At its core, silicon carbide (SiC) is a high-performance ceramic compound known for its exceptional hardness, high-temperature stability, and chemical inertness. These properties make it a critical material for applications in extreme environments where conventional metals and ceramics would fail, from industrial furnaces to semiconductor manufacturing.

The key to understanding silicon carbide is recognizing that it is not a single material, but a family of materials. Its final characteristics are heavily dictated by its manufacturing process, which tunes the material for specific uses ranging from high-purity electronics to porous thermal insulators.

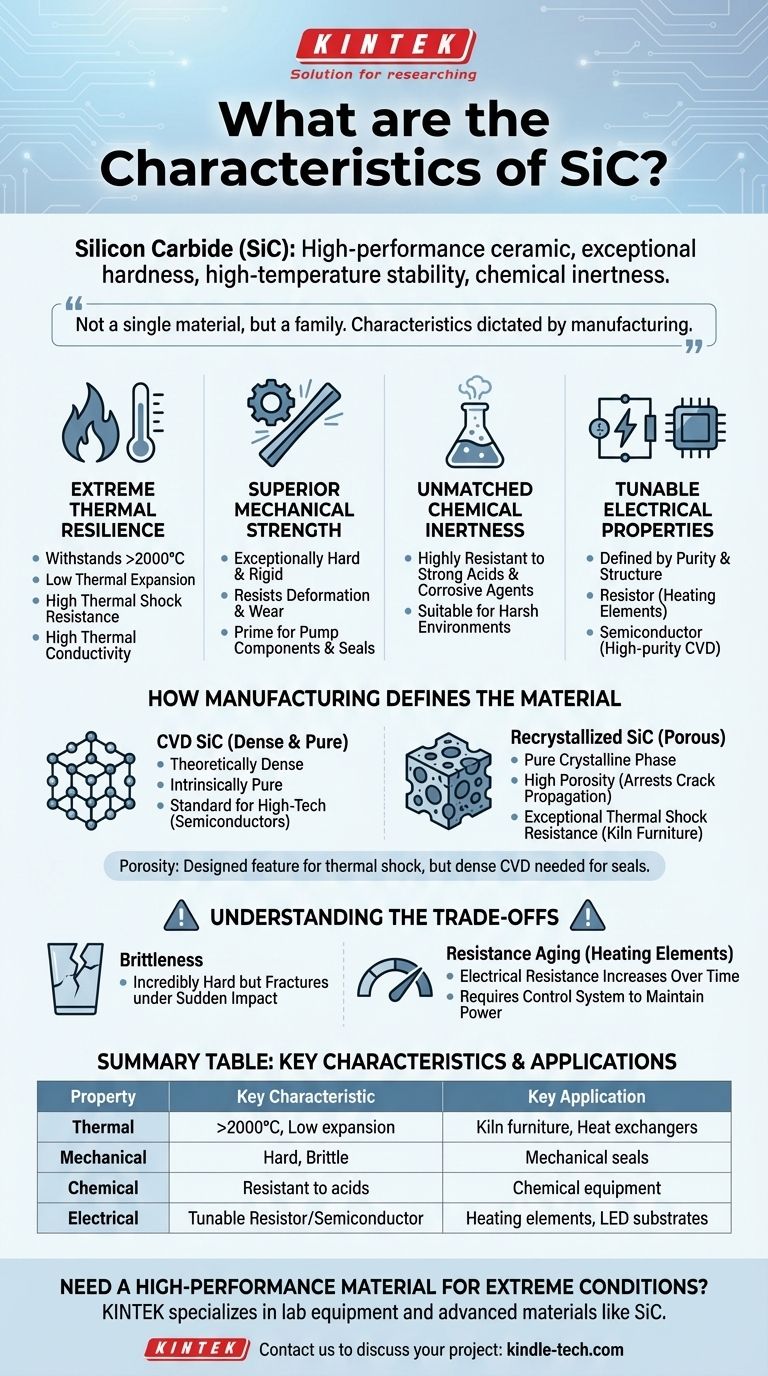

The Core Pillars of SiC Performance

Silicon carbide’s value is rooted in a combination of thermal, mechanical, and chemical properties that are rare to find in a single material.

Extreme Thermal Resilience

SiC excels in high-temperature environments. It has an extremely high refractoriness, able to withstand temperatures greater than 2000°C without melting.

This is complemented by a low coefficient of thermal expansion and excellent resistance to thermal shock. This means it can endure rapid heating and cooling cycles without cracking, a critical feature for furnace components and combustion nozzles.

Its high thermal conductivity allows it to efficiently dissipate or transfer heat, making it ideal for heat exchangers and high-temperature furnace guide rails.

Superior Mechanical Strength

SiC is an exceptionally hard and rigid material. This inherent strength means it resists deformation and wear, making it a prime candidate for physically demanding roles like pump components and mechanical seals.

While it is not easily deformed, this hardness comes with a trade-off, which is discussed below.

Unmatched Chemical Inertness

Silicon carbide demonstrates remarkable chemical stability. It is highly resistant to strong acids and other corrosive agents.

