The primary benefit of plastic pyrolysis is its capacity to chemically break down plastic waste, which is often non-recyclable, and convert it into valuable resources. This advanced recycling process transforms a significant environmental liability into tangible assets, such as synthetic oil, gas, and solid carbon, effectively creating a new pathway for materials that would otherwise end up in landfills or oceans.

Plastic pyrolysis is not merely a waste disposal method; it is a resource recovery technology. It addresses the core problem of plastic pollution by creating a circular loop, turning end-of-life plastics back into the raw materials for fuel and new manufacturing.

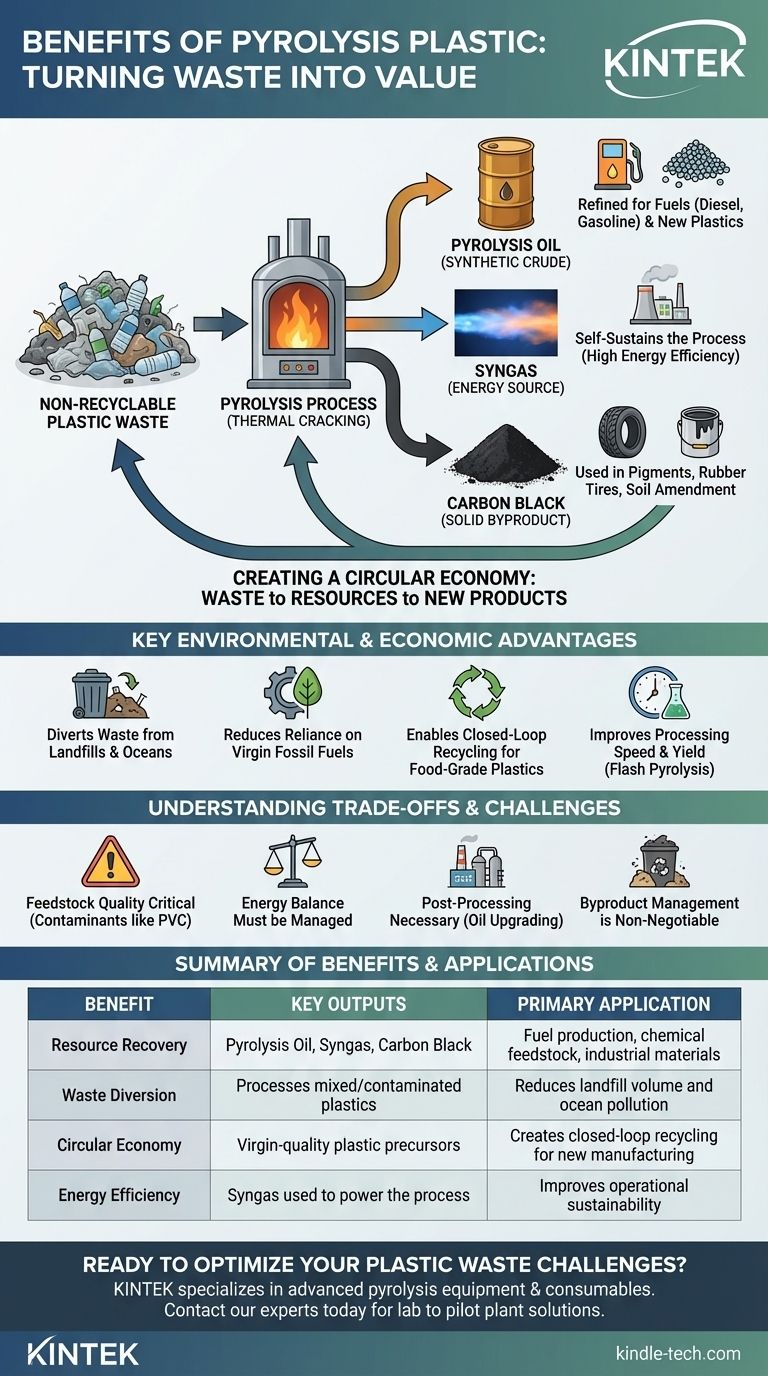

How Plastic Pyrolysis Creates Value

The benefits of pyrolysis stem from its ability to deconstruct complex plastic polymers in an oxygen-free environment. This process, known as thermal cracking, results in several useful outputs.

Pyrolysis Oil: A Synthetic Crude

The main liquid product is a synthetic oil, often called pyrolysis oil or "pyo-oil." This substance is chemically similar to conventional crude oil.

It can be refined and upgraded into diesel, gasoline, or other liquid fuels, providing a direct alternative to fossil fuels. It can also serve as a chemical feedstock to produce new, virgin-quality plastics.

Syngas: An Internal Energy Source

The process also generates a non-condensable gas, commonly known as syngas. This gas is rich in energy.

