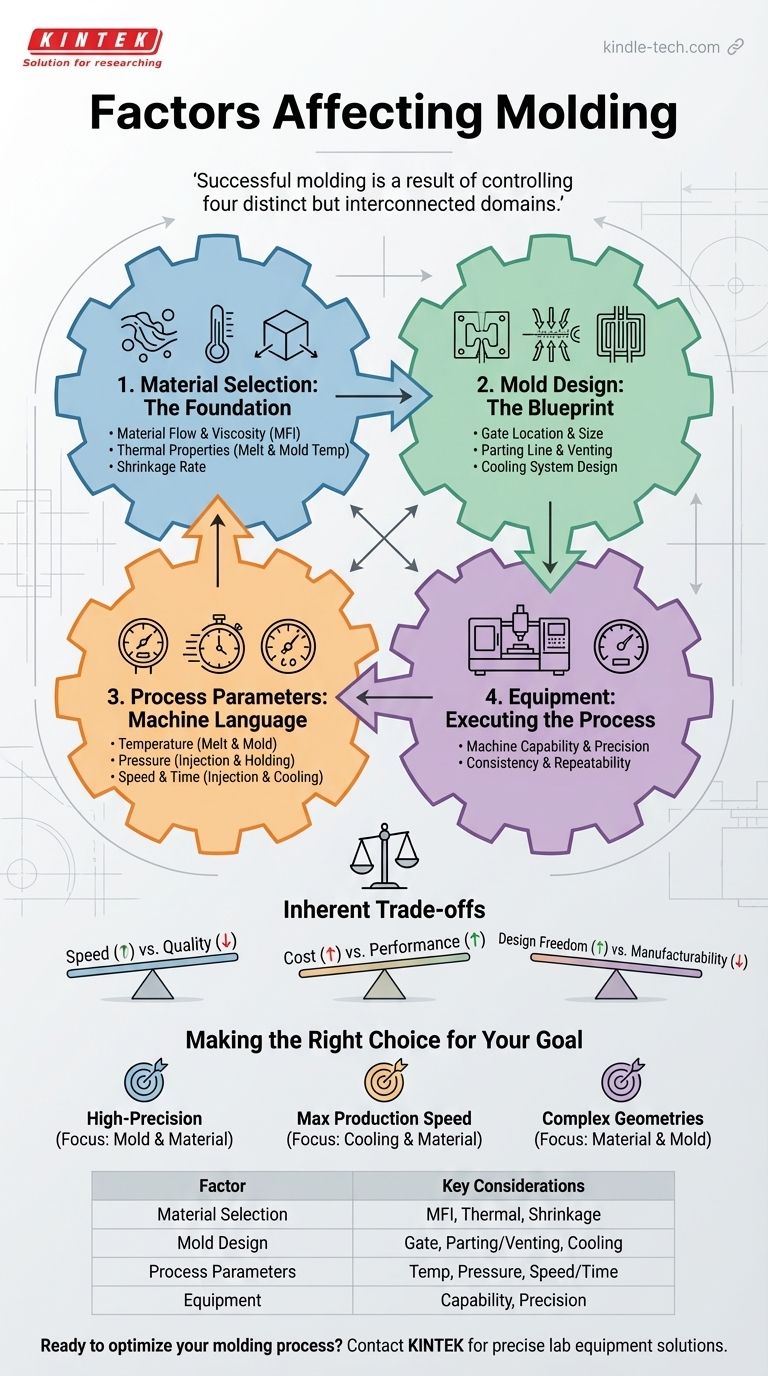

At its core, successful molding is a result of controlling four distinct but interconnected domains. The critical factors that determine the quality, consistency, and cost-effectiveness of a molded part are the material properties, the design of the mold itself, the process parameters used during the cycle, and the equipment executing the process.

The quality of a final molded part is never determined by a single variable. It is the result of a precise and balanced interaction between the chosen material, the physical design of the tool, and the specific pressures, temperatures, and times used during the manufacturing cycle.

1. Material Selection: The Foundation of the Part

The raw material is the starting point that dictates the potential and limitations of the final product. Its properties influence both the molding process and the part's end-use performance.

Material Flow and Viscosity

The melt flow index (MFI) or viscosity of a polymer determines how easily it flows into the mold cavity. High-flow materials fill complex, thin-walled parts more easily but can be more prone to flashing (leaking out of the mold).

Thermal Properties

Melt temperature dictates the energy required to make the material flow, while mold temperature affects surface finish and cooling time. The material's thermal stability is critical to prevent degradation from excessive heat or time in the barrel.

Shrinkage Rate

Every plastic shrinks as it cools from a molten to a solid state. This shrinkage rate, which varies significantly between materials, must be accounted for in the mold design to achieve final part-dimensional accuracy.

2. Mold Design: The Blueprint for Quality

The mold is the physical tool that shapes the material. Its design is arguably the most critical factor for preventing defects and ensuring efficient production.

Gate Location and Size

The gate is the entry point for the molten plastic into the cavity. Its location and size are critical for controlling flow patterns, minimizing cosmetic defects like jetting, and determining where weld lines (where two flow fronts meet) will form.

Parting Line and Venting

The parting line is where the two halves of the mold meet. Improper seating can cause flash. Vents are microscopic channels that allow trapped air and gas to escape the cavity as it fills. Inadequate venting leads to incomplete parts (short shots) or burn marks.

