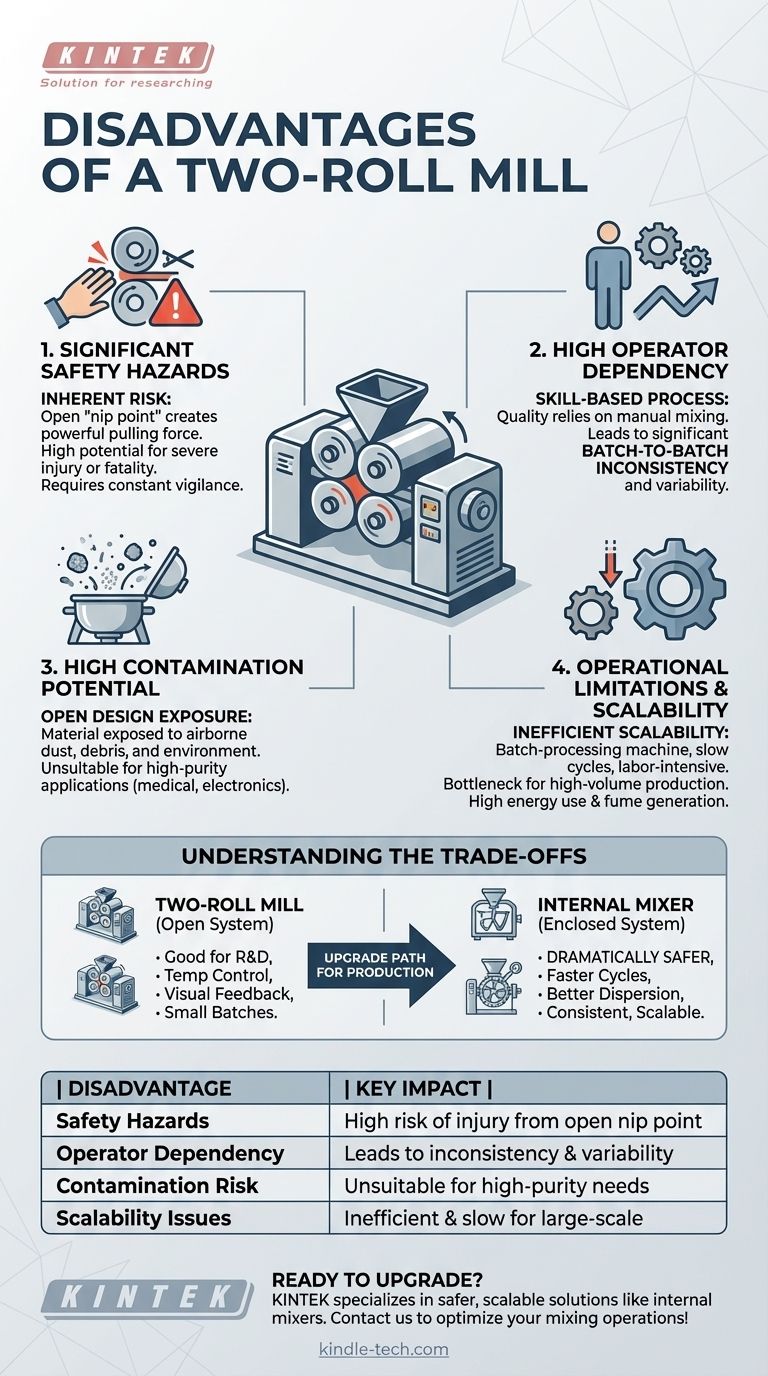

While versatile for specific applications, the primary disadvantages of a two-roll mill are significant safety risks, heavy reliance on operator skill leading to process inconsistency, and inherent limitations in scalability for high-volume production. Its open design also introduces a high potential for material contamination and requires robust environmental controls to manage fumes.

A two-roll mill is a powerful tool for lab-scale development and small-batch processing. However, its fundamental design creates operational and safety challenges that are largely solved by more modern, enclosed systems like internal mixers, especially in production environments.

The Core Challenge: An Open, Manual Design

The defining characteristic of a two-roll mill is its pair of exposed, counter-rotating rolls. While this allows for direct observation and manual manipulation of the material, this very design is the source of its most significant drawbacks.

Significant Safety Hazards

The most critical disadvantage is the inherent safety risk. The space where the two rolls meet, known as the nip point, creates a powerful pulling force that can easily entangle an operator's hands, limbs, or clothing, leading to severe or fatal injuries.

Modern mills have safety features like emergency stop bars and braking systems, but the fundamental hazard of an open nip point remains, demanding rigorous training and constant vigilance.

