The efficiency of a ball mill is not determined by a single setting, but by the precise interplay of several critical operational factors. These key variables include the mill's rotational speed, the characteristics of the grinding media (size and density), the properties of the material being processed, and the volume ratio of media to material within the mill chamber.

Grinding efficiency is fundamentally a balancing act. The goal is to maximize the energy transferred from the grinding media to the material, which requires optimizing mill speed to achieve the right impact-attrition balance while ensuring the media and material properties are correctly matched.

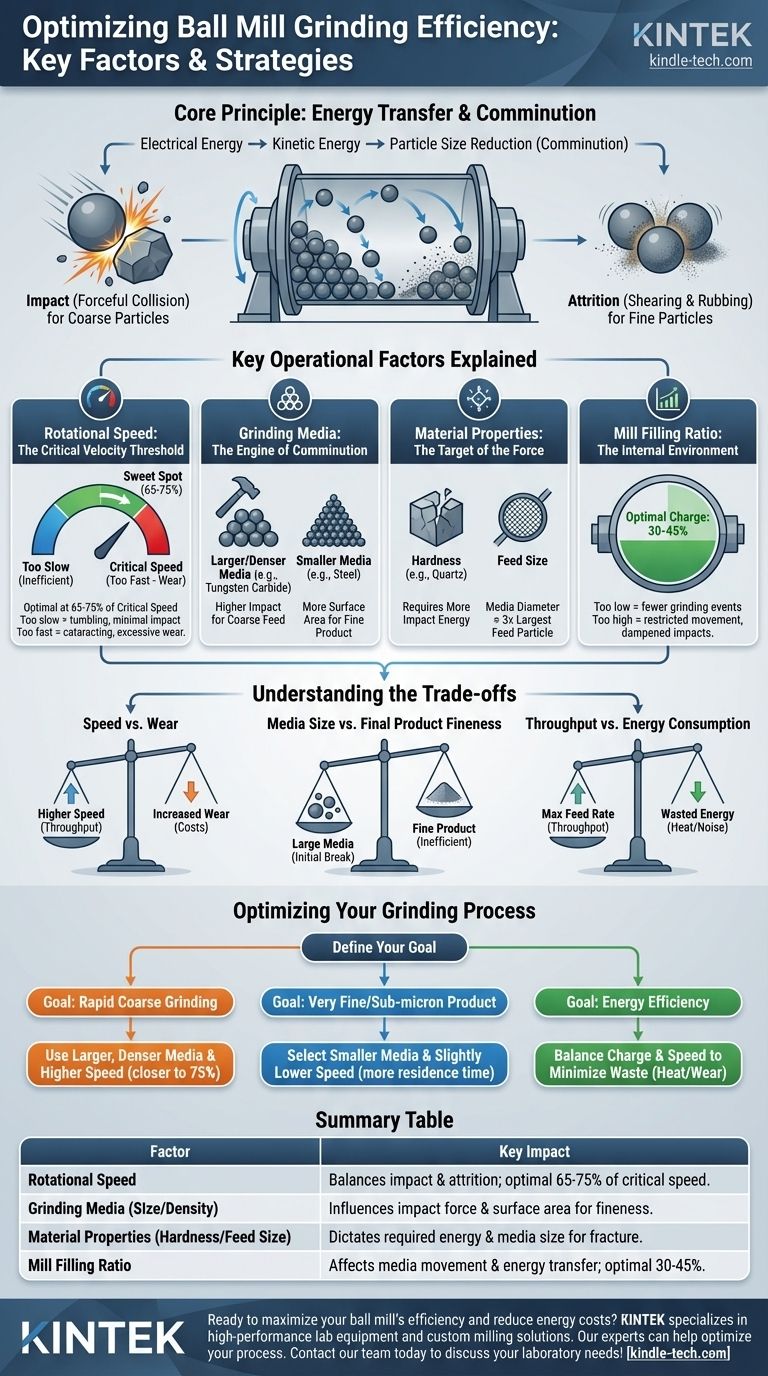

The Core Principle: Energy Transfer and Comminution

The entire purpose of a ball mill is to reduce the size of particles, a process known as comminution. This is achieved by converting electrical energy from a motor into kinetic energy within the mill.

From Rotation to Fracture

As the mill drum rotates, it lifts the grinding media (balls). This action imparts potential energy to the media. As the media reaches a certain height, it falls and cascades, converting that potential energy into the kinetic energy needed to crush and grind the target material.

Two Modes of Grinding

The energy transfer happens through two primary mechanisms.

- Impact: The forceful collision of falling balls against the material, which is effective for breaking down larger, coarse particles.

- Attrition: The shearing and rubbing action that occurs as balls tumble over one another, which is essential for grinding particles down to a very fine or even sub-micron size.

Key Operational Factors Explained

Optimizing the balance between impact and attrition requires careful control over several variables. Each factor directly influences how effectively energy is used to achieve the desired particle size.

