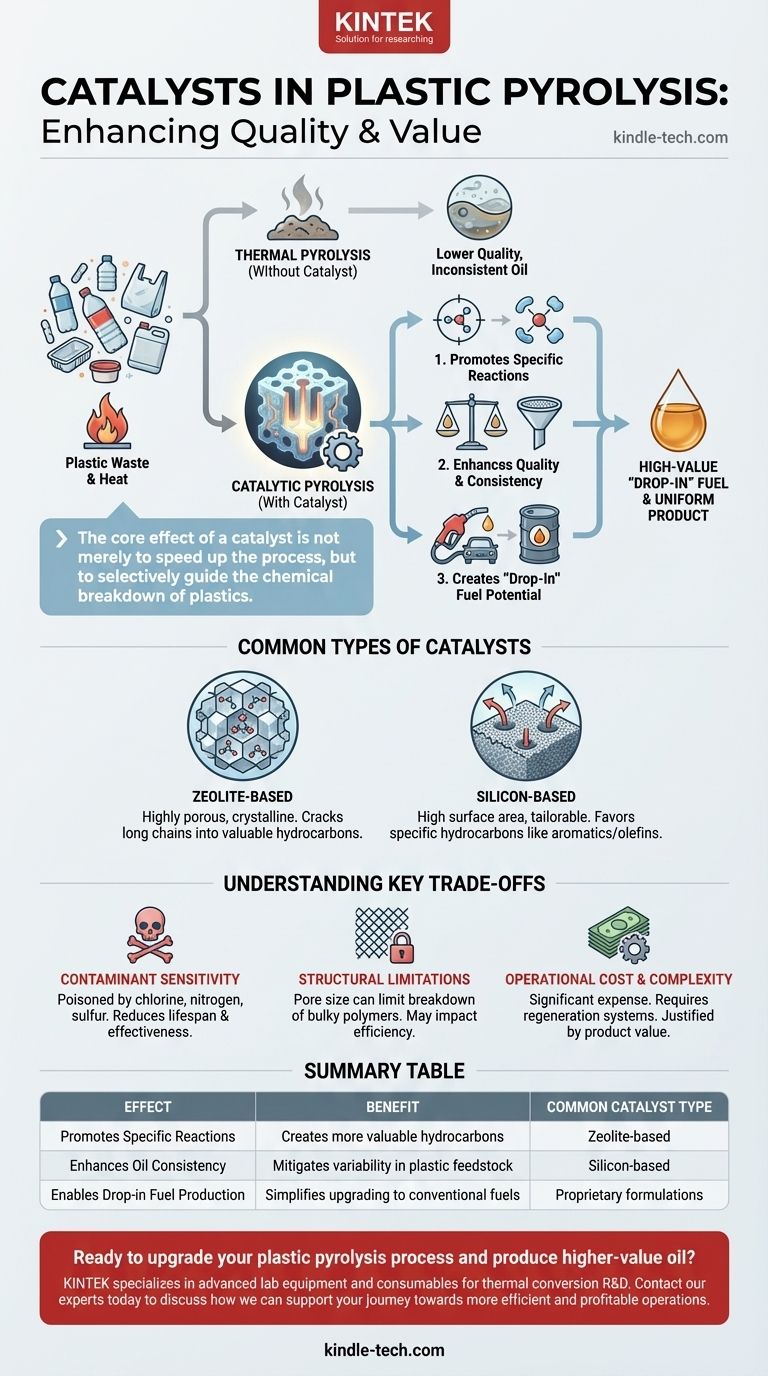

In plastic pyrolysis, a catalyst fundamentally improves the final product quality. Its primary role is to promote specific chemical reactions that convert the raw plastic waste into a higher-value oil. This catalytic action results in a product that is more uniform and easier to upgrade into "drop-in" fuels, which are chemically similar to conventional hydrocarbon fuels.

The core effect of a catalyst is not merely to speed up the process, but to selectively guide the chemical breakdown of plastics. This produces a more consistent and valuable oil, even when dealing with variable quality in the raw plastic feedstock.

How Catalysts Alter the Pyrolysis Process

A catalyst acts as a chemical intermediary, creating a more efficient pathway for the desired reactions to occur during the intense heat of pyrolysis. This targeted intervention is what separates basic pyrolysis from a more refined conversion process.

Promoting Specific Chemical Reactions

Without a catalyst, pyrolysis is a blunt thermal decomposition process. A catalyst introduces precision, encouraging the long polymer chains in plastic to break down into more specific, desirable molecules. It directs the process towards creating valuable hydrocarbons.

