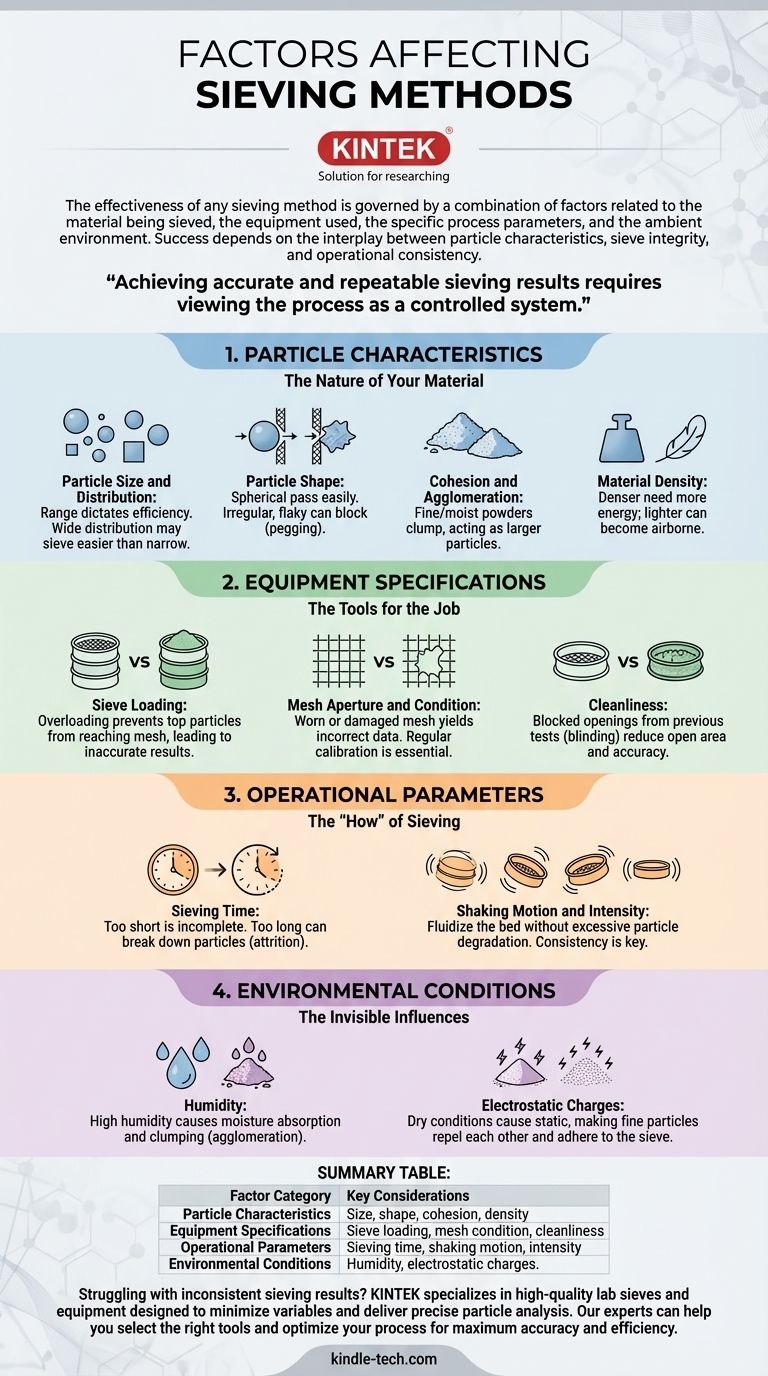

The effectiveness of any sieving method is governed by a combination of factors related to the material being sieved, the equipment used, the specific process parameters, and the ambient environment. For instance, environmental conditions like very low humidity can generate strong electrostatic charges, causing fine powders to adhere to the sieve and each other. Conversely, very high humidity can cause particles to clump, both of which prevent accurate separation.

Achieving accurate and repeatable sieving results requires viewing the process as a controlled system. Success depends less on a single variable and more on the interplay between particle characteristics, sieve integrity, and operational consistency.

1. Particle Characteristics: The Nature of Your Material

The physical properties of the particles you are analyzing are the most significant influence on the sieving process.

Particle Size and Distribution

The range of particle sizes in your sample dictates the efficiency of separation. A sample with a wide distribution may sieve more easily than one with many particles very close to the size of the sieve opening, which can cause blockages.

Particle Shape

Ideally shaped, spherical particles pass through sieve openings most easily. Irregular, elongated, or flaky particles present a major challenge, as they may only pass when oriented correctly or can get stuck in the mesh, a phenomenon known as pegging.

