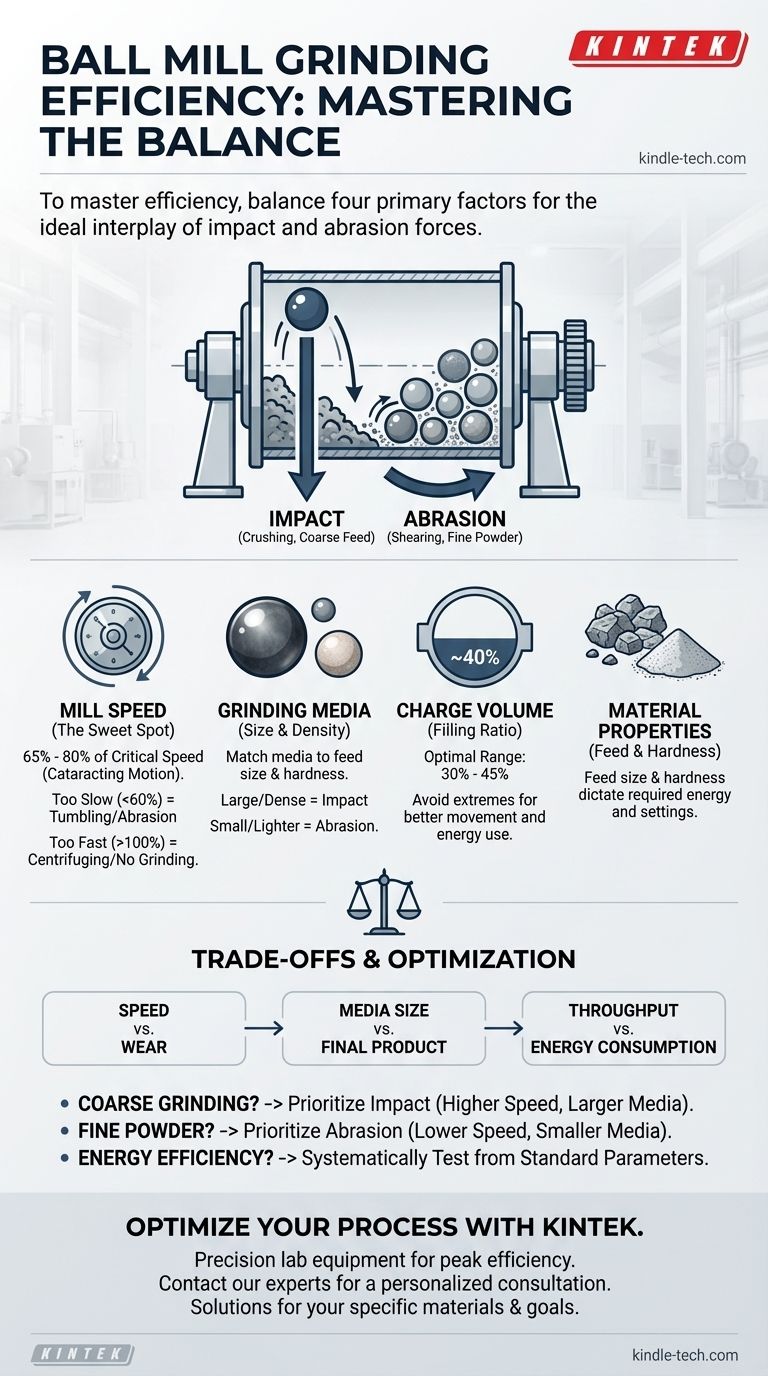

To master ball mill efficiency, you must understand the interplay of four primary factors: the rotational speed of the mill, the properties of the grinding media (its size and type), the characteristics of the material being ground, and the volume of the mill occupied by the grinding media, also known as the filling ratio. Each of these variables directly controls the forces inside the mill, determining the final product and the energy consumed.

The core principle of ball mill optimization is not about maximizing any single factor, but about achieving a precise balance. The goal is to create the ideal combination of impact and abrasion forces required for your specific material and desired particle size.

The Mechanics of Grinding: Impact vs. Abrasion

To control efficiency, you must first understand the two fundamental actions that occur inside a ball mill. Every factor you adjust is meant to influence the balance between these two forces.

The Role of Impact

Impact is the crushing force that results from grinding media falling from the highest point of its rotation. This high-energy collision is essential for breaking down large, coarse feed particles into smaller pieces.

The Role of Abrasion

Abrasion is the shearing or rubbing force that occurs as media tumbles and slides against each other and the material. This action is responsible for grinding smaller particles into a very fine powder.

Critical Factors Influencing Efficiency

Optimizing your process requires a methodical approach to adjusting the key operational parameters. Each one has a distinct effect on the balance between impact and abrasion.

Mill Speed (The Critical Speed Threshold)

The rotational speed of the mill is arguably the most influential variable. It is typically discussed in relation to its "critical speed"—the theoretical speed at which centrifugal force would cause the grinding media to pin against the mill wall.

- Too Slow: At very low speeds (below 60% of critical speed), the media simply tumbles and cascades down, resulting in low impact and primarily abrasive grinding. This is inefficient for breaking coarse material.

