While a foundational tool in particle analysis, the mechanical sieve shaker is not a universal solution. Its primary disadvantages emerge when analyzing very fine powders or irregularly shaped particles, leading to significant inaccuracies if the method is misapplied. The core issues stem from the physical assumptions inherent in its design.

The fundamental limitation of sieve analysis is that it measures a particle's ability to pass through a square hole. This geometric sorting method breaks down when a particle's shape, size, or intermolecular forces prevent it from behaving like a simple, free-flowing sphere.

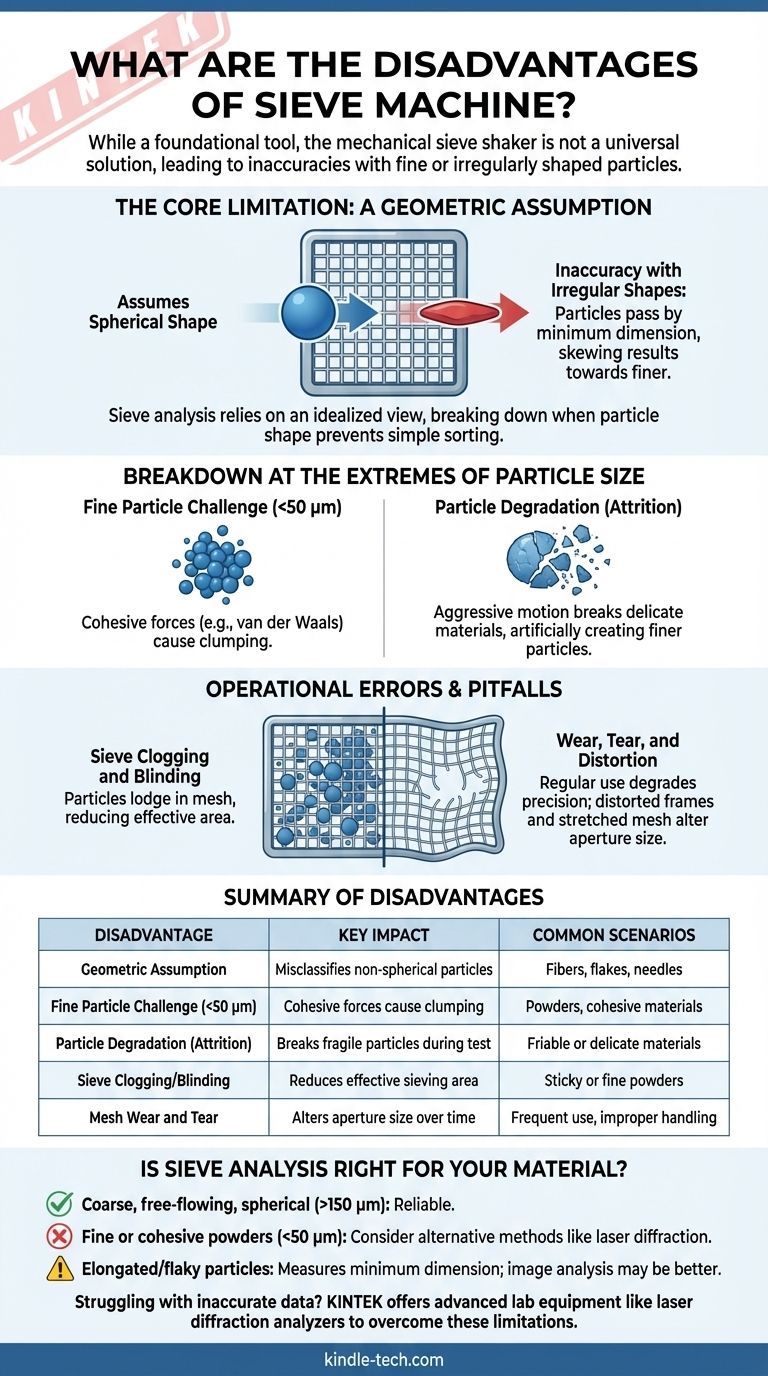

The Core Limitation: A Geometric Assumption

Sieve analysis is a purely mechanical process that sorts particles based on their dimensions. This simplicity is also its greatest weakness, as it relies on an idealized view of how particles behave.

The "Perfect Sphere" Problem

The entire method assumes that particles are roughly spherical. The square mesh openings are designed to stop spheres above a certain diameter while letting smaller ones pass through.

Inaccuracy with Irregular Shapes

Real-world particles are rarely perfect spheres. Elongated, flat, or needle-like particles present a major challenge.