Cohesion and Agglomeration

Fine powders, especially those with moisture content or inherent stickiness, tend to agglomerate or form clumps. These clumps behave as larger particles, preventing the individual fine particles from passing through the mesh and skewing results.

Material Density

Denser particles require more energy (i.e., more vigorous shaking) to move freely and present themselves to the sieve openings. Lighter particles can become airborne within the sieve shaker, reducing their contact with the mesh.

2. Equipment Specifications: The Tools for the Job

The condition and specifications of your test sieves and shaker are critical for reliable outcomes.

Sieve Loading

Overloading a sieve is a common and critical error. A thick bed of material prevents particles at the top from ever reaching the mesh surface, leading to incomplete separation and inaccurate results.

Mesh Aperture and Condition

The precise size of the openings is fundamental. However, worn, damaged, or distorted mesh will yield incorrect data. Regular inspection and calibration of test sieves are essential for quality control.

Cleanliness

A sieve that has not been thoroughly cleaned will have blocked openings from previous tests. This blinding effectively reduces the available open area of the sieve, retaining particles that should have passed through.

3. Operational Parameters: The "How" of Sieving

How you conduct the sieving test directly impacts the results. These parameters must be kept consistent for repeatable analysis.

Sieving Time

Sieving for too short a time will result in incomplete separation. Extending the time indefinitely does not guarantee better results; it can lead to particle attrition, where particles break down from the mechanical action, artificially increasing the amount of fine material.

Shaking Motion and Intensity

The type of motion—vibratory, tapping, orbital, or ultrasonic—and its intensity are crucial. The goal is to fluidize the particle bed and give each particle the opportunity to pass through an aperture without causing excessive particle degradation.

4. Environmental Conditions: The Invisible Influences

The surrounding environment can introduce variables that are easy to overlook but can significantly impact results, especially with fine powders.

Humidity

As noted, high ambient humidity can introduce moisture to hygroscopic materials, causing them to become sticky and agglomerate. This prevents them from being sieved effectively.

Electrostatic Charges

Extremely dry conditions can lead to the buildup of static electricity. This causes fine particles to repel each other and adhere strongly to the sieve components, preventing them from passing through the mesh.

Making the Right Choice for Your Goal

To optimize your sieving process, you must control the variables most relevant to your objective.

- If your primary focus is analytical accuracy and repeatability: Standardize sieve loading, sieving time, and shaker intensity for every test.

- If your primary focus is working with fine powders (<100 microns): Actively monitor and control humidity, consider anti-static devices, or use wet sieving methods to overcome cohesion.

- If your primary focus is processing speed and throughput: Concentrate on preventing sieve blinding by selecting the right shaking motion and ensuring you do not overload the equipment.

By systematically controlling these factors, you transform sieving from a simple filtering task into a precise and reliable analytical method.

Summary Table:

| Factor Category | Key Considerations |

|---|---|

| Particle Characteristics | Size, shape, cohesion, density |

| Equipment Specifications | Sieve loading, mesh condition, cleanliness |

| Operational Parameters | Sieving time, shaking motion, intensity |

| Environmental Conditions | Humidity, electrostatic charges |

Struggling with inconsistent sieving results? KINTEK specializes in high-quality lab sieves and equipment designed to minimize variables and deliver precise particle analysis. Our experts can help you select the right tools and optimize your process for maximum accuracy and efficiency. Contact our team today to discuss your specific laboratory needs!

Visual Guide

Related Products

- Laboratory Test Sieves and Sieving Machines

- Laboratory Vibratory Sieve Shaker Machine Slap Vibrating Sieve

- Laboratory Single Horizontal Jar Mill

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- High Energy Vibratory Laboratory Ball Mill Grinding Mill Single Tank Type

People Also Ask

- What is the significance of using precision standard sieves for Inconel 625/TiB2? Optimize DLD Powder Quality

- What are the limitations of sieving method? Understanding Accuracy and Particle Size Challenges

- What are the sieve used in laboratory? A Guide to Choosing the Right Sieve for Accurate Particle Analysis

- What are the different methods of sieving? Choose the Right Technique for Your Material

- What is the primary function of fine-mesh test sieves? Master Natural Mordenite Purification

- What are the standard sieve sizes used in food industry? A Guide to ASTM, Tyler, and ISO Standards

- What were possible sources of error in sieve analysis? Avoid These Common Pitfalls for Accurate Results

- What are the advantages of the sieve method? Achieve Fast, Reliable Particle Size Analysis