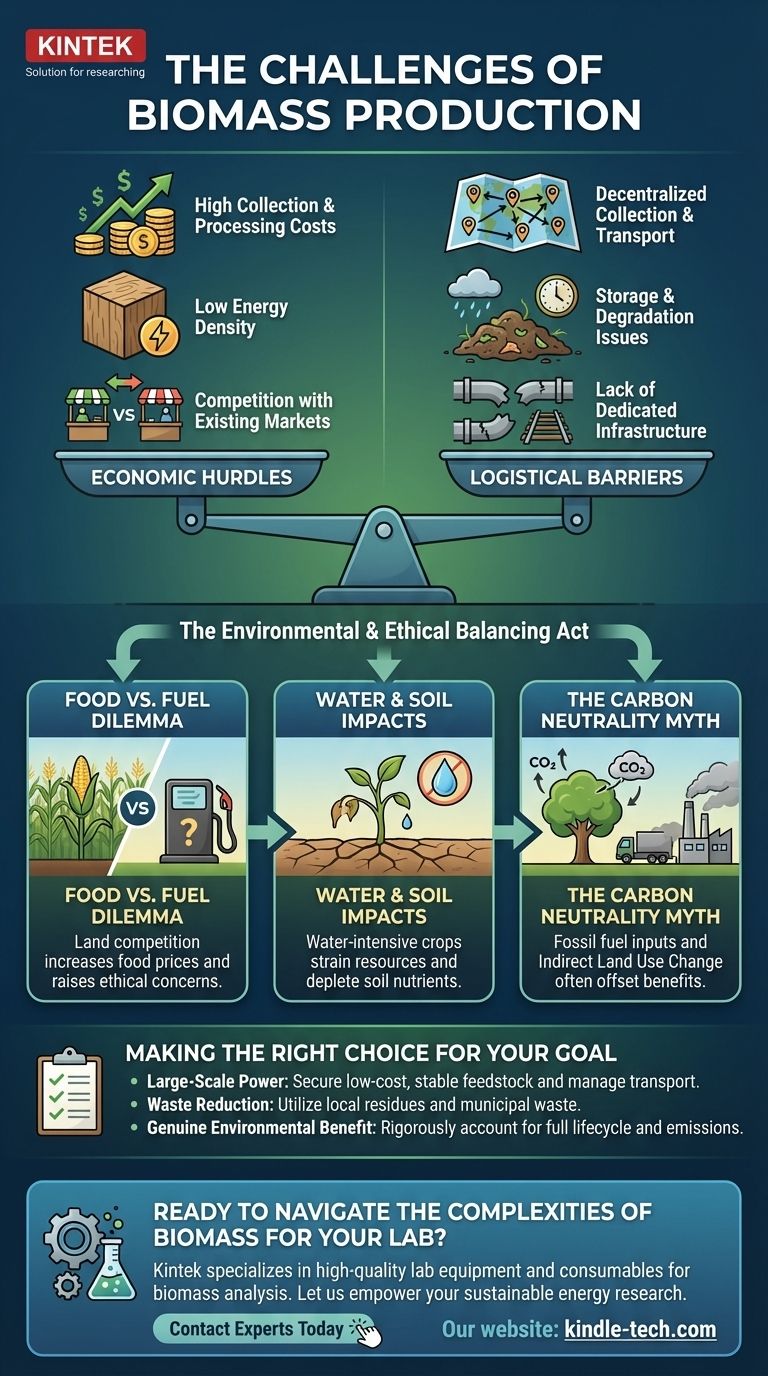

At its core, producing biomass for energy is challenged by a combination of high costs, significant logistical complexity, and competition for essential resources like land and water. These factors create a difficult economic and environmental balancing act that often limits its scalability compared to other energy sources.

The central challenge is not one single factor, but the interconnected nature of biomass economics, logistics, and sustainability. A decision made to solve one problem, such as lowering cost, often creates a new problem in another area, like environmental impact.

The Economic Hurdles of Biomass

The financial viability of biomass is often the first and most significant barrier to adoption. Unlike established fossil fuels, biomass faces an uphill battle to compete on price and efficiency.

High Collection and Processing Costs

Biomass feedstock—the raw organic material—is rarely ready to use. It must be collected from wide, dispersed areas, transported, and then often dried, chopped, or densified into pellets. Each of these steps adds significant operational cost.

Low Energy Density

A key economic driver is energy density. Biomass is bulky and contains less energy per unit of weight or volume compared to coal or natural gas. This means you must transport and process a much larger physical amount of material to generate the same amount of energy, making logistics disproportionately expensive.

