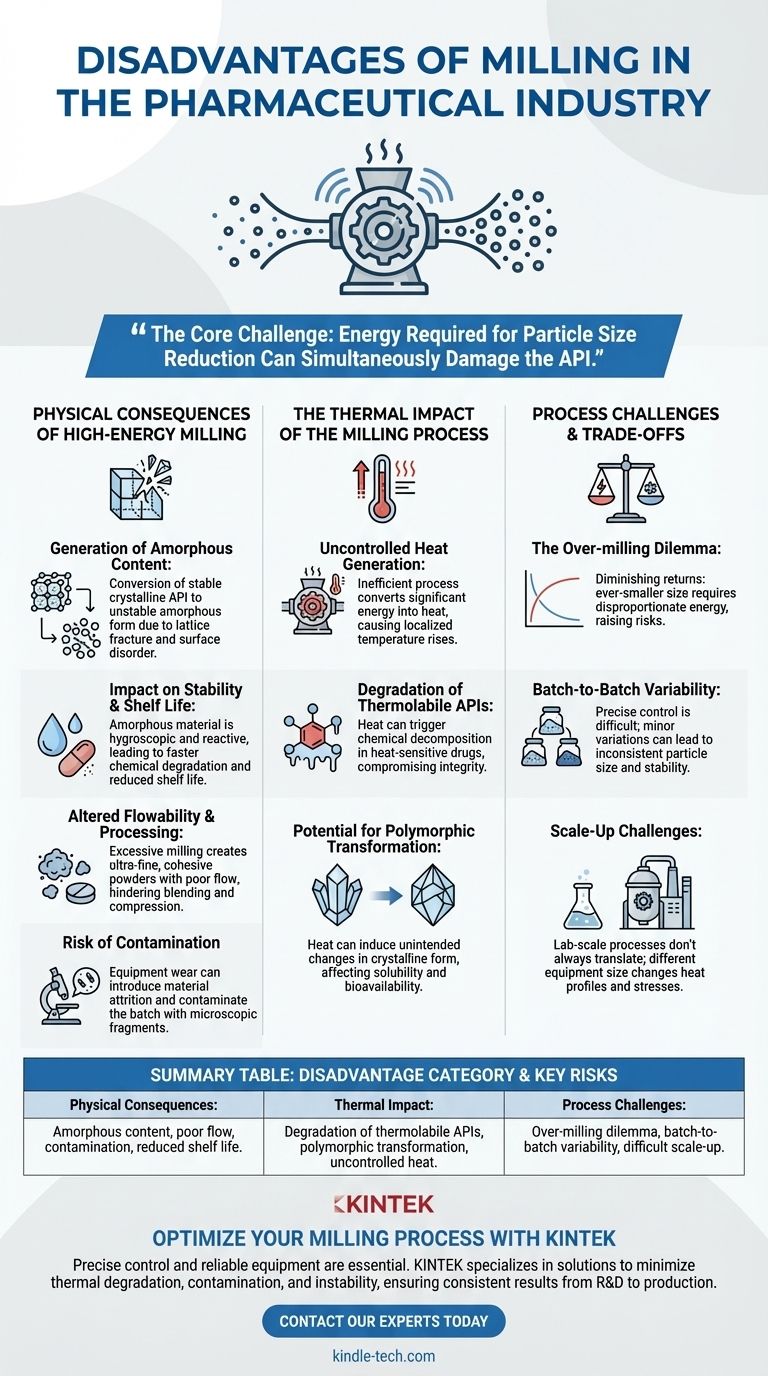

While essential for controlling particle size, pharmaceutical milling is a high-energy process that can introduce significant, often undesirable, changes to the drug substance. The primary disadvantages stem from the intense mechanical and thermal stress applied to the material, which can lead to physical instability, chemical degradation, and challenges in downstream processing.

The core challenge of milling is that the very energy required to reduce particle size can simultaneously damage the Active Pharmaceutical Ingredient (API). This creates a fundamental trade-off between achieving the desired physical properties and preserving the material's stability and integrity.

The Physical Consequences of High-Energy Milling

Milling physically breaks down particles, but this mechanical force has effects that go beyond simple size reduction. These changes can fundamentally alter the drug's behavior.

Generation of Amorphous Content

The most significant risk is the conversion of a stable crystalline API into a physically unstable amorphous form. The high energy input can fracture the ordered crystal lattice, creating disordered regions on the particle surface.

Impact on Stability and Shelf Life

Amorphous material is more reactive and has a higher affinity for water (hygroscopicity). This can lead to faster chemical degradation, reduced potency, and ultimately, a shorter shelf life for the final drug product.

Altered Flowability and Processing

While smaller particles are often desired, excessive milling can create ultra-fine powders with poor flow properties. These particles tend to agglomerate due to electrostatic forces, making subsequent steps like blending and tablet compression difficult and inconsistent.

