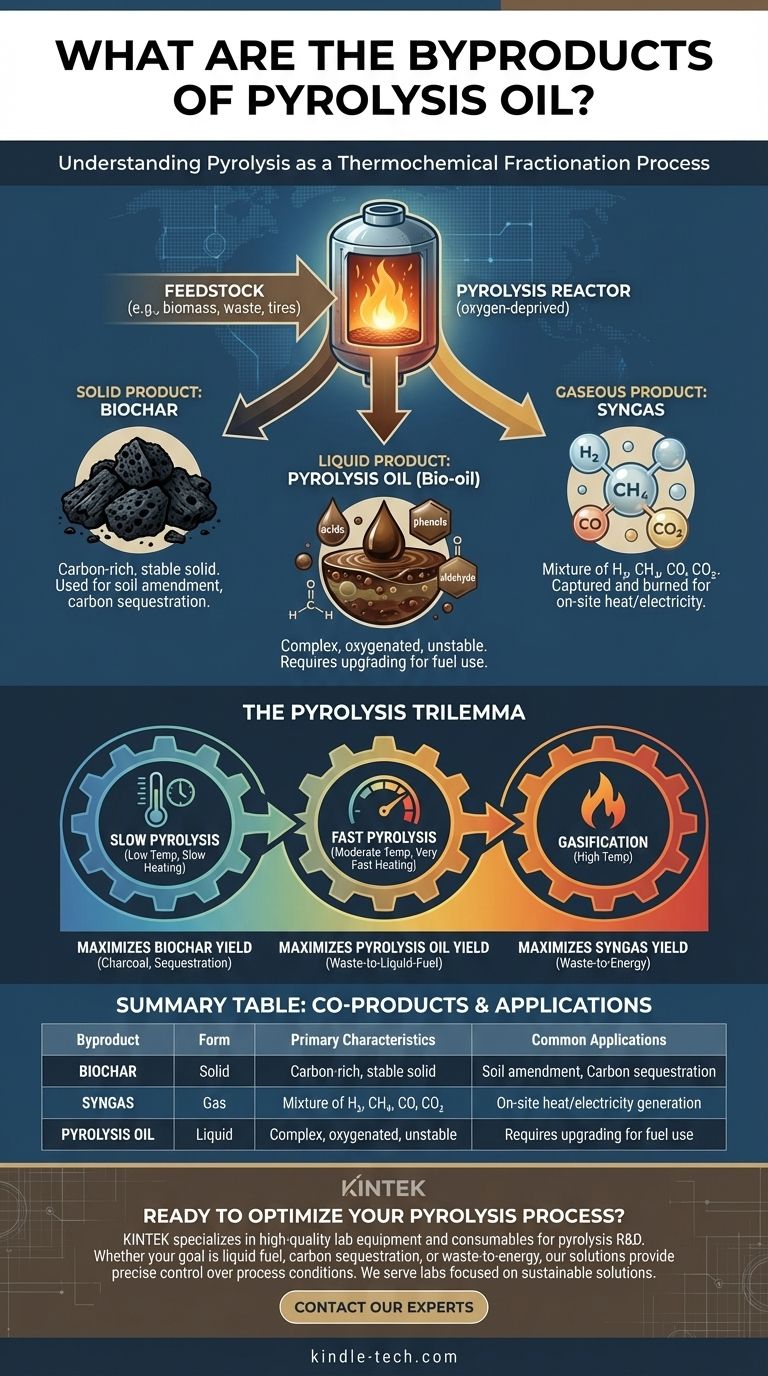

In short, the primary byproducts of the pyrolysis process, which produces pyrolysis oil, are a solid carbonaceous material called biochar and a mixture of non-condensable gases often referred to as syngas. The process essentially separates a feedstock into solid, liquid, and gaseous components.

Understanding pyrolysis requires seeing it not just as an oil-production method, but as a thermochemical fractionation process. The "byproducts" are often co-products with their own distinct value and challenges, and their yields can be tuned based on specific goals.

The Three Core Outputs of Pyrolysis

Pyrolysis is the thermal decomposition of materials at elevated temperatures in an oxygen-deprived environment. This process doesn't burn the material; it breaks it down into three distinct product streams.

Solid Product: Biochar

Biochar is the stable, carbon-rich solid that remains after the volatile components have been driven off. It is essentially a form of charcoal.

The properties and value of biochar depend heavily on the original feedstock and the pyrolysis temperature. Its primary applications include use as a soil amendment to improve fertility and water retention, or as a method for long-term carbon sequestration.

Gaseous Product: Syngas

The process releases a variety of non-condensable gases, collectively known as synthesis gas or syngas.

