The byproducts of plastic pyrolysis are a diverse mixture of solid, liquid, and gaseous materials. The process does not destroy the plastic but thermally decomposes it in the absence of oxygen, converting it into a solid char residue, a liquid pyrolysis oil, and a stream of non-condensable gases. These gases include hydrogen, methane, ethylene, carbon monoxide, and carbon dioxide.

Pyrolysis should be viewed not as a disposal method, but as a chemical conversion process. The specific byproducts and their economic value are not fixed; they are highly dependent on the type of plastic feedstock and the precise conditions under which the pyrolysis is performed.

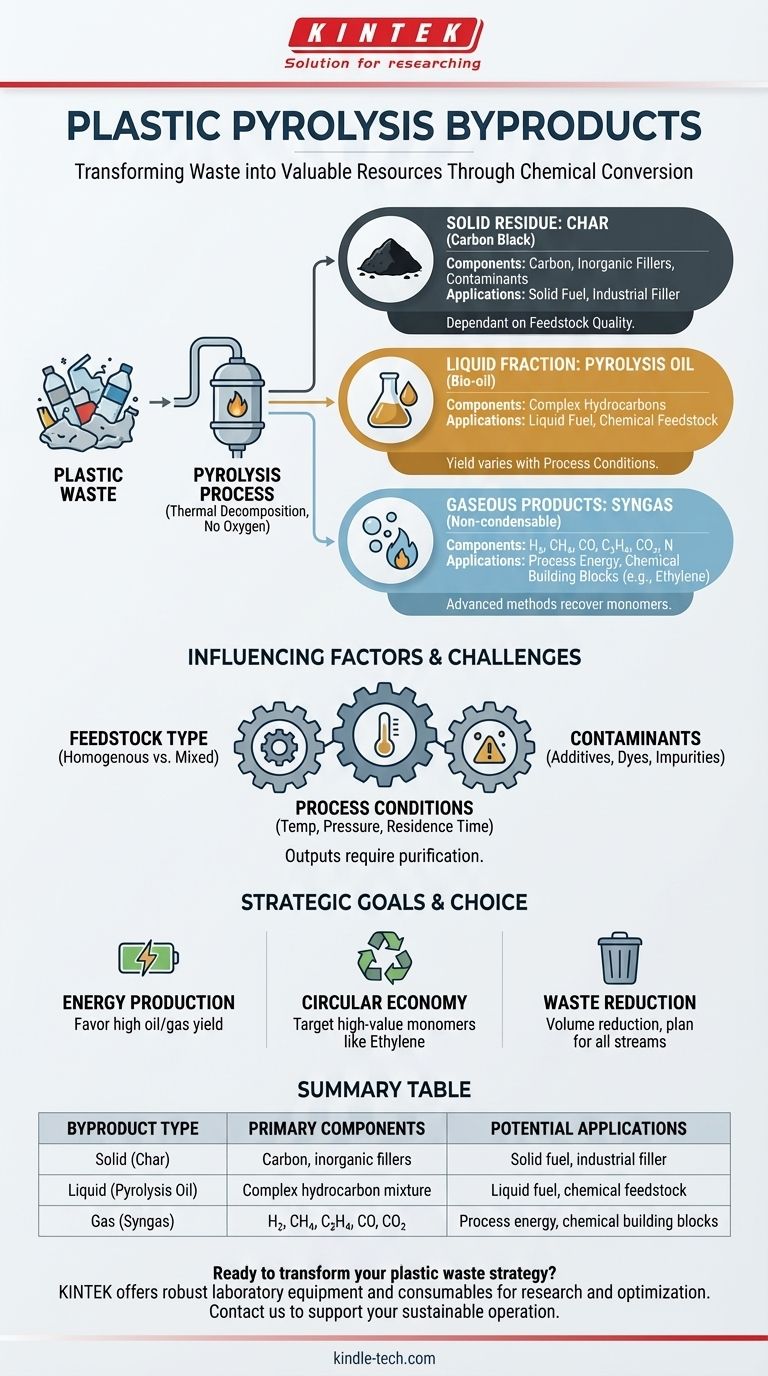

Deconstructing the Outputs: Solid, Liquid, and Gas

Plastic pyrolysis breaks down long polymer chains into smaller, more manageable molecules. These resulting substances fall into one of three distinct physical states, each with its own characteristics and potential applications.

The Solid Residue: Char

The primary solid byproduct is a carbon-rich material often referred to as char or carbon black.

This residue consists of the non-volatile components of the original plastic waste, including carbon and any inorganic fillers, additives, or contaminants. Its quality determines its potential use as a solid fuel or an industrial filler.

The Liquid Fraction: Pyrolysis Oil

During the process, hot pyrolysis gas is cooled, causing a significant portion to condense into a liquid. This is commonly known as pyrolysis oil or bio-oil.

