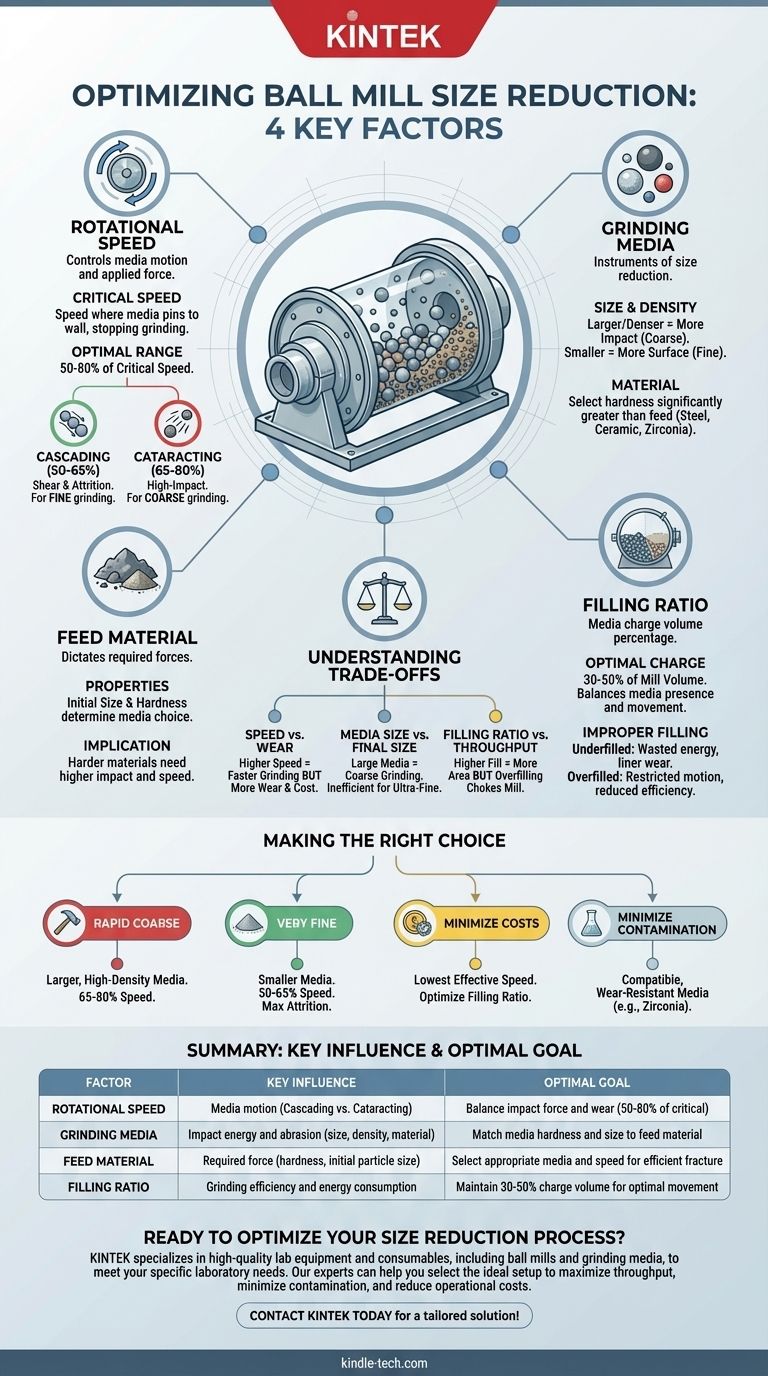

To precisely control the size reduction process in a ball mill, you must strategically manage four interconnected factors. These are the rotational speed of the mill, the size and material of the grinding media, the characteristics of the material being ground, and the volume of media loaded into the mill, known as the filling ratio.

The key to effective ball milling is not about maximizing any single variable, but about achieving a specific balance between them. This balance dictates the dominant grinding action—either high-impact crushing or fine abrasive grinding—to efficiently achieve your desired final particle size.

The Role of Rotational Speed

The speed at which the mill rotates is arguably the most critical operational parameter. It directly controls the motion of the grinding media and, therefore, the type of force applied to your material.

Defining Critical Speed

Critical speed is the theoretical rotational speed at which the outermost layer of grinding media will be pinned to the mill's inner wall by centrifugal force. Operating at or above this speed stops all grinding action.

Cascading Action (Lower Speeds)

At lower speeds (typically 50-65% of critical speed), the grinding media tumbles over itself in a "cascading" motion. This creates significant shear and attrition forces, ideal for achieving a very fine, uniform particle size through abrasion.

Cataracting Action (Higher Speeds)

At higher speeds (typically 65-80% of critical speed), the media is thrown across the mill, creating a "cataracting" motion. This generates high-energy impact forces, which are highly effective for breaking down coarser, larger particles quickly.

Characteristics of the Grinding Media

The balls or cylinders used as the grinding medium are the instruments that perform the size reduction. Their properties are just as important as the mill's speed.

Media Size and Density

The size of the media directly correlates with the impact force. Larger, denser media (like steel balls) deliver more energy per impact, making them suitable for breaking large, hard feed material. Smaller media provides more surface area and contact points, promoting the attrition needed for ultra-fine grinding.