This gas is a mixture of combustible and non-combustible components, including **hydrogen (H₂), methane (CH₄), carbon monoxide (CO), and carbon dioxide (CO₂) **. In many pyrolysis facilities, this gas stream is not treated as waste; it is captured and burned on-site to provide the heat required to sustain the pyrolysis reaction, improving the overall energy efficiency of the system.

The Liquid Product: Pyrolysis Oil (Bio-oil)

While the question asks for byproducts, understanding the primary liquid product is crucial for context. Pyrolysis oil (or bio-oil) is not a simple oil like petroleum crude.

It is a complex, dark brown liquid emulsion containing hundreds of different oxygenated organic compounds, along with significant amounts of water. This composition, which includes acids, phenols, and aldehydes, makes it inherently unstable, corrosive, and gives it a lower energy density than conventional fossil fuels.

Understanding the Trade-offs

Viewing biochar and syngas merely as "byproducts" can be misleading. The relative output of solid, liquid, and gas is a direct result of the process conditions, which are tuned to meet specific goals.

The "Pyrolysis Trilemma"

There is an inherent trade-off between the three output streams, governed primarily by temperature and heating rate.

- Slow Pyrolysis (Low temp, slow heating): This process maximizes the yield of the solid product, biochar. It is the preferred method for producing charcoal or for carbon sequestration applications.

- Fast Pyrolysis (Moderate temp, very fast heating): This process is optimized to produce the highest possible yield of the liquid product, pyrolysis oil. This is the focus for most "waste-to-liquid-fuel" operations.

- Gasification (High temp): At very high temperatures, the process favors breaking down molecules completely, maximizing the yield of syngas.

The Challenge of Product Quality

A significant challenge in pyrolysis is the variable and often low quality of the initial products. The pyrolysis oil is acidic and requires significant upgrading (e.g., hydrotreating) to be used as a drop-in fuel.

Likewise, the composition of the biochar and syngas is highly dependent on the inconsistency of the input feedstock, whether it's biomass, plastic waste, or tires. This variability complicates efforts to create a standardized, high-value output.

Optimizing Pyrolysis for Your Goal

The right approach depends entirely on which product stream you value most.

- If your primary focus is liquid fuel production: You will use fast pyrolysis to maximize oil yield, but must plan for the significant cost and complexity of upgrading the oil.

- If your primary focus is carbon sequestration: You will use slow pyrolysis to maximize the production of stable, carbon-rich biochar for soil application.

- If your primary focus is waste-to-energy: You will likely use the syngas to power the process and may burn the oil and char for heat or electricity, prioritizing energy self-sufficiency over product refinement.

Ultimately, mastering pyrolysis is about controlling the process to intentionally fractionate a feedstock into the most valuable set of co-products for your specific objective.

Summary Table:

| Byproduct | Form | Primary Characteristics | Common Applications |

|---|---|---|---|

| Biochar | Solid | Carbon-rich, stable solid | Soil amendment, carbon sequestration |

| Syngas | Gas | Mixture of H₂, CH₄, CO, CO₂ | On-site heat/electricity generation |

| Pyrolysis Oil | Liquid | Complex, oxygenated, unstable | Requires upgrading for fuel use |

Ready to optimize your pyrolysis process and maximize the value of your co-products?

At KINTEK, we specialize in providing high-quality lab equipment and consumables for pyrolysis research and development. Whether your goal is liquid fuel production, carbon sequestration, or waste-to-energy conversion, our solutions can help you achieve precise control over your process conditions.

We serve laboratories and researchers focused on developing sustainable energy and material solutions. Let us help you select the right equipment to efficiently produce and analyze biochar, syngas, and pyrolysis oil.

Contact our experts today to discuss your specific pyrolysis application and discover how KINTEK can support your innovation.

Visual Guide

Related Products

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Heating Pyrolysis Plant

- High Purity Zinc Foil for Battery Lab Applications

- Custom PTFE Teflon Parts Manufacturer for PTFE Buchner Funnel and Triangular Funnel

- Custom PTFE Teflon Parts Manufacturer for PTFE Mesh F4 Sieve

- Glassy Carbon Sheet RVC for Electrochemical Experiments

People Also Ask

- What are the zones in rotary kiln in cement production? Master the Core Process for High-Quality Clinker

- What are the equipment for pyrolysis laboratory? Choosing the Right Reactor for Your Research

- How are composites processed using sintering? Engineered Material Solutions Through Advanced Thermal Bonding

- How does a rotary extractor work? Master Continuous High-Volume Solid Processing

- What is the drying zone in a rotary kiln? Boost Efficiency with Modern Drying Solutions