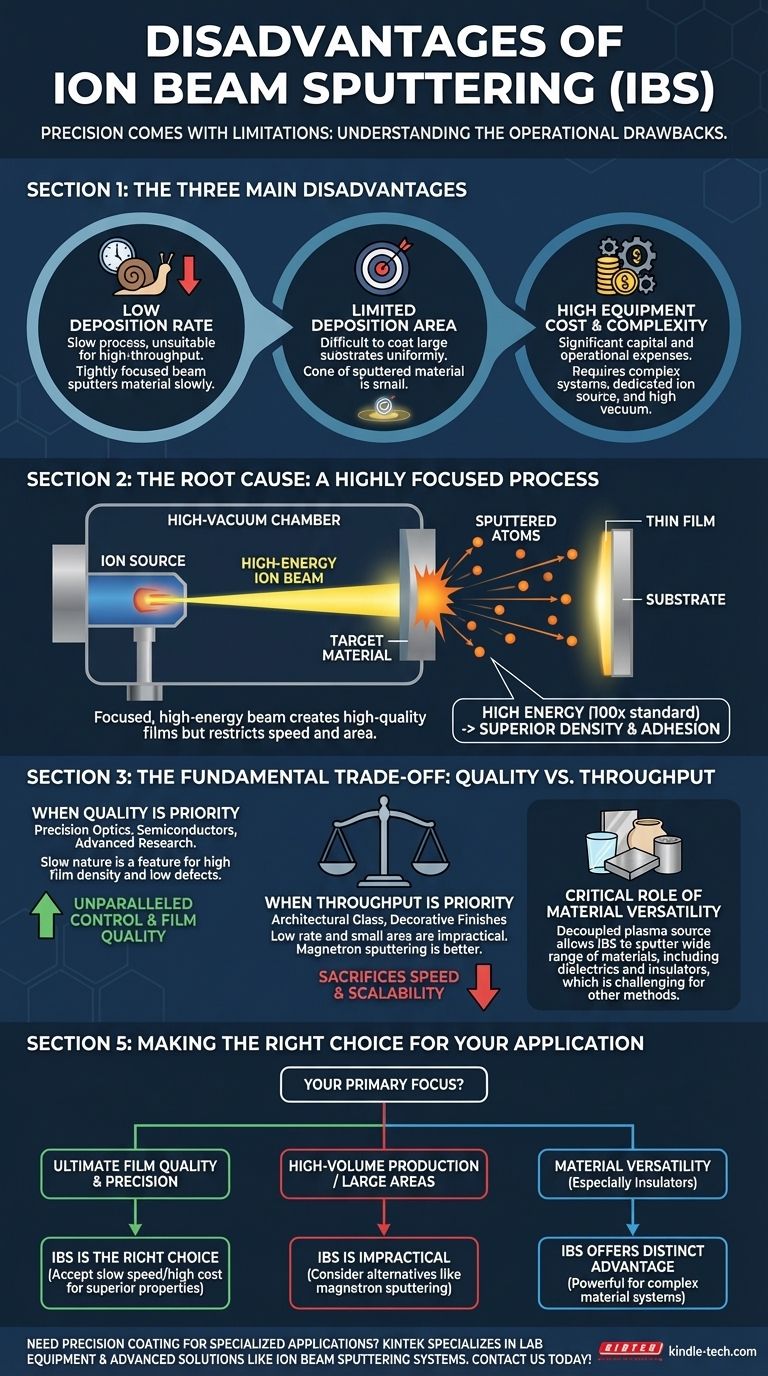

While known for its precision, ion beam sputtering has several key operational limitations. The primary disadvantages are a low deposition rate and a small deposition area, which make it unsuitable for coating large surfaces uniformly. Furthermore, the equipment is complex and carries a high operating cost, restricting its use to applications where its unique benefits outweigh these drawbacks.

Ion beam sputtering sacrifices speed and scalability for unparalleled control and film quality. Its disadvantages are fundamentally tied to the very process that gives it its strengths: a focused, high-energy, and highly controlled ion beam.

The Root Cause: A Highly Focused Process

To understand the limitations of ion beam sputtering (IBS), we must first understand how it works. Unlike other methods, IBS uses a dedicated ion source that is separate from the material target.

How the Ion Beam Works

The process takes place in a high-vacuum chamber. An ion source generates a focused, high-energy, and collimated beam of ions (typically from an inert gas like argon). This beam is directed at a target material, striking it with significant force.

