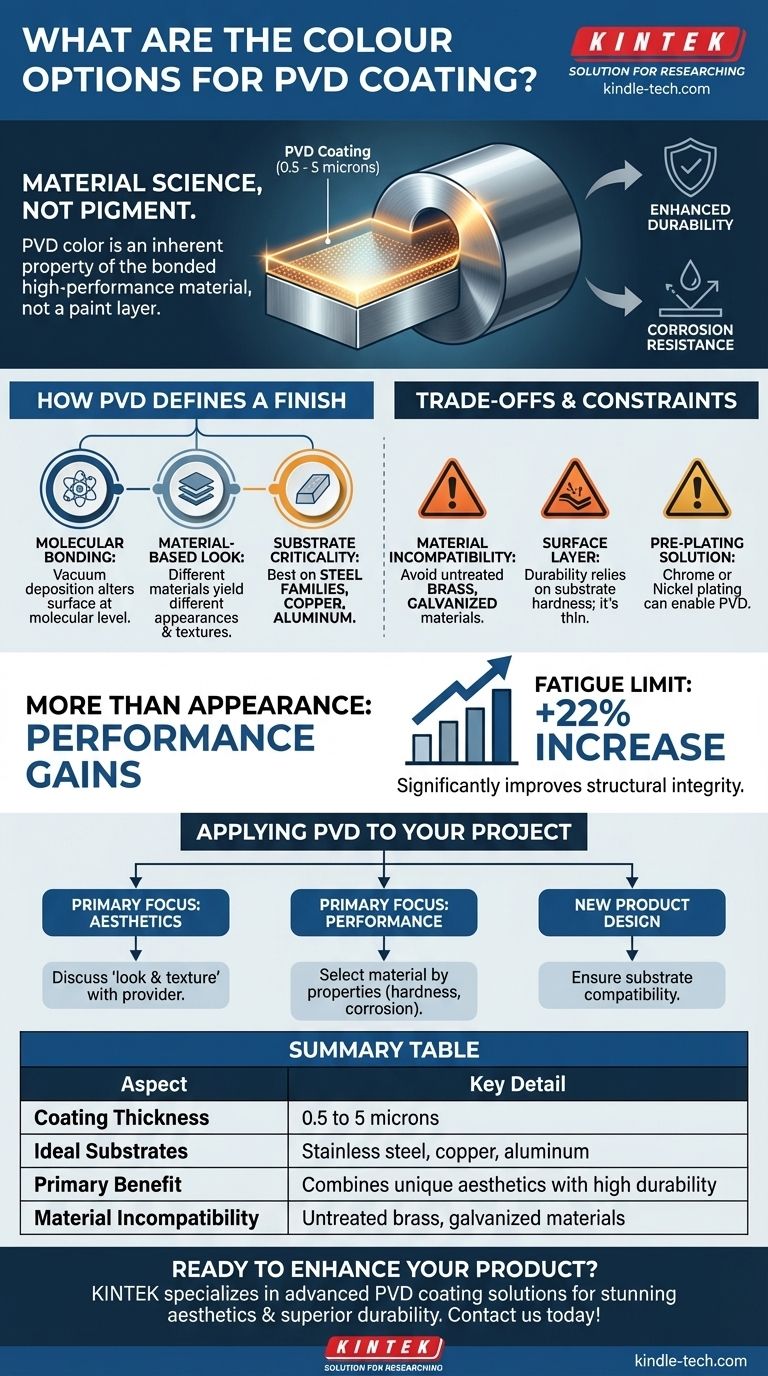

While specific color palettes are not detailed, Physical Vapor Deposition (PVD) is an advanced finishing technique that achieves a variety of "interesting looks and textures," particularly on stainless steel. The final appearance is not created by pigments but is an inherent property of the ultra-thin, molecular-level coating applied to the metal's surface, which also significantly enhances its durability and corrosion resistance.

The "color" in a PVD coating is not a separate layer of paint; it is the visible property of a specific, high-performance ceramic or metallic material bonded to the substrate. Therefore, choosing a PVD finish is a decision about both aesthetics and engineering performance.