Competition with Existing Markets

Biomass materials, such as wood, corn, or agricultural residues, often already have value in other markets like construction, paper production, or animal feed. Energy producers must compete with these established industries, which can drive up the price of feedstock and make it volatile.

Logistical and Infrastructural Barriers

Even with favorable economics, the physical challenge of moving and managing biomass at scale is immense. The world's energy infrastructure was built for dense, easily transportable fuels.

The Collection and Transportation Problem

Biomass sources are typically decentralized. Collecting crop residues from thousands of acres or forestry waste from remote areas requires a massive, coordinated transportation network. This "first mile" collection is often the most inefficient and costly part of the entire supply chain.

Storage and Degradation

Unlike coal, which can be stored for long periods, raw biomass is susceptible to rot and decomposition. It must be stored in controlled conditions, often after being dried or processed into more stable forms like pellets. This adds another layer of infrastructure and cost.

Lack of Dedicated Infrastructure

The global energy system has pipelines, supertankers, and railways designed for oil, gas, and coal. A comparable, dedicated infrastructure for large-scale biomass transport does not exist, forcing reliance on more expensive and less efficient general-purpose road and rail transport.

Understanding the Trade-offs

The promise of "green" energy from biomass is complicated by a series of environmental and ethical trade-offs that cannot be ignored.

The "Food vs. Fuel" Dilemma

Using arable land to grow dedicated energy crops (like corn for ethanol or switchgrass) puts biomass production in direct competition with food production. This can increase food prices and raise significant ethical concerns about resource allocation, especially in a world with growing populations.

Water and Soil Impacts

Many energy crops are water-intensive, placing a strain on local water resources, particularly in arid regions. Furthermore, large-scale monoculture farming of energy crops can deplete soil nutrients and reduce biodiversity if not managed with sustainable agricultural practices.

The Myth of Carbon Neutrality

Biomass is often called carbon neutral because the carbon released when it's burned was previously absorbed from the atmosphere by the plant. However, this simple equation ignores the fossil fuels used in fertilizers, harvesting, processing, and transportation.

Most importantly, it ignores Indirect Land Use Change (ILUC). If a forest is cleared to grow energy crops, the massive amount of carbon stored in that forest's soil and trees is released, potentially creating a "carbon debt" that takes decades of biomass energy production to repay.

Making the Right Choice for Your Goal

Evaluating the viability of biomass requires a clear understanding of your specific objective, as its suitability is highly context-dependent.

- If your primary focus is large-scale, centralized power: The biggest challenge will be securing a low-cost, stable feedstock supply and managing the immense logistical costs of transportation.

- If your primary focus is waste reduction and distributed energy: Using local agricultural residues, forestry waste, or municipal solid waste is often the most economically and environmentally sound approach.

- If your primary focus is genuine environmental benefit: You must rigorously account for the full lifecycle, including land-use change, water impact, and transportation emissions, to ensure the project delivers a true net-positive outcome.

Ultimately, understanding these complex challenges is the first step toward developing responsible and effective biomass energy solutions.

Summary Table:

| Challenge Category | Key Issues |

|---|---|

| Economic Hurdles | High collection/processing costs, low energy density, competition with existing markets |

| Logistical Barriers | Decentralized collection, storage degradation, lack of dedicated infrastructure |

| Sustainability Trade-offs | Food vs. fuel dilemma, water/soil impacts, myth of carbon neutrality |

Ready to Navigate the Complexities of Biomass for Your Lab?

Biomass research and development requires precise, reliable equipment to ensure accurate data and efficient processes. KINTEK specializes in high-quality lab equipment and consumables tailored for biomass analysis, from sample preparation to energy conversion testing. Our solutions help you overcome logistical and economic challenges by providing the tools for consistent, reproducible results.

Let KINTEK empower your sustainable energy research. Contact our experts today to discuss how our equipment can streamline your biomass production workflows and support your environmental goals.

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Heating Pyrolysis Plant

- Laboratory Manual Hydraulic Pellet Press for Lab Use

- Evaporation Boat for Organic Matter

People Also Ask

- Is biomass renewable or non renewable energy? The Truth About Sustainable Power

- What are 3 renewable alternative energy sources? Solar, Wind, and Hydropower Explained

- What are the 5 main heat treatments? Master Metal Hardness, Toughness, and Ductility

- What are the two heat treatment processes? Softening vs. Hardening Explained

- How do you calculate the capacity of a filter press? Use Pilot Testing for Accurate Sizing

- What is DFT coating thickness? Ensure Quality and Performance with Precise Measurement

- What is heat treatment in simple terms? A Guide to Transforming Material Properties

- What is ferronickel used for? The Essential Alloy for Stainless Steel Production