This inertness makes it suitable for use in harsh chemical processing environments where other materials would quickly degrade.

Tunable Electrical Properties

The electrical behavior of SiC is not fixed; it is defined by its purity and crystalline structure. This versatility is one of its most powerful attributes.

It can be engineered to act as a resistor, forming the basis of robust heating elements for industrial furnaces operating up to 1500°C.

Alternatively, high-purity, theoretically dense SiC (produced via Chemical Vapor Deposition, or CVD) acts as a semiconductor, forming substrates for modern LEDs and high-power electronics.

How Manufacturing Defines the Material

You cannot select the right SiC without understanding how it's made. The manufacturing process fundamentally alters the material's density, purity, and resulting performance.

Density and Purity (CVD vs. Recrystallized)

CVD silicon carbide is theoretically dense and intrinsically pure, with very low electrical resistivity. This makes it the standard for high-tech applications like semiconductor substrates where purity and inertness are paramount.

Recrystallized silicon carbide, by contrast, has a pure crystalline phase but contains high porosity. This porous structure is key to its exceptional thermal shock resistance, making it ideal for kiln furniture.

The Role of Porosity

Porosity is not always a defect; in SiC, it can be a designed feature. The voids in porous, recrystallized SiC help to arrest crack propagation, dramatically improving its ability to survive rapid temperature changes.

For applications requiring a perfect seal or chemical barrier, however, a dense form like CVD SiC is necessary.

Understanding the Trade-offs

No material is perfect. Acknowledging the limitations of SiC is essential for successful implementation.

Hardness vs. Brittleness

The primary trade-off for SiC is its brittleness. While it is incredibly hard and resists scratches and wear, it can fracture or shatter under sudden, sharp impact. It does not plastically deform like a metal.

Designs using SiC must account for this, ensuring components are not subjected to unexpected impact loads.

Resistance Aging in Heating Elements

When used as a resistive heating element, SiC's electrical resistance gradually increases over its operational life. This is a predictable phenomenon known as aging.

This requires a control system, such as an auto-transformer with multiple taps, to increase the voltage over time to maintain constant power output and temperature. This is a critical consideration for furnace design and maintenance.

Making the Right Choice for Your Application

Selecting the correct type of silicon carbide depends entirely on your primary engineering goal.

- If your primary focus is extreme temperature and thermal shock: Choose a porous, recrystallized SiC for applications like kiln furniture, heat exchangers, or combustion nozzles.

- If your primary focus is electronic performance and purity: You need a dense, high-purity CVD SiC for semiconductor substrates or chemically inert process components.

- If your primary focus is reliable heating elements: Select SiC rods, but ensure your design includes a control system to compensate for resistance aging over the component's lifespan.

- If your primary focus is chemical and wear resistance: SiC is an excellent choice for pump parts or seals, but your mechanical design must protect the components from impact to mitigate their brittleness.

Ultimately, silicon carbide provides an unparalleled solution for applications where conventional materials simply cannot survive.

Summary Table:

| Property | Key Characteristic | Key Application |

|---|---|---|

| Thermal | Withstands >2000°C, low thermal expansion, high thermal shock resistance | Kiln furniture, heat exchangers, furnace components |

| Mechanical | Extreme hardness and wear resistance, but brittle | Mechanical seals, pump components |

| Chemical | Highly resistant to strong acids and corrosive agents | Chemical processing equipment |

| Electrical | Tunable from resistor (heating elements) to semiconductor (electronics) | Heating elements, LED/semiconductor substrates |

Need a high-performance material for extreme conditions? Silicon carbide's unique combination of properties makes it ideal for demanding applications in labs and industry. KINTEK specializes in providing high-quality lab equipment and consumables, including solutions leveraging advanced materials like SiC. Let our experts help you select the right material for your specific thermal, mechanical, or chemical challenges. Contact our team today to discuss how SiC can enhance your project's performance and durability.

Visual Guide

Related Products

- Silicon Carbide (SIC) Ceramic Sheet Wear-Resistant Engineering Advanced Fine Ceramics

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Precision Machined Silicon Nitride (SiN) Ceramic Sheet for Engineering Advanced Fine Ceramics

- Hexagonal Boron Nitride HBN Ceramic Ring

- Conductive Boron Nitride BN Ceramics Composite for Advanced Applications

People Also Ask

- What are ceramic and its applications? From Pottery to Spacecraft, Unlocking Material Potential

- Why is alumina used in furnaces? Achieve Unmatched Heat Resistance and Purity

- At what temperature does ceramic melt? A Guide to Ceramic Heat Resistance

- Why do ceramics need to be sintered? Unlock Strength and Durability Through High-Temperature Fusion

- What is the temperature for ceramic parts sintering? A Guide to Material-Specific Sintering Cycles

- How are ceramic rods made? From Powder to Precision for High-Temp Applications

- Why is silicon carbide so important? Unlock Superior Performance in Extreme Conditions

- Why is high-purity alumina (Al2O3) preferred over quartz for steam oxidation? Ensure Data Integrity at 1773 K