- Too Fast: As speed approaches or exceeds the critical speed, the media is thrown against the liner and held there by centrifugal force. This is known as "centrifuging," and virtually no grinding occurs.

- The Sweet Spot: Optimal efficiency is usually found between 65% and 80% of critical speed. In this range, the media is lifted high enough to create a "cataracting" motion, maximizing impact forces without centrifuging, leading to an effective blend of impact and abrasion.

Grinding Media Characteristics

The grinding media—the balls themselves—are the instruments of size reduction. Their size, shape, and density are critical.

- Media Size: The size of the media should be proportional to the size of the feed material. Large, heavy balls are needed to generate the impact energy required to break large particles. Smaller balls have more surface area and are better for fine grinding via abrasion.

- Media Material & Density: Denser media, like forged steel, provides significantly more impact energy than lighter media, such as ceramic. The choice depends on the hardness of the material being ground and any contamination concerns.

Mill Charge Volume (Filling Ratio)

This refers to the percentage of the mill's internal volume filled by the grinding media when at rest.

The typical charge volume is between 30% and 45%. A low charge reduces the number of grinding events and is inefficient. An excessively high charge restricts the movement of the media, dampens impact forces, and wastes energy by needlessly lifting excess weight.

Material Properties

The nature of the material you are grinding dictates every other choice you make.

- Feed Size: The feed particles must be small enough for the chosen grinding media to effectively capture and break them.

- Hardness and Toughness: Harder materials require greater impact forces to fracture, necessitating denser, larger media and a speed that favors cataracting motion.

Understanding the Trade-offs

Pursuing one performance metric often comes at the expense of another. Recognizing these trade-offs is key to a truly optimized and cost-effective operation.

Speed vs. Wear

Increasing mill speed can boost throughput, but it also dramatically accelerates the rate of wear on both the grinding media and the mill liners. This is a direct trade-off between production rate and operational cost.

Media Size vs. Final Product

Using large media is effective for breaking coarse feed but is highly inefficient for producing very fine powders. Conversely, using small media to grind large feed material will result in slow production rates and wasted energy. A graded charge of multiple sizes is often used to balance this.

Throughput vs. Energy Consumption

Pushing a mill for the maximum possible throughput by increasing the feed rate often leads to a less-efficient grind. This results in a higher energy consumption (kWh) per ton of finished product, as material may pass through too quickly without achieving the target particle size.

Making the Right Choice for Your Goal

Your operational settings should be a direct reflection of your primary objective. Use these principles as a starting point for process optimization.

- If your primary focus is coarse grinding (primary size reduction): Prioritize impact forces by using larger, denser media and operating the mill in the higher end of the optimal speed range (75-80% of critical) to encourage cataracting.

- If your primary focus is producing a fine powder: Prioritize abrasion by using smaller media to maximize surface area contact and a slightly lower speed (65-70% of critical) that promotes cascading and tumbling.

- If your primary focus is maximizing energy efficiency: Begin with standard parameters (e.g., 40% charge, 75% speed) and systematically test small adjustments to find the lowest energy draw that still achieves your required particle size and throughput.

Ultimately, achieving peak ball mill efficiency is a process of balancing these interconnected variables to create the ideal grinding environment for your specific application.

Summary Table:

| Factor | Key Influence on Efficiency | Optimal Range/Consideration |

|---|---|---|

| Mill Speed | Balances impact vs. abrasion forces | 65% - 80% of critical speed |

| Grinding Media | Size and density dictate breakage mechanism | Match size to feed; denser media for harder materials |

| Material Properties | Hardness and feed size dictate required energy | Smaller feed for efficient grinding |

| Charge Volume (Filling Ratio) | Affects media movement and energy use | Typically 30% - 45% of mill volume |

Optimize Your Milling Process with KINTEK

Struggling to balance throughput, particle size, and energy consumption in your lab? KINTEK specializes in precision lab equipment, including ball mills and grinding media, to help you achieve peak efficiency. Our experts can help you select the right configuration for your specific materials and goals, saving you time and reducing operational costs.

Contact our technical team today for a personalized consultation and discover how our solutions can enhance your laboratory's productivity and results.

Visual Guide

Related Products

- Mini Planetary Ball Mill Machine for Laboratory Milling

- High Energy Planetary Ball Mill Machine for Laboratory Horizontal Tank Type

- Liquid Nitrogen Cryogenic Grinder Mill Cryomill Airflow Ultrafine Pulverizer

- Small Injection Molding Machine for Lab Use

- Double Plate Heating Press Mold for Lab

People Also Ask

- What are the unique energy transfer characteristics of PBM? Master Complex Heterocyclic Synthesis

- What is the role of a planetary ball mill in sulfide-based solid-state batteries? Engineer High-Performance Cathodes

- What is the specific role of a planetary ball mill in preparing LPS sulfide electrolytes? Unlock Superior Conductivity

- How does a planetary ball mill demonstrate process versatility? Powering NaNbOCl4 and NaTaOCl4 Synthesis

- How does a planetary ball mill enhance the electrocatalytic activity of La0.6Sr0.4CoO3-δ? Boost Your Catalyst Performance