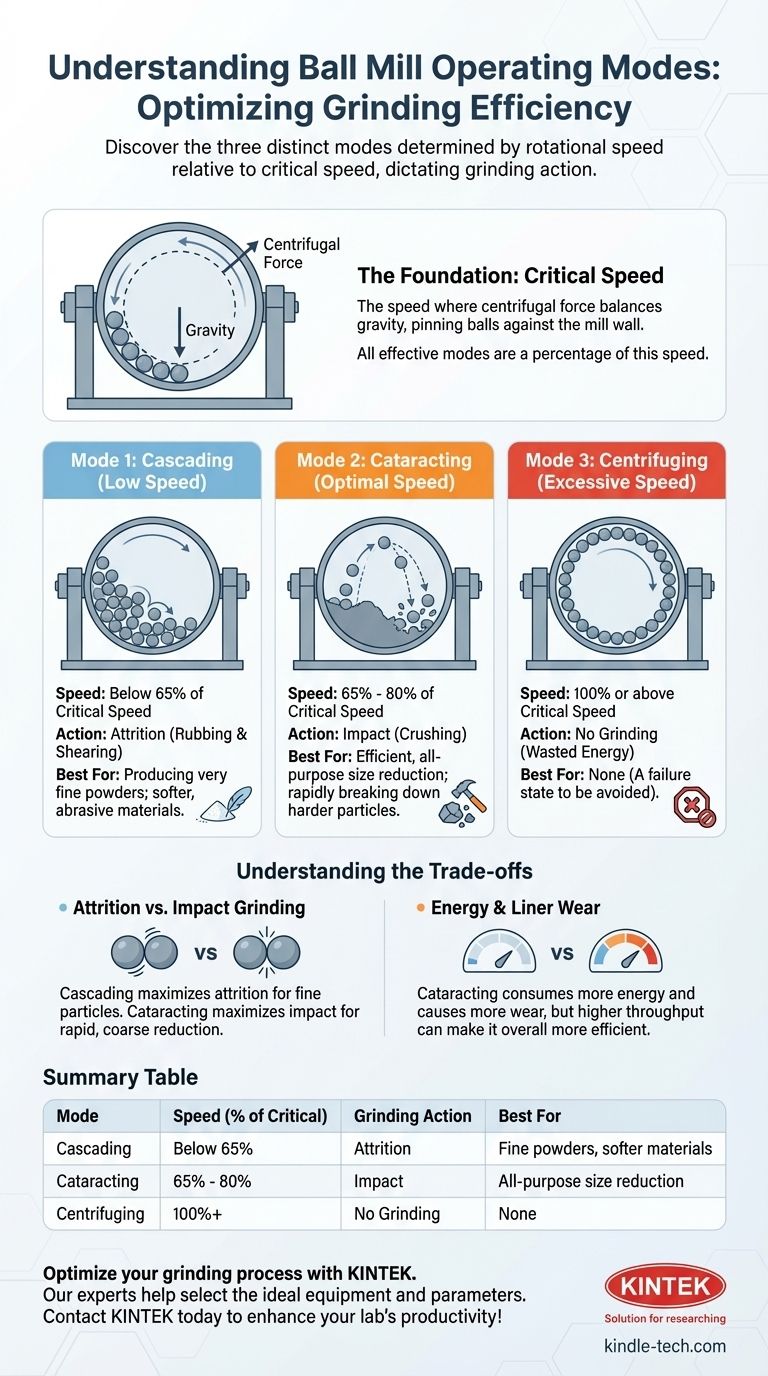

At its core, a ball mill has three distinct operating modes determined by its rotational speed relative to a calculated "critical speed." These modes are known as Cascading, Cataracting, and Centrifuging. Each mode dictates how the grinding media (the balls) move and, consequently, whether the primary grinding force is attrition (rubbing) or impact (crushing).

The speed of a ball mill is not simply a measure of how fast it works; it is the fundamental control that determines the type of grinding action that occurs. Selecting the correct mode is the single most important factor in achieving efficient particle size reduction.

The Foundation: Understanding Critical Speed

Before exploring the modes, you must understand the concept of critical speed. This is a calculated value, not an arbitrary setting.

What is Critical Speed?

Critical speed is the theoretical rotational speed at which the outermost layer of grinding balls will be pinned against the mill's inner wall by centrifugal force. At this speed, the force pushing the balls outward perfectly balances the force of gravity pulling them down.

Why It Matters

Operating at or above critical speed results in centrifuging, where the balls and material rotate with the mill as one mass. This completely stops the tumbling and grinding action, rendering the mill ineffective and wasting energy. All effective operating modes are therefore defined as a percentage of this critical speed.

The Three Primary Operating Modes

The motion of the grinding media changes dramatically based on how close the mill's speed is to the critical speed. This creates three distinct modes.