A key advantage of modern pyrolysis plants is their ability to capture this syngas and use it to power the very furnaces that sustain the pyrolysis reaction. This creates a self-sustaining energy loop, significantly improving the overall energy efficiency of the operation.

Carbon Black: A Solid Byproduct

The solid residue left after pyrolysis is a carbon-rich material known as carbon black or char.

Instead of being waste, this byproduct has industrial value. It can be used as a pigment in paints and inks, a reinforcing agent in rubber tires, or as a soil amendment. This recovery turns what would be a final waste product into another revenue stream.

Key Environmental and Economic Advantages

By transforming waste into these valuable streams, pyrolysis offers a compelling set of benefits that address both environmental regulations and economic incentives.

Diverting Waste from Landfills

Pyrolysis can process a wide range of plastics, including mixed and contaminated types that traditional mechanical recycling cannot handle. This flexibility makes it a powerful tool for diverting massive volumes of plastic from overflowing landfills and fragile marine ecosystems.

Reducing Reliance on Virgin Resources

By producing synthetic oil and recovering carbon, pyrolysis reduces the need to extract virgin fossil fuels and manufacture new materials from scratch. This directly contributes to resource conservation and a more resilient supply chain.

Enabling a Circular Economy

The most significant long-term benefit is the potential for true circularity. Turning old plastic packaging back into the chemical building blocks for new, food-grade plastic is the "holy grail" of recycling, and pyrolysis makes this chemically possible.

Improving Processing Speed and Yield

Modern methods like flash pyrolysis operate at very high temperatures for short durations. This approach increases the yield of valuable liquid oil, processes waste faster, and can handle larger volumes, making the technology more commercially viable.

Understanding the Trade-offs and Challenges

As a technical advisor, it's crucial to acknowledge that pyrolysis is not a perfect solution. Understanding its limitations is key to successful implementation.

Feedstock Quality is Critical

The purity of the plastic waste feedstock matters. Contaminants like PVC can release chlorine, leading to the formation of corrosive acids that damage equipment and complicate the refining process for the final oil.

Energy Balance Must Be Managed

While the process can use its own syngas for power, starting and maintaining the high temperatures required for pyrolysis demands a significant initial energy input. A positive net energy balance is essential for the process to be considered truly sustainable.

Post-Processing is Necessary

Pyrolysis oil is not a "drop-in" fuel. It is a raw, synthetic crude that requires filtering, stabilization, and upgrading in a refinery before it can be used as a commercial fuel or chemical feedstock. This adds cost and complexity.

Byproduct Management is Non-Negotiable

While the carbon black char has value, a market must exist for it to be considered a product rather than a waste. Likewise, any wastewater generated from moisture in the feedstock must be treated responsibly.

Making the Right Choice for Your Goal

To apply this technology effectively, you must align its capabilities with your primary objective.

- If your primary focus is waste management: Pyrolysis is an excellent solution for reducing landfill volume by processing mixed and difficult-to-recycle plastics.

- If your primary focus is energy production: The technology provides a consistent source of synthetic crude oil, but you must account for the necessary investment in post-processing and refining infrastructure.

- If your primary focus is creating a circular economy: Plastic-to-plastic chemical recycling via pyrolysis is one of the most promising pathways to produce virgin-quality polymers from post-consumer waste.

Ultimately, plastic pyrolysis serves as a critical technological bridge, turning the linear path of plastic waste into a circular system of resource recovery.

Summary Table:

| Benefit | Key Outputs | Primary Application |

|---|---|---|

| Resource Recovery | Pyrolysis Oil, Syngas, Carbon Black | Fuel production, chemical feedstock, industrial materials |

| Waste Diversion | Processes mixed/contaminated plastics | Reduces landfill volume and ocean pollution |

| Circular Economy | Virgin-quality plastic precursors | Creates closed-loop recycling for new manufacturing |

| Energy Efficiency | Syngas used to power the process | Improves operational sustainability and cost-effectiveness |

Ready to turn your plastic waste challenges into a profitable resource recovery system? KINTEK specializes in advanced pyrolysis equipment and consumables for laboratories and pilot plants. Whether your goal is waste management, energy production, or pioneering circular economy solutions, our expertise can help you optimize your process from feedstock to final product. Contact our experts today to discuss how we can support your specific pyrolysis application and drive your sustainability goals forward.

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- Laboratory Rapid Thermal Processing (RTP) Quartz Tube Furnace

- Mini SS High Pressure Autoclave Reactor for Laboratory Use

People Also Ask

- What are the reactions involved in pyrolysis of biomass? Unlock the Chemistry for Tailored Bio-Products

- What are the products of pyrolysis of biomass? Unlock Bio-Char, Bio-Oil, and Syngas

- What is the process of biomass fast pyrolysis? Turn Biomass into Bio-Oil in Seconds

- How is energy converted into biomass? Harnessing Nature's Solar Power for Renewable Energy

- What are the different types of pyrolysis machines? Choose the Right System for Your Output