Rotational Speed: The Critical Velocity Threshold

The speed of the mill is arguably the most critical factor. It is often discussed in relation to its "critical speed"—the theoretical speed at which the grinding media would centrifuge and cling to the mill's inner wall, halting all grinding action.

Operating at 65-75% of the critical speed is typically the sweet spot.

- Too slow: The media tumbles at the bottom of the mill, leading to inefficient, attrition-dominant grinding with minimal impact.

- Too fast: The media is thrown in a high arc, causing excessive wear on the mill liners with less effective grinding.

Grinding Media: The Engine of Comminution

The balls are the instruments of size reduction. Their characteristics must be matched to the task.

- Media Size: Larger media delivers higher impact force, ideal for breaking down coarse feed material. Smaller media provides a greater surface area and more contact points, promoting the attrition necessary for producing a fine product.

- Media Density: Denser media (like tungsten carbide or zirconia) transfers more energy upon impact than lighter media (like steel or alumina). This is crucial for grinding very hard materials.

Material Properties: The Target of the Force

The material being ground dictates the required approach.

- Hardness: Harder materials require more impact energy to fracture. This often means using denser grinding media or operating at a higher speed.

- Feed Size: The initial particle size of the feed material must be small enough for the chosen grinding media to effectively "nip" and break it. A common rule is that the media diameter should be roughly three times the size of the largest feed particles.

Mill Filling Ratio: The Internal Environment

The charge volume, or the percentage of the mill's internal volume filled with grinding media, is critical. A typical charge is between 30% and 45% of the mill volume.

- Too low: A low charge reduces the number of grinding events, decreasing efficiency and throughput.

- Too high: An overfilled mill restricts the movement of the media, dampening the cascading action and reducing the energy of impacts.

Understanding the Trade-offs

Pursuing one performance metric often comes at the expense of another. Recognizing these trade-offs is essential for practical optimization.

Speed vs. Wear

Increasing rotational speed can boost throughput, but it also dramatically accelerates the wear on both the grinding media and the mill's internal liners. This increases operational costs, maintenance downtime, and the risk of product contamination from worn components.

Media Size vs. Final Product Fineness

Using large media is highly effective for the initial breakdown of coarse material. However, it is an inefficient tool for producing very fine or sub-micron particles, as the large balls cannot effectively act on tiny particles. Achieving such fineness requires switching to smaller media.

Throughput vs. Energy Consumption

Maximizing the feed rate to increase throughput can lead to inefficient grinding if the mill cannot transfer energy effectively to the increased volume of material. This results in energy being wasted as heat and noise rather than being used for particle size reduction, driving up energy costs per unit of product.

Optimizing Your Grinding Process

Your ideal settings are dictated entirely by your end goal. The key is to align every operational factor with the desired outcome.

- If your primary focus is rapid coarse grinding: Use larger, denser grinding media and operate closer to the upper end of the optimal speed range (e.g., 75% of critical speed) to maximize impact forces.

- If your primary focus is achieving a very fine or sub-micron product: Select smaller grinding media to increase surface area contact and promote attrition, often at a slightly lower speed to ensure sufficient residence time.

- If your primary focus is energy efficiency: Carefully balance the mill charge and rotational speed to find the point where energy is directed into particle fracture, not wasted as excess heat or mechanical wear.

Ultimately, mastering ball mill efficiency comes from systematically tuning these variables to align with your specific material and desired particle size.

Summary Table:

| Factor | Key Impact on Grinding Efficiency |

|---|---|

| Rotational Speed | Determines the balance between impact & attrition; optimal at 65-75% of critical speed. |

| Grinding Media (Size/Density) | Influences impact force and surface area for fine grinding. |

| Material Properties (Hardness/Feed Size) | Dictates the required energy and media size for effective fracture. |

| Mill Filling Ratio | Affects media movement and energy transfer; optimal between 30-45% of mill volume. |

Ready to maximize your ball mill's efficiency and reduce energy costs? KINTEK specializes in high-performance lab equipment and consumables, including grinding media and milling solutions tailored to your specific material and particle size goals. Our experts can help you optimize your process for superior results. Contact our team today to discuss your laboratory needs!

Visual Guide

Related Products

- High Energy Planetary Ball Mill Machine for Laboratory Horizontal Tank Type

- Mini Planetary Ball Mill Machine for Laboratory Milling

- Liquid Nitrogen Cryogenic Grinder Mill Cryomill Airflow Ultrafine Pulverizer

- Small Injection Molding Machine for Lab Use

- Manual Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

People Also Ask

- How does a planetary ball mill enhance the electrocatalytic activity of La0.6Sr0.4CoO3-δ? Boost Your Catalyst Performance

- What is the specific role of a high-energy planetary ball mill in the synthesis of Ag-doped sulfide solid-state electrolytes?

- Why are high-intensity planetary ball mills preferred for reducing the crystallinity of lignocellulose?

- What is the function of a high-energy planetary ball mill in the synthesis of iodo-vanadate-lead ceramic waste forms?

- How does a planetary high-energy ball mill contribute to the top-down preparation of layered materials? Optimize Yield