Cooling System Design

The layout of cooling channels within the mold directly controls the rate and uniformity of cooling. An inefficient or unbalanced cooling system is a primary cause of part warpage and unnecessarily long cycle times.

3. Process Parameters: The Language of the Machine

These are the variables set on the molding machine for each cycle. They must be optimized for the specific combination of material and mold design.

Temperature

There are two key temperatures: melt temperature (the temperature of the plastic as it's injected) and mold temperature (the surface temperature of the cavity). These must be in the correct balance to ensure proper flow, good surface finish, and minimal internal stress.

Pressure

Injection pressure forces the material into the mold. This is followed by holding pressure (or "packing pressure"), which compensates for material shrinkage as it begins to cool, preventing sink marks and voids.

Speed and Time

Injection speed affects how quickly the mold fills, influencing both surface appearance and internal stresses. Cooling time, often the largest portion of the cycle, is determined by the material, part thickness, and mold temperature.

Understanding the Inherent Trade-offs

Optimizing a molding process is always a balancing act. Understanding these compromises is key to making informed decisions.

Speed vs. Quality

Increasing injection speed or reducing cooling time can shorten the overall cycle time and lower costs. However, this often comes at the price of increased defects such as flash, internal stress, warpage, or sink marks.

Cost vs. Performance

High-performance polymers and complex molds with features like slides or hot runners deliver superior parts but come with a significant upfront cost. Cheaper materials and simpler tools may be sufficient for less demanding applications but limit design freedom and part quality.

Design Freedom vs. Manufacturability

A designer may envision a complex part, but its geometry can create molding challenges. Features like sharp corners, extreme variations in wall thickness, or deep ribs can be difficult to fill and cool uniformly, requiring careful collaboration between designers and manufacturing engineers.

Making the Right Choice for Your Goal

The "correct" settings are entirely dependent on your primary objective. Use your goal to guide which factors you prioritize.

- If your primary focus is high-precision and tight tolerances: Prioritize a meticulously designed mold with precise cooling and select a material with a low, uniform shrinkage rate.

- If your primary focus is maximum production speed: Emphasize optimizing cooling time through efficient mold design and selecting a material that sets up quickly.

- If your primary focus is molding complex geometries: Concentrate on material selection (high-flow polymers) and advanced mold design, including strategic gate locations and robust venting.

Ultimately, mastering the molding process means understanding that every factor influences the others, requiring a holistic approach to achieve consistent, high-quality results.

Summary Table:

| Factor | Key Considerations |

|---|---|

| Material Selection | Melt flow index (MFI), thermal properties, shrinkage rate |

| Mold Design | Gate location/size, parting line, venting, cooling system |

| Process Parameters | Temperature (melt & mold), pressure (injection & holding), speed & time |

| Equipment | Machine capability, precision, and consistency |

Ready to optimize your molding process? The right lab equipment is fundamental for testing material properties, prototyping mold designs, and validating process parameters. KINTEK specializes in providing the precise lab equipment and consumables you need to master these critical factors. Whether you're developing new materials or refining production cycles, our solutions help you achieve consistent, high-quality results. Contact our experts today to discuss how we can support your laboratory and manufacturing goals.

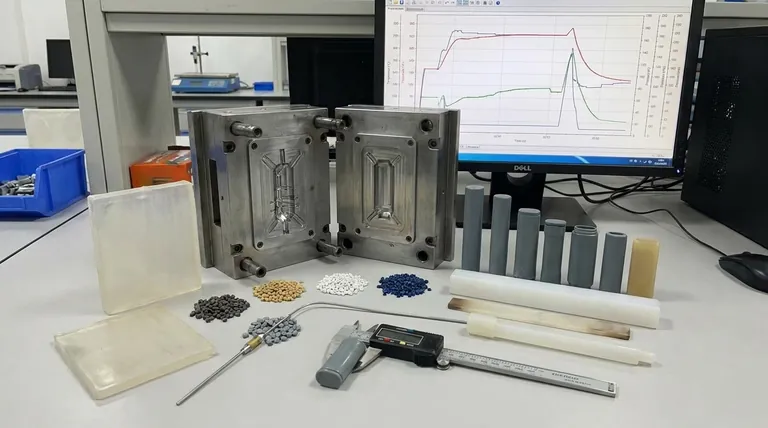

Visual Guide

Related Products

- Isostatic Molding Pressing Molds for Lab

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Aluminum Foil Current Collector for Lithium Battery

- Laboratory Disc Rotary Mixer for Efficient Sample Mixing and Homogenization

- Vacuum Cold Trap Direct Cold Trap Chiller

People Also Ask

- What role does a graphite mold play in vacuum hot-pressing graphene/alumina ceramics? Boost Sintering Precision

- What is cold isostatic pressing mold material? Essential Elastomers for Uniform Density

- What is the role of high-purity graphite molds in vacuum hot pressing? Enhance Diamond Composite Matrix Precision

- How should KBr powder be pre-treated before it is used to make a pellet? Optimize Your FTIR Spectra Quality

- What are the disadvantages of three plate mould? Higher Costs, Complexity & Maintenance

- What are the critical performance requirements for hot pressing molds? Ensure Precision in Magnesium Alloy Processing

- What role do specialized pressure dies play in Cold Sintering multi-layer batteries? Ensure Flawless Device Integration

- Why is the use of high-strength graphite molds necessary when sintering NITE-SiC? Ensure Density and Precision