Mode 1: Cascading (Low Speed)

At lower speeds, typically below 65% of critical speed, the grinding media tumbles gently. The balls are lifted a short way up the side of the shell and then cascade or slide back down over the rest of the charge.

This motion emphasizes attrition, a rubbing and shearing action, as the balls grind against each other and the material. Cascading is ideal for producing a very fine product where impact might be inefficient or undesirable.

Mode 2: Cataracting (Optimal Speed)

This is the most common and generally most efficient operating mode, occurring between 65% and 80% of critical speed. The balls are carried further up the mill wall before detaching and following a parabolic arc, crashing down onto the material at the bottom of the charge.

This mode produces a powerful impact force, which is excellent for rapid and efficient size reduction of most materials. It represents the optimal balance between impact and attrition for general-purpose grinding.

Mode 3: Centrifuging (Excessive Speed)

When the mill operates at or above 100% of the critical speed, centrifugal force takes over completely. The grinding media and material are locked against the mill liner and rotate in place.

No relative motion occurs between the balls, and therefore no grinding takes place. This is a state of failure that must always be avoided, as it consumes energy with zero productive output.

Understanding the Trade-offs

Choosing a mode is a matter of balancing efficiency, desired particle size, and operational costs.

Attrition vs. Impact Grinding

The Cascading mode maximizes attrition, which is effective for fine grinding and processing softer, abrasive materials. The Cataracting mode maximizes impact, which is better for breaking down harder, coarser particles quickly. The right choice depends entirely on your starting material and end-product goals.

Energy Consumption and Liner Wear

Higher speeds demand more energy. The Cataracting mode consumes significantly more power than the Cascading mode but often results in a higher throughput, making it more energy-efficient overall for many tasks.

However, the powerful impacts of the Cataracting mode also cause more rapid wear on the steel balls and the internal liner of the mill, increasing maintenance costs over time.

Selecting the Right Mode for Your Goal

Your operational choice should be a deliberate decision based on the desired outcome.

- If your primary focus is efficient, all-purpose grinding: Operate in the Cataracting mode (65-80% of critical speed) to achieve a powerful balance of impact and attrition.

- If your primary focus is producing a very fine powder: Operate in the Cascading mode (<65% of critical speed) to maximize grinding through attrition and minimize forceful impacts.

- If your primary focus is avoiding wasted energy and wear: Ensure your speed never reaches the critical speed, which causes centrifuging and stops all grinding.

Ultimately, mastering your ball mill means understanding that its speed is the key that unlocks the specific grinding force you need for your process.

Summary Table:

| Mode | Speed (% of Critical) | Grinding Action | Best For |

|---|---|---|---|

| Cascading | Below 65% | Attrition (Rubbing/Shearing) | Producing fine powders, softer materials |

| Cataracting | 65% - 80% | Impact (Crushing) | Efficient, all-purpose size reduction |

| Centrifuging | 100% or above | No Grinding | None (must be avoided) |

Optimize your grinding process with the right equipment from KINTEK.

Understanding the operating modes of your ball mill is crucial for achieving the perfect particle size and maximizing efficiency. Whether you need the fine grinding power of the Cascading mode or the high-impact efficiency of the Cataracting mode, KINTEK has the durable, high-performance lab equipment and consumables to meet your specific laboratory needs.

Let our experts help you select the ideal ball mill and operating parameters for your application. Contact KINTEK today to discuss your requirements and enhance your lab's productivity!

Visual Guide

Related Products

- Stainless Steel Laboratory Ball Mill for Dry Powder and Liquid with Ceramic Polyurethane Lining

- High Energy Planetary Ball Mill Machine for Laboratory Horizontal Tank Type

- Laboratory Ball Mill Jar Mill with Metal Alloy Grinding Jar and Balls

- Mini Planetary Ball Mill Machine for Laboratory Milling

- Laboratory Single Horizontal Jar Mill

People Also Ask

- What role does a planetary ball mill play in the preparation of Fe3Si? Mastering Atomic Mixing for Phase Purity

- What is the maximum size reduction in a ball mill? Achieve Your Optimal Grind Efficiency

- What is the function of a planetary ball mill in MOF glass preparation? Master High-Energy Solid-State Amorphization

- How do planetary ball mills influence ceramic nanocomposites? Master High-Energy Material Refinement

- What is the core function of a planetary ball mill in TiB2-TiN-WC composite preparation? Achieve Superior Material Refinement

- What is the function of a planetary ball mill for LCFA powders? Achieve High-Energy Refinement for Perovskite Oxides

- Why is the ball milling process utilized in the preparation of Al2O3-SiC pre-mixed powders? Boost Sintering Performance

- What is the specific role of a planetary ball mill in the preparation of Ag-SnO2-Y2O3 composite powders?