The primary disadvantages of a ball mill are its slow processing speed, high levels of noise and vibration, and its inability to effectively grind soft or fibrous materials. Furthermore, the constant abrasive action can cause wear on the mill's internal components, leading to a significant risk of product contamination.

While a ball mill is exceptionally good at producing very fine, uniform powders, its effectiveness comes with clear trade-offs. The core limitations are rooted in its brute-force mechanical nature, which creates challenges in speed, material compatibility, and product purity.

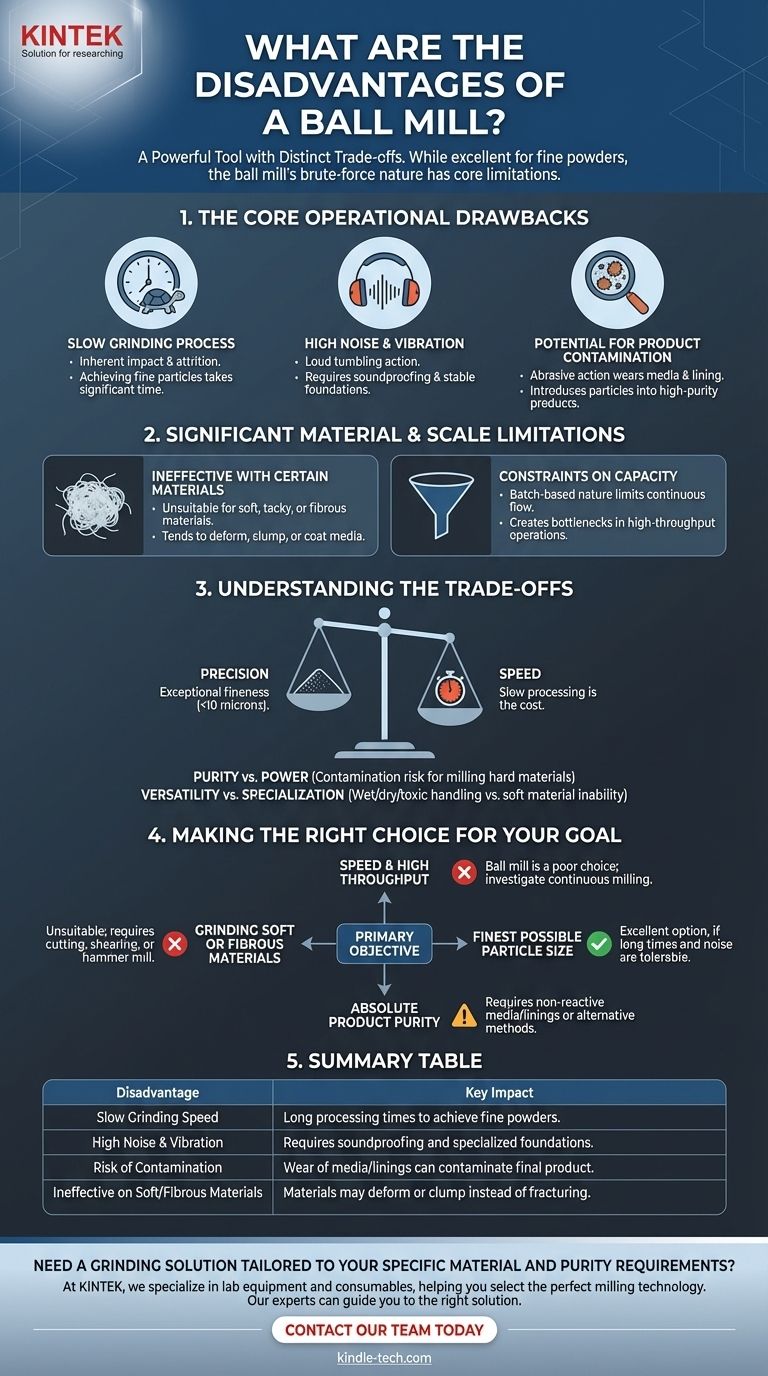

The Core Operational Drawbacks

A ball mill's design, which involves tumbling heavy media inside a rotating drum, is the source of both its strengths and its most significant operational weaknesses.

Slow Grinding Process

A ball mill reduces particle size through a combination of impact and attrition. This is an inherently random and repetitive process, making it significantly slower than many other grinding methods.

Achieving a target particle size, especially in the low-micron range, requires considerable time.