High Operator Dependency

The quality and consistency of the final compound are heavily reliant on the skill of the operator. The process involves manually cutting, folding, and feeding the material back into the nip to achieve a homogeneous mix.

This manual intervention introduces significant batch-to-batch variability. Two different operators, or even the same operator on different days, can produce slightly different results, which is unacceptable for applications requiring high precision.

High Potential for Contamination

The open design exposes the material to the surrounding environment throughout the mixing process. Airborne dust, debris, and other contaminants can easily be incorporated into the batch.

This makes two-roll mills unsuitable for producing high-purity compounds, such as those used in medical, pharmaceutical, or electronic applications, without extensive environmental controls.

Operational and Production Limitations

Beyond the immediate design flaws, two-roll mills present practical limitations for modern manufacturing environments.

Inefficient for Large-Scale Production

Two-roll mills are fundamentally batch-processing machines with limited capacity. They are labor-intensive and have longer mixing cycles compared to automated, enclosed mixers.

This makes them a bottleneck in any high-volume production line. Their role in large-scale manufacturing is typically relegated to warming up pre-mixed material or for specialized, small-run tasks.

Fume Generation and Energy Use

The intense shearing and heating of polymers and elastomers on a mill can generate significant fumes and volatile organic compounds (VOCs). This necessitates costly and extensive ventilation and fume extraction systems to ensure a safe working environment.

Additionally, these are energy-intensive machines, requiring powerful motors to turn the rolls against the resistance of highly viscous materials.

Understanding the Trade-offs: Mill vs. Internal Mixer

To fully grasp the disadvantages, it's useful to compare the two-roll mill to its primary alternative: the enclosed internal mixer (such as a Banbury mixer).

Where a Two-Roll Mill Excels

A mill offers superior temperature control, as the material is constantly exposed to the air and the rolls can be precisely heated or cooled. It also allows an experienced operator to visually inspect the compound and make real-time adjustments.

Where an Internal Mixer is Superior

An internal mixer is dramatically safer because the entire process is enclosed. It provides faster mixing cycles, achieves better dispersion of ingredients, and is far less dependent on operator skill, leading to superior batch-to-batch consistency. Its design is ideal for integration into automated, high-volume production lines.

Making the Right Choice for Your Application

Choosing the correct equipment requires aligning its capabilities with your primary goal.

- If your primary focus is R&D and material development: The two-roll mill is an excellent tool, offering the flexibility and direct visual feedback needed to create and test new formulations.

- If your primary focus is small-batch or custom color mixing: A mill can be effective due to its relative ease of cleaning between batches, provided strict safety and quality control protocols are in place.

- If your primary focus is high-volume, repeatable manufacturing: The safety risks, operator dependency, and low throughput make an internal mixer the far more logical and efficient choice.

Ultimately, understanding the inherent disadvantages of a two-roll mill is key to deploying it effectively for tasks where its unique strengths are the priority.

Summary Table:

| Disadvantage | Key Impact |

|---|---|

| Safety Hazards | High risk of injury from the open nip point |

| Operator Dependency | Leads to batch-to-batch inconsistency |

| Contamination Risk | Unsuitable for high-purity applications |

| Scalability Issues | Inefficient and slow for large-scale production |

Ready to upgrade your mixing process for better safety and consistency?

While a two-roll mill is a versatile tool for lab-scale development, its inherent disadvantages can hinder production efficiency and safety. KINTEK specializes in advanced lab equipment and consumables, offering safer, more consistent, and scalable solutions like internal mixers for your laboratory needs.

Contact us today to discuss how we can help you optimize your mixing operations!

Visual Guide

Related Products

- Laboratory Single Horizontal Jar Mill

- Laboratory Planetary Ball Mill Rotating Ball Milling Machine

- Laboratory Jar Mill with Agate Grinding Jar and Balls

- Laboratory Ten-Body Horizontal Jar Mill for Lab Use

- High Energy Vibratory Laboratory Ball Mill Double Tank Type

People Also Ask

- What are the advantages of polyurethane ball mill jars for silicon nitride? Ensure Purity & Prevent Metal Contamination

- What is the benefit of using tungsten carbide (WC) milling jars and balls? Achieve High-Energy Milling Efficiency

- Why are silicon nitride or zirconia preferred for milling iodo-vanadate-lead precursors? Ensure High Purity Results

- Why are excellent sealing and corrosion resistance required for WC-10Co ball milling? Ensure High-Purity Mixing Results

- What is the ball mill based on the principle of? Impact and Attrition for Efficient Grinding