experts today to discuss how KINTEK can support your journey toward a circular economy.

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

- Vacuum Dental Porcelain Sintering Furnace

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

People Also Ask

- What is the efficiency of plastic pyrolysis? A Deep Dive into Mass Yield, Energy Balance, and Economic Viability

- Why is a thermostatic shaker required for SSF of rice husk solids? Maximize Your Ethanol Yield with Precision Agitation

- What is the composition of plastic pyrolysis product? A Breakdown of Oil, Gas, and Char Outputs

- What is the correct shutdown and disassembly procedure after an experiment? Ensure Safety and Protect Your Equipment

- What are 3 renewable alternative energy sources? Solar, Wind, and Hydropower Explained

- Why is energy consumption a critical consideration for ULT freezers? Key to Balancing Performance, Cost, and Sustainability

- What is the range of sputtering? Achieve High-Quality Thin Films for Any Application

- Why is a magnetic stirrer necessary during the preparation of graphene oxide? Ensure Safety and Uniform Oxidation