High Noise and Vibration

The cascading and tumbling of steel or ceramic balls inside a large metal cylinder is an extremely loud process. This often requires dedicated soundproofing or placement in isolated areas of a facility.

The rotation of the heavy, off-balance load also generates strong vibrations, which can necessitate specialized foundations to prevent structural interference.

Potential for Product Contamination

The grinding action is highly abrasive. Over time, this wears down both the grinding media (the balls) and the internal lining of the mill.

This wear introduces fine particles of the media and lining material directly into your product. For high-purity applications, such as pharmaceuticals or electronics, this contamination can be a critical failure point.

Significant Material and Scale Limitations

A ball mill is a powerful tool, but it is not a universal solution. Its mechanism is highly effective for some materials but completely unsuitable for others.

Ineffectiveness with Certain Materials

Ball mills excel at grinding hard, brittle materials. However, they are unable to properly reduce materials that are soft, tacky, or fibrous.

Instead of fracturing, these materials tend to deform, clump together, or coat the grinding media, rendering the milling process ineffective.

Constraints on Capacity

While ball mills can be built on a large scale, their batch-based nature and slow processing speed can create bottlenecks in high-throughput, continuous operations.

For industries requiring the rapid processing of massive quantities, other milling systems may offer a more efficient solution.

Understanding the Trade-offs

The disadvantages of a ball mill must be weighed against its distinct advantages. Choosing this technology is about accepting a series of deliberate trade-offs to achieve a specific outcome.

Precision vs. Speed

The slow grinding process is a direct trade-off for achieving an exceptionally fine and uniform particle size, often down to 10 microns or less. If your goal is ultimate fineness, the lack of speed may be an acceptable price.

Purity vs. Power

The risk of contamination is the price paid for the ability to mill extremely hard and abrasive materials. For many industrial applications like cement or mineral processing, slight contamination from steel media is irrelevant.

Versatility vs. Specialization

While it cannot handle soft materials, a ball mill's ability to operate in either wet or dry conditions and be fully enclosed for processing toxic materials makes it highly versatile within its specific domain of brittle material grinding.

Making the Right Choice for Your Goal

To decide if a ball mill is appropriate, you must align its characteristics with your primary objective.

- If your primary focus is speed and high throughput: A ball mill is likely a poor choice; investigate alternative continuous milling systems.

- If your primary focus is achieving the finest possible particle size: The ball mill is an excellent option, provided you can tolerate the long processing times and manage noise.

- If your primary focus is absolute product purity: You must carefully select non-reactive linings and media or consider a different milling method entirely to avoid contamination.

- If your primary focus is grinding soft or fibrous materials: A ball mill is unsuitable; you require a cutting, shearing, or hammer mill instead.

Understanding these inherent limitations allows you to correctly determine if a ball mill's powerful grinding capabilities align with your specific material and production goals.

Summary Table:

| Disadvantage | Key Impact |

|---|---|

| Slow Grinding Speed | Long processing times to achieve fine powders. |

| High Noise & Vibration | Requires soundproofing and specialized foundations. |

| Risk of Contamination | Wear of media/linings can contaminate the final product. |

| Ineffective on Soft/Fibrous Materials | Materials may deform or clump instead of fracturing. |

Need a grinding solution tailored to your specific material and purity requirements?

At KINTEK, we specialize in lab equipment and consumables, helping you select the perfect milling technology for your application. Whether you need to avoid contamination, increase throughput, or process challenging materials, our experts can guide you to the right solution.

Contact our team today for a personalized consultation and discover how we can optimize your laboratory processes.

Visual Guide

Related Products

- High Energy Planetary Ball Mill Machine for Laboratory Horizontal Tank Type

- Mini Planetary Ball Mill Machine for Laboratory Milling

- High Energy Planetary Ball Mill Milling Machine for Laboratory

- Liquid Nitrogen Cryogenic Grinder Mill Cryomill Airflow Ultrafine Pulverizer

- Small Injection Molding Machine for Lab Use

People Also Ask

- What is the role of a planetary ball mill in the synthesis of Li2S–P2S5 sulfide solid-state electrolytes?

- What role does a planetary ball mill play in SHS? Optimize Powder Activation for Superior Alloy Synthesis

- What is the function of a high-energy planetary ball mill in zirconium-doped CaO synthesis? Optimize Material Stability

- What is the role of a planetary ball mill in the preparation of NiCr-Al2O3-SrCO3 composite powders? Enhanced Homogeneity

- What is the specific role of a high-energy planetary ball mill in the synthesis of Ag-doped sulfide solid-state electrolytes?