Enhancing Oil Quality and Consistency

Plastic waste is notoriously inconsistent, with variations in composition, moisture, and non-plastic contaminants. Catalysts help mitigate this inconsistency by promoting a more uniform output. Technologies like Pyrolysis Oil Purification, often used in conjunction with catalysts, further ensure a consistent oil quality despite variations in the raw material.

Creating "Drop-In" Fuel Potential

The ultimate goal for many operations is to produce fuel. Catalysts are critical for creating an oil that contains molecules found in current hydrocarbon fuels. This makes the subsequent upgrading and refining process simpler and more economically viable.

Common Types of Catalysts

While many catalysts are proprietary, several classes are widely used in thermal and catalytic conversion processes. Their physical structure is as important as their chemical composition.

Zeolite-Based Catalysts

Zeolites are highly porous materials with a well-defined, crystalline structure. Their pores act as microscopic reaction chambers, selectively allowing certain molecules to form. They are highly effective at cracking long hydrocarbon chains into smaller, more valuable ones.

Silicon-Based Catalysts

Catalysts based on silicon, often in the form of silica-alumina, are also common. They provide a high surface area for reactions to occur and can be tailored to favor the production of specific types of hydrocarbons, such as aromatics or olefins.

Understanding the Key Trade-offs

Introducing a catalyst is not a simple upgrade; it involves a new set of operational challenges and economic considerations that must be carefully managed.

Sensitivity to Contaminants

Catalysts can be "poisoned" or deactivated by contaminants common in plastic waste streams, such as chlorine from PVC, nitrogen, or sulfur. This reduces their effectiveness and lifespan, requiring more frequent regeneration or replacement.

Structural Limitations

The effectiveness of a catalyst is often linked to its physical structure, like its pore size. While highly effective, some commercial catalysts like zeolites can face challenges with the very large, complex polymers found in certain types of waste. Their narrow pores, ideal for petrochemicals, may not be perfectly suited for breaking down bulkier materials, impacting efficiency.

Operational Cost and Complexity

High-performance catalysts are a significant operational expense. The need for catalyst regeneration systems and the cost of replacement adds complexity and financial outlay to the pyrolysis plant. This investment must be justified by the increased value and consistency of the final oil product.

How to Apply This to Your Operation

Choosing to use a catalyst—and which one—depends entirely on your end-product goals and the nature of your feedstock.

- If your primary focus is producing the highest-quality synthetic crude for refining: A selective catalyst, likely zeolite-based, is essential to create a consistent, high-value product.

- If your primary focus is processing highly mixed and contaminated plastic waste: You may need a more robust, lower-cost catalyst or a multi-stage process that includes pre-treatment to protect the catalyst.

- If your primary focus is maximizing liquid yield without stringent quality demands: A non-catalytic thermal pyrolysis process might be the most economically straightforward option.

Ultimately, integrating a catalyst transforms pyrolysis from simple decomposition into a targeted chemical conversion process.

Summary Table:

| Effect | Benefit | Common Catalyst Type |

|---|---|---|

| Promotes Specific Reactions | Creates more valuable hydrocarbons | Zeolite-based |

| Enhances Oil Consistency | Mitigates variability in plastic feedstock | Silicon-based |

| Enables Drop-in Fuel Production | Simplifies upgrading to conventional fuels | Proprietary formulations |

Ready to upgrade your plastic pyrolysis process and produce higher-value oil? KINTEK specializes in advanced lab equipment and consumables for thermal conversion research and development. Our expertise can help you select and test the right catalyst for your specific plastic feedstock and end-product goals. Contact our experts today to discuss how we can support your journey towards more efficient and profitable pyrolysis operations.

Visual Guide

Related Products

- Custom PTFE Teflon Parts Manufacturer for PTFE Mesh F4 Sieve

- Custom PTFE Teflon Parts Manufacturer for PTFE Buchner Funnel and Triangular Funnel

- Custom PTFE Teflon Parts Manufacturer for PTFE Measuring Cylinder 10/50/100ml

- Custom PTFE Teflon Parts Manufacturer for Culture Dish and Evaporation Dish

- Advanced Engineering Fine Ceramics Boron Nitride (BN) Ceramic Parts

People Also Ask

- What are the specific applications of PTFE in micro-batch slug flow systems? Enhance Your Microfluidic Reaction Purity

- What is the impact factor of powder metallurgy progress? A 2022 Analysis & Context

- Why is PTFE wire used for hanging metal specimens in biodiesel corrosion tests? Ensure Pure Experimental Results

- What are alloys in simple words? Unlock the Power of Engineered Materials

- What is the difference between PPF and coating? Armor vs. Slick Shell for Your Car