Media Material

The material of the media—such as steel, ceramic, or zirconia—determines its hardness, density, and potential for product contamination. You must select a media material that is significantly harder than the material being ground to ensure effective grinding and minimize wear.

Properties of the Feed Material

The starting material itself dictates many of the other process parameters. Its inherent properties will determine how it responds to the forces inside the mill.

Initial Size and Hardness

The initial particle size of your feed material is a primary factor in selecting the appropriate grinding media size. Harder, more durable materials require higher impact forces (and thus higher speeds or denser media) to fracture effectively.

Understanding the Filling Ratio

The filling ratio, or charge volume, is the percentage of the mill's internal volume occupied by the grinding media. This seemingly simple factor has a profound effect on efficiency.

Optimal Charge Volume

Most ball mills operate most efficiently with a media charge between 30% and 50% of the total mill volume. This range provides a good balance, ensuring enough media is present to grind effectively without restricting its movement.

Effects of Improper Filling

An underfilled mill wastes energy, as impacts occur against the mill liner instead of the material, causing excessive wear. An overfilled mill restricts the motion of the media, dampening the cascading or cataracting action and severely reducing grinding efficiency.

Understanding the Trade-offs

Optimizing a ball mill requires balancing competing factors. Changing one variable will invariably affect the ideal setting for another.

Speed vs. Wear

Increasing rotational speed accelerates grinding but also dramatically increases the rate of wear on both the grinding media and the mill's internal liners. This directly impacts operational costs and maintenance schedules.

Media Size vs. Final Particle Size

While large media are excellent for breaking down coarse feed, they are inefficient at producing ultra-fine particles. Once the material is ground down to a certain size, the large gaps between the big balls prevent further effective attrition.

Filling Ratio vs. Throughput

A higher filling ratio can increase the grinding surface area, but only up to a point. Overfilling chokes the mill, preventing the free-fall impact necessary for coarse grinding and reducing the overall efficiency and net throughput of the system.

Making the Right Choice for Your Goal

Your ideal parameters depend entirely on your desired outcome. Use these principles as a starting point for process optimization.

- If your primary focus is rapid coarse grinding: Use larger, high-density media at a higher speed (65-80% of critical) to maximize impact forces.

- If your primary focus is producing very fine particles: Use smaller media at a lower speed (50-65% of critical) to promote a cascading action that maximizes abrasive attrition.

- If your primary focus is minimizing operational costs: Operate at the lowest effective speed to reduce media and liner wear, and carefully optimize the filling ratio to avoid wasted energy.

- If your primary focus is minimizing product contamination: Choose grinding media made from a material (e.g., zirconia, alumina) that is chemically compatible with your product and highly resistant to wear.

Mastering these interconnected variables transforms the ball mill from a simple machine into a precision instrument for material processing.

Summary Table:

| Factor | Key Influence | Optimal Goal |

|---|---|---|

| Rotational Speed | Controls media motion (cascading vs. cataracting) | Balance impact force and wear (50-80% of critical speed) |

| Grinding Media | Determines impact energy and abrasion (size, density, material) | Match media hardness and size to feed material |

| Feed Material | Dictates required force (hardness, initial particle size) | Select appropriate media and speed for efficient fracture |

| Filling Ratio | Affects grinding efficiency and energy consumption | Maintain 30-50% charge volume for optimal media movement |

Ready to Optimize Your Size Reduction Process?

Choosing the right ball mill parameters is critical for achieving your target particle size efficiently. KINTEK specializes in high-quality lab equipment and consumables, including ball mills and grinding media, to meet your specific laboratory needs. Our experts can help you select the ideal setup to maximize throughput, minimize contamination, and reduce operational costs.

Contact KINTEL today to discuss your application and get a tailored solution for your grinding challenges!

Visual Guide

Related Products

- Stainless Steel Laboratory Ball Mill for Dry Powder and Liquid with Ceramic Polyurethane Lining

- Laboratory Ball Mill Jar Mill with Metal Alloy Grinding Jar and Balls

- Laboratory Single Horizontal Jar Mill

- Laboratory Planetary Ball Mill Rotating Ball Milling Machine

- Laboratory Four-Body Horizontal Jar Mill

People Also Ask

- Why is high-performance mixing equipment necessary for the wide-gap brazing process? Ensure Structural Integrity

- What core function does a high-power ball mill perform for nano-lead powder? Optimize Your Gamma-Ray Shielding

- Through what mechanism does a mechanical ball mill function in top-down nanostructuring? Achieve Precision Nano-Sizing

- What is the role of a high-energy horizontal ball mill in the mechanical alloying of 14Cr ODS ferritic steel?

- Why is ball milling equipment required in Cold Sintering? Master Particle Refinement for Optimal Density

- What is the role of high-energy ball milling in the synthesis of sulfide solid-state electrolytes? Powering Synthesis

- What is the process of planetary mill? Unlock High-Energy Grinding for Fine Powders

- What is the function of a high-energy ball mill in the 'top-down' synthesis of nanomaterials? Boost Chemical Reactivity