This oil is a complex blend of various hydrocarbon compounds. It can be refined for use as a liquid fuel or, more importantly, serve as a chemical feedstock to synthesize new chemicals and materials.

The Gaseous Products: Syngas and Chemical Building Blocks

The gases that do not condense during cooling are known as non-condensable gases or syngas. This mixture contains a range of valuable and inert components.

The primary constituents include energy-rich gases like hydrogen (H2), methane (CH4), and carbon monoxide (CO). These can be combusted on-site to provide the energy needed to power the pyrolysis process itself.

Critically, the gas stream can also contain valuable chemical building blocks. For instance, some advanced methods like cold plasma pyrolysis are optimized to recover ethylene (C2H4), the fundamental monomer used to create many new plastics.

Finally, the gas also contains inert or less valuable byproducts like carbon dioxide (CO2) and nitrogen (N), which must be managed.

Understanding the Trade-offs and Critical Variables

The promise of turning waste plastic into valuable resources is compelling, but the reality is complex. The output is not standardized and is sensitive to several factors that can introduce significant challenges.

The Influence of Feedstock

The type of plastic waste used as feedstock has the single greatest impact on the byproducts. A clean, homogenous stream of a single plastic type will produce a more consistent and valuable output than mixed, contaminated municipal plastic waste.

The Impact of Process Conditions

Variables like temperature, pressure, and residence time inside the reactor fundamentally alter the product distribution. Higher temperatures tend to favor gas production, while lower temperatures and faster processing can yield more liquid oil.

Specialized techniques, such as cold plasma pyrolysis, use different energy sources to break down the plastic, which can be optimized to produce specific high-value chemicals like ethylene rather than a generic fuel gas.

The Challenge of Contaminants

The pyrolysis oil, gas, and char are rarely pure enough for direct use. They often contain contaminants originating from the plastic additives, dyes, and other materials mixed in with the waste. These outputs almost always require significant and costly purification before they can be sold or used as a feedstock for further chemical processes.

Making the Right Choice for Your Goal

The "best" pyrolysis outcome is defined entirely by your strategic objective. Understanding your goal allows you to evaluate which process conditions and feedstock are most appropriate for your needs.

- If your primary focus is energy production: You should favor conditions that maximize the yield of combustible pyrolysis oil and energy-rich gases like methane and hydrogen.

- If your primary focus is a circular economy: You should investigate advanced pyrolysis methods engineered to recover high-value chemical monomers, such as ethylene, which can be used to create new, virgin-quality plastics.

- If your primary focus is waste volume reduction: Any pyrolysis process will drastically reduce the volume of plastic waste, but you must have a clear and economically viable plan to manage the resulting solid, liquid, and gaseous streams.

Understanding the specific composition of pyrolysis byproducts is the critical first step in evaluating its true potential as a sustainable solution for plastic waste.

Summary Table:

| Byproduct Type | Primary Components | Potential Applications |

|---|---|---|

| Solid (Char) | Carbon, inorganic fillers | Solid fuel, industrial filler |

| Liquid (Pyrolysis Oil) | Complex hydrocarbon mixture | Liquid fuel, chemical feedstock |

| Gas (Syngas) | Hydrogen (H₂), Methane (CH₄), Ethylene (C₂H₄), CO, CO₂ | Process energy, chemical building blocks |

Ready to transform your plastic waste management strategy?

The byproducts of pyrolysis are not just waste—they are potential revenue streams. KINTEK specializes in providing robust laboratory equipment and consumables to help you research, develop, and optimize your pyrolysis processes. Whether you're focusing on energy recovery or chemical monomer recycling, our solutions can help you achieve precise control and analyze your outputs effectively.

Contact us today to discuss how our expertise can support your specific goals in creating a more sustainable and profitable operation. Get in touch via our contact form and let's build your circular economy solution together.

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- High Pressure Laboratory Autoclave Reactor for Hydrothermal Synthesis

- Mini SS High Pressure Autoclave Reactor for Laboratory Use

- Stainless High Pressure Autoclave Reactor Laboratory Pressure Reactor

People Also Ask

- What is the brazing process in short note? Master the Key Parameters for Strong Metal Joints

- What is a vacuum heat treatment furnace? The Ultimate Guide to Controlled Atmosphere Processing

- How do high-precision temperature control industrial furnaces affect Alloy 718? Achieve Superior Material Integrity

- What is low temperature vacuum? A Guide to Precision, Oxide-Free Thermal Processing

- What materials are used in calcination? Unlock the Power of Thermal Decomposition

- What's the difference between brazing and welding aluminum? Choose the Right Joining Method for Your Project

- What is the difference between tempering and sintering? A Guide to Choosing the Right Thermal Process

- What are the advantages of a vacuum drying oven for nZVI? Preserve Chemical Reactivity & Prevent Oxidation