This collision transfers momentum, dislodging or "sputtering" atoms from the target. These sputtered atoms then travel through the vacuum and deposit onto a substrate, forming a thin film.

Why This Process Creates High-Quality Films

The key advantage of IBS stems from the high energy and precise control of the ion beam. The sputtered particles have an average energy around 10 eV, which is roughly 100 times higher than particles in standard vacuum evaporation.

This high energy allows the deposited atoms to migrate on the substrate surface, settling into a dense, ordered structure. The result is a film with superior density, purity, and adhesion to the substrate.

Understanding the Practical Disadvantages

The same precision that makes IBS so effective for high-quality films is also the source of its main disadvantages.

Low Deposition Rate

Because the ion beam is so tightly focused and controlled, it sputters material from the target at a relatively slow rate. Processes like magnetron sputtering, which use a broader plasma discharge, can deposit material much more quickly.

This makes IBS a time-consuming process, ill-suited for applications that require high throughput.

Limited Deposition Area

The focused nature of the beam means it only bombards a small area of the target at any given time. Consequently, the cone of sputtered material is also limited in size.

This makes it very difficult to achieve a uniform film thickness across a large substrate. While techniques like substrate rotation can help, IBS is fundamentally designed for coating smaller components where precision is paramount.

Equipment Complexity and High Cost

An IBS system is mechanically complex. It requires a dedicated, stable ion source, a high-vacuum environment, and sophisticated power and control systems.

This complexity translates directly into higher capital equipment costs and increased operational expenses for maintenance and power consumption compared to simpler deposition technologies.

The Fundamental Trade-off: Quality vs. Throughput

The decision to use ion beam sputtering is a classic engineering trade-off. You are choosing to sacrifice speed and scale to gain exceptional control and quality.

When Quality is the Priority

For advanced applications, the drawbacks of IBS are acceptable. In fields like precision optics, semiconductor manufacturing, and advanced materials research, properties like film density, stoichiometry, and low defect counts are non-negotiable. The slow, deliberate nature of IBS is a feature, not a bug.

When Throughput is the Priority

For applications like coating architectural glass or applying decorative finishes, the primary goals are speed and cost-efficiency over large areas. Here, the low deposition rate and small area of IBS make it entirely impractical. Magnetron sputtering is the far more logical choice.

The Critical Role of Material Versatility

A key advantage that complicates this trade-off is versatility. Because the ion source is separate from the target, the target itself does not need to be electrically conductive.

This allows IBS to effectively sputter a wide range of materials, including dielectrics and insulators, which can be challenging for other methods.

Making the Right Choice for Your Application

Your choice of deposition method must align with your project's most critical outcome.

- If your primary focus is ultimate film quality and precision: The lower speed and higher cost of ion beam sputtering are acceptable trade-offs for achieving superior material properties.

- If your primary focus is high-volume production or coating large areas: The inherent limitations in deposition rate and area make IBS impractical; consider alternatives like magnetron sputtering.

- If your primary focus is material versatility, especially for insulators: IBS offers a distinct advantage by decoupling the plasma source from the target, making it a powerful tool for developing complex material systems.

Understanding these disadvantages allows you to leverage ion beam sputtering as the powerful, specialized tool it is, rather than misapplying it where speed and scale are paramount.

Summary Table:

| Disadvantage | Key Impact |

|---|---|

| Low Deposition Rate | Slow process, unsuitable for high-throughput applications |

| Limited Deposition Area | Difficult to coat large substrates uniformly |

| High Equipment Cost | Complex system with significant capital and operational expenses |

Need precision coating for specialized applications? KINTEK specializes in lab equipment and consumables, serving laboratory needs with advanced solutions like ion beam sputtering systems. Our expertise ensures you get the right equipment for high-quality film deposition with superior control and material versatility. Contact us today to discuss how our solutions can meet your specific research or production requirements!

Visual Guide

Related Products

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- Vacuum Hot Press Furnace Machine for Lamination and Heating

People Also Ask

- How are reactants introduced into the reaction chamber during a CVD process? Mastering Precursor Delivery Systems

- What is the role of the HF-CVD system in preparing BDD electrodes? Scalable Solutions for Boron-Doped Diamond Production

- What is microwave plasma CVD? A Guide to High-Purity Diamond and Material Synthesis

- What is the hot filament chemical vapour deposition of diamond? A Guide to Synthetic Diamond Coating

- What are the advantages of using HFCVD for BDD electrodes? Scaling Industrial Diamond Production Efficiently