How PVD Defines a Product's Finish

PVD is fundamentally different from traditional coating methods like painting or plating. It is a vacuum deposition process that alters the surface of a material on a molecular level.

It's About Material Science, Not Pigment

The final look of a PVD-coated product is a direct result of the material used for the coating. Different materials produce different appearances and performance characteristics.

The process involves bonding a very thin layer—ranging from 0.5 to five microns—of a specific metallic or ceramic compound onto the base material, or substrate.

The Substrate Is Critical

The properties and success of the PVD coating are heavily influenced by the underlying material. The coating adheres best and performs optimally on specific types of metal.

Materials well-suited for PVD include all steel families, especially high-alloy and stainless steels, as well as non-ferrous metals like copper and aluminum.

More Than Just Appearance

While PVD provides unique aesthetic options, its primary technical benefits are performance-based. The coating is exceptionally hard and highly resistant to corrosion and oxidation.

For example, certain coatings can increase a metal alloy's fatigue limit by 22% and its endurance by 7%, demonstrating that the choice of finish has a measurable impact on the part's structural integrity.

Understanding the Trade-offs and Constraints

While powerful, the PVD process has specific requirements and limitations that are critical to understand before beginning a project.

Strict Material Incompatibility

The PVD process takes place in a high-vacuum environment, and certain materials cannot tolerate these conditions. This makes them unsuitable for coating.

Specifically, brass without a galvanic layer (like nickel or chrome plating) and galvanized materials are not compatible with the PVD process and should be avoided.

The Coating Is Only a Surface Layer

Although the PVD coating itself is extremely hard, it remains a very thin film. Its durability is therefore dependent on the hardness of the substrate beneath it.

A hard PVD coating on a soft substrate can still be damaged if the underlying material is dented or deformed. The substrate provides the foundational support for the coating.

Pre-Plating Can Be a Solution

For some materials, a preparatory step can make them suitable for PVD. The references note that chrome or nickel-plated metal products can be successfully coated.

This adds a step to the manufacturing process but expands the range of base materials that can benefit from a PVD finish.

How to Apply This to Your Project

Your decision should be guided by a clear understanding of your project's primary goal, balancing aesthetic desires with engineering necessities.

- If your primary focus is a specific look: Discuss your desired "look and texture" with your coating provider to see which of their available PVD materials will achieve it.

- If your primary focus is durability and performance: Select the PVD coating material based on its documented properties like hardness, corrosion resistance, and fatigue strength.

- If you are designing a new product: Ensure your chosen substrate material, such as stainless steel or a high-alloy steel, is fully compatible with the PVD process to guarantee a successful outcome.

Ultimately, selecting the right PVD finish is about choosing the material that delivers the ideal combination of appearance and performance for your application.

Summary Table:

| Aspect | Key Detail |

|---|---|

| Coating Thickness | 0.5 to 5 microns |

| Ideal Substrates | Stainless steel, copper, aluminum |

| Primary Benefit | Combines unique aesthetics with high durability |

| Material Incompatibility | Untreated brass, galvanized materials |

Ready to enhance your product with a high-performance PVD finish? KINTEK specializes in advanced lab equipment and consumables, including PVD coating solutions that deliver both stunning aesthetics and superior durability for your laboratory and industrial applications. Contact us today to discuss how our expertise can bring your project to life!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- VHP Sterilization Equipment Hydrogen Peroxide H2O2 Space Sterilizer

- Molybdenum Tungsten Tantalum Special Shape Evaporation Boat

People Also Ask

- What is an example of PECVD? RF-PECVD for High-Quality Thin Film Deposition

- What are the benefits of PECVD? Achieve Superior Low-Temperature Thin Film Deposition

- What is plasma activated chemical vapour deposition method? A Low-Temperature Solution for Advanced Coatings

- What are the advantages of PECVD? Enable Low-Temperature, High-Quality Thin-Film Deposition

- Why does PECVD commonly use RF power input? For Precise Low-Temperature Thin Film Deposition