Risk of Contamination

The milling process involves contact between the product and the milling equipment (e.g., grinding media, chamber walls). This can lead to material attrition, where microscopic fragments of the equipment contaminate the batch, a serious concern for product purity.

The Thermal Impact of the Milling Process

All the energy put into the milling system doesn't just break particles; a significant portion is converted into heat. This thermal stress is a major source of product degradation.

Uncontrolled Heat Generation

Milling is an inefficient process that generates substantial heat. Without proper cooling, localized temperatures can rise dramatically, even for short periods.

Degradation of Thermolabile APIs

This generated heat is especially dangerous for thermolabile (heat-sensitive) drugs. The temperature increase can be enough to trigger chemical decomposition, directly compromising the API's integrity and safety.

Potential for Polymorphic Transformation

For many APIs, heat can induce a change from one crystalline form to another, a phenomenon known as polymorphic transformation. Since different polymorphs can have vastly different solubility and bioavailability, an unintended transformation can render the drug ineffective or unpredictable.

Understanding the Trade-offs and Common Pitfalls

Successfully implementing a milling strategy requires a deep understanding of its inherent compromises and the challenges it presents.

The Over-milling Dilemma

There is a point of diminishing returns. Attempting to achieve an ever-smaller particle size often requires a disproportionate increase in energy, exponentially raising the risk of amorphization, thermal degradation, and contamination.

Batch-to-Batch Variability

Precisely controlling the milling process to produce identical results every time is challenging. Minor variations in material properties, equipment wear, or environmental conditions can lead to inconsistencies in particle size distribution and physical stability between batches.

Scale-Up Challenges

A process that works perfectly at the laboratory scale may not translate directly to full-scale production. The physics of milling changes with equipment size, often leading to different heat profiles and mechanical stresses that require extensive redevelopment and validation.

Making the Right Choice for Your Goal

Evaluating the disadvantages of milling is crucial for developing a robust and reliable manufacturing process. Your approach should be tailored to the specific properties of your API.

- If your primary focus is on a highly crystalline and stable API: Your goal is to optimize milling parameters (e.g., duration, intensity, temperature control) to minimize contamination and amorphization.

- If your primary focus is on a thermolabile or amorphous-prone API: You should strongly consider alternative or modified technologies like cryogenic milling or co-milling with excipients to protect the molecule from damage.

- If your primary focus is on downstream processability: You must balance the need for small particle size against the risk of poor powder flow, potentially requiring post-milling formulation adjustments.

Ultimately, viewing milling not just as a size-reduction step but as a critical process that can alter your material's fundamental properties is key to successful drug formulation.

Summary Table:

| Disadvantage Category | Key Risks & Impacts |

|---|---|

| Physical Consequences | Amorphous content generation, poor flowability, batch contamination, reduced shelf life |

| Thermal Impact | Degradation of thermolabile APIs, polymorphic transformation, uncontrolled heat generation |

| Process Challenges | Over-milling dilemma, batch-to-batch variability, difficult scale-up |

Optimize Your Milling Process with KINTEK

Navigating the complexities of pharmaceutical milling requires precise control and reliable equipment to protect your API's integrity. KINTEK specializes in advanced lab equipment and consumables designed to minimize thermal degradation, contamination, and instability risks.

We provide solutions tailored to your specific needs—whether you're working with heat-sensitive compounds or scaling up from R&D to production. Our expertise helps you achieve consistent particle size reduction while preserving your product's quality and stability.

Ready to enhance your milling process? Contact our experts today to discuss your challenges and discover how KINTEK can support your laboratory's success.

Visual Guide

Related Products

- Laboratory Single Horizontal Jar Mill

- Single Punch Tablet Press Machine and Mass Production Rotary Tablet Punching Machine for TDP

- Laboratory Planetary Ball Mill Rotating Ball Milling Machine

- Laboratory Horizontal Planetary Ball Mill Milling Machine

- Small Injection Molding Machine for Lab Use

People Also Ask

- What is the product size achieved by hammer mill? Control Your Grind with Screen Size & Speed

- What is the function of an agate mortar in CoFe2O4 synthesis? Achieve Ultra-Pure & Homogeneous Powder Processing

- What is the function of a laboratory grinding mill? Achieve Precise Sample Preparation for Accurate Results

- What size is a lab mixing mill? A Guide to Matching Capacity to Your Application

- What is the role of homogenization in C-S-H synthesis? Achieve Phase-Pure Calcium Silicate Hydrate Consistency

- What is the primary function of mechanical grinding equipment in the physical modification of lignin?

- What are the different types of milling in pharma? A Guide to Wet vs. Dry Milling Techniques

- Why is it necessary to crush or grind the samples? Ensure Accurate & Reliable Lab Analysis