These particles can pass through the mesh end-on or diagonally, meaning they are classified by their second-largest or smallest dimension, not their true length or volume. This leads to mass-based results that incorrectly suggest the material is finer than it actually is.

Breakdown at the Extremes of Particle Size

The effectiveness of a sieve shaker deteriorates significantly when particles are either too small or too fragile.

The Fine Particle Challenge (< 50 µm)

For materials finer than about 100 mesh (approximately 150 µm), and especially below 50 µm, sieving becomes highly unreliable.

At this scale, inter-particle cohesive forces (like van der Waals and electrostatic forces) can be stronger than the gravitational and kinetic forces applied by the shaker. Particles clump together, failing to pass through openings they would easily fit through individually.

Risk of Particle Degradation (Attrition)

The aggressive shaking motion required for separation can damage delicate or friable materials.

This process, known as attrition, breaks down larger particles into smaller ones during the test itself. This artificially skews the particle size distribution toward the finer end, creating inaccurate data.

Understanding the Trade-offs and Pitfalls

Beyond its theoretical limits, sieve analysis is prone to operational errors that can compromise results if not carefully managed.

Sieve Clogging and Blinding

This is one of the most common practical failures. Clogging (or blinding) occurs when particles become lodged in the mesh openings, reducing the effective sieving area and preventing other particles from passing through.

Fine powders can also coat the mesh wires, effectively shrinking the apertures and skewing the results.

Wear, Tear, and Distortion

Sieves are precision instruments that degrade with use. Over time, the wire mesh can stretch, sag, or even break, altering the size of the apertures.

Dropping a sieve or improper handling can distort the frame, rendering it useless for accurate analysis. Regular inspection and calibration are critical.

Is Sieve Analysis Right for Your Material?

Choosing the correct analysis method requires understanding these limitations. Your decision should be based on the specific characteristics of your material and your analytical goals.

- If your primary focus is on coarse, free-flowing, and relatively spherical materials (> 150 µm): Sieve analysis is a highly reliable, straightforward, and cost-effective method.

- If your primary focus is on fine or cohesive powders (< 50 µm): You must consider alternative methods like laser diffraction, which are not limited by cohesive forces.

- If your primary focus is on elongated or flaky particles (e.g., fibers, granules): Be aware that sieving will only measure their minimum dimension; image analysis may provide a more comprehensive characterization.

Recognizing the limitations of your tools is the first step toward generating particle analysis data you can truly trust.

Summary Table:

| Disadvantage | Key Impact | Common Scenarios |

|---|---|---|

| Geometric Assumption | Misclassifies non-spherical particles | Fibers, flakes, needles |

| Fine Particle Challenge (< 50 µm) | Cohesive forces cause clumping | Powders, cohesive materials |

| Particle Degradation (Attrition) | Breaks fragile particles during test | Friable or delicate materials |

| Sieve Clogging/Blinding | Reduces effective sieving area | Sticky or fine powders |

| Mesh Wear and Tear | Alters aperture size over time | Frequent use, improper handling |

Struggling with inaccurate particle size data? Your material may require a more advanced analytical technique. KINTEK specializes in lab equipment and consumables, offering solutions like laser diffraction analyzers that overcome the limitations of traditional sieve shakers. Our experts can help you select the right instrument for accurate characterization of fine powders, cohesive materials, and irregularly shaped particles. Contact our team today to discuss your specific application and ensure reliable, trustworthy results for your laboratory.

Visual Guide

Related Products

- Laboratory Vibratory Sieve Shaker Machine for Dry and Wet Three-Dimensional Sieving

- Laboratory Test Sieves and Vibratory Sieve Shaker Machine

- Laboratory Vibratory Sieve Shaker Machine Slap Vibrating Sieve

- Three-dimensional electromagnetic sieving instrument

- Vibratory Sieve Shaker Machine Dry Three-Dimensional Vibrating Sieve

People Also Ask

- How do laboratory constant temperature shakers ensure material uniformity? Optimize Bimetallic Nanocatalyst Synthesis

- What are the different types of sieving? Dry vs. Wet Methods for Accurate Particle Analysis

- What is the function of a benchtop mild shaker? Optimize Plasmonic Cellulose Paper Deposition with KINTEK Shakers

- What are sieve shakers used for? Achieve Reliable Particle Size Analysis

- How do industrial-grade sieving systems facilitate the adjustment of chromium powder combustion performance?

- How do crushing and sieving systems facilitate bioactive extraction? Boost Yield in Tilia cordata Research

- What are the apparatus used for sieve analysis? Build a Reliable Particle Sizing System

- Which technique is best for the determination of particle size? Match Your Material to the Right Method