At their core, ultra-low temperature (ULT) freezers are defined by three key construction principles: a powerful multi-stage cooling system, exceptionally robust insulation, and a sophisticated network of monitoring and alarm systems. These elements work in concert to achieve and, more importantly, reliably maintain extreme temperatures between -40°C and -86°C for the long-term preservation of invaluable biological samples.

The construction of a ULT freezer is less about simply achieving cold and more about creating an unwavering fortress of stability. Every feature, from the refrigeration system to the door handle, is engineered with redundancy and security in mind to protect irreplaceable assets from temperature fluctuations.

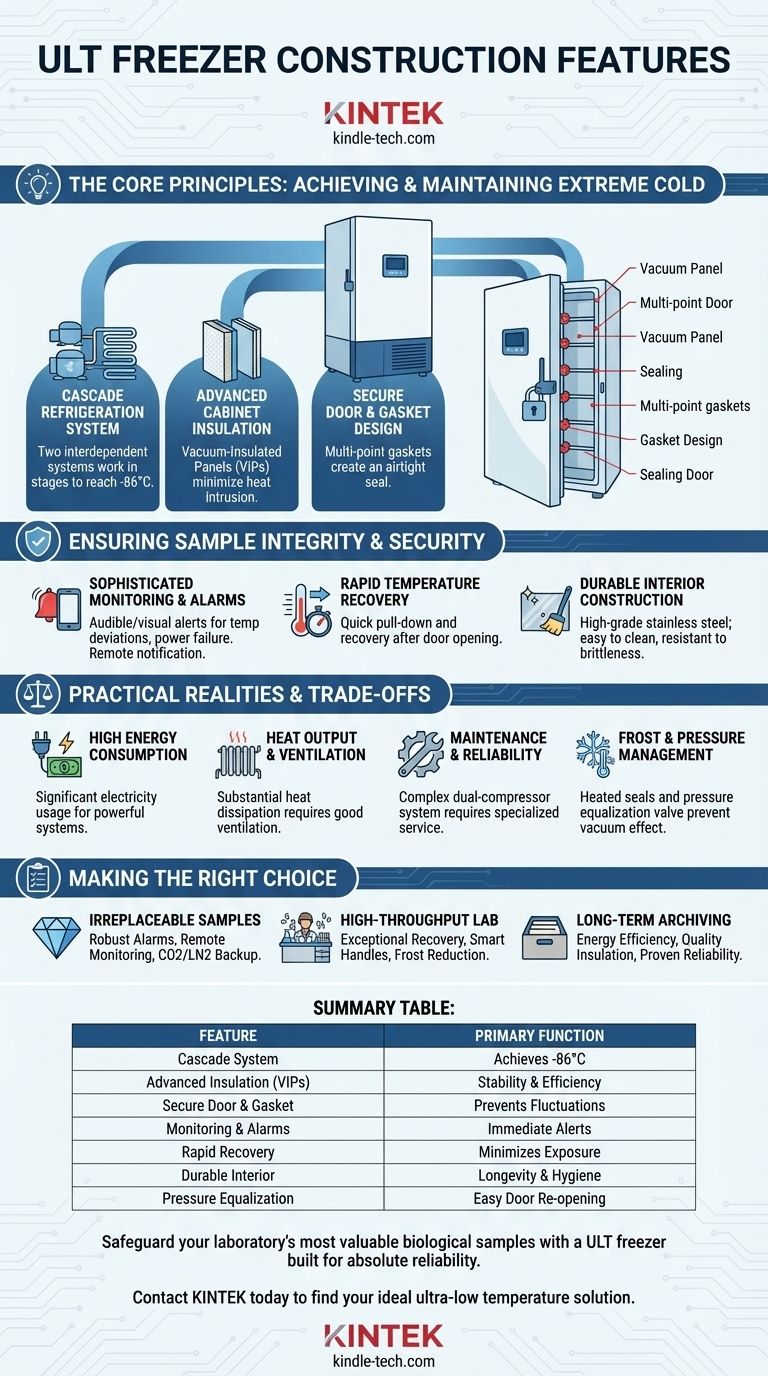

The Core Principle: Achieving and Maintaining Extreme Cold

A ULT freezer’s primary function is to create a stable, deep-frozen environment. This requires a specialized approach far beyond that of a conventional freezer, focusing on both the cooling engine and the physical cabinet that contains the cold.

The Cascade Refrigeration System

The heart of a ULT freezer is its cascade refrigeration system. This isn't a single cooling unit but two interdependent systems working in stages.

The first stage cools the second, allowing the second system to reach much lower temperatures than a single-compressor unit ever could. This design is fundamental to achieving the target -86°C range.

Advanced Cabinet Insulation

To maintain these temperatures efficiently, the freezer cabinet is built with exceptionally thick walls containing high-performance insulation. This often includes vacuum-insulated panels (VIPs), which offer significantly better thermal resistance than traditional foam, minimizing heat intrusion and reducing energy consumption.

Secure Door and Gasket Design

The door is a critical point of potential failure. ULT freezers feature multi-point gaskets to create a virtually airtight seal. This prevents ambient air from leaking in, which would cause temperature instability and significant frost formation.

Ensuring Sample Integrity and Security

Once the temperature is achieved, the freezer's design shifts focus to guaranteeing the safety and integrity of the materials stored inside. This is where monitoring, alarms, and physical construction become paramount.

Sophisticated Monitoring and Alarms

ULT freezers are equipped with comprehensive audible and visual alarm systems. These immediately alert users to any temperature deviations, power failures, or door-ajar events. Many systems also include remote alerting capabilities, notifying personnel via text or email if a critical failure occurs.

Rapid Temperature Recovery

Every time the door is opened, warm air enters and the internal temperature rises. Key performance features include quick temperature pull-down (the initial cooling time) and rapid recovery after a door opening. This minimizes the duration of temperature exposure for sensitive samples.

Durable Interior Construction

The interior chamber is typically constructed from high-grade stainless steel. This material is not only easy to clean and decontaminate but is also incredibly durable, resisting the brittleness that can affect other materials at such extreme temperatures.

Understanding the Trade-offs and Practical Realities

The specialized construction of a ULT freezer brings with it a unique set of operational considerations. Understanding these is crucial for proper lab planning and management.

High Energy Consumption

The powerful cascade compressor systems required to maintain -86°C consume a significant amount of electricity. While modern models are increasingly energy-efficient, they remain one of the more power-hungry pieces of equipment in a typical lab.

Heat Output and Ventilation

A direct byproduct of the refrigeration cycle is heat. ULT freezers dissipate a substantial amount of heat into the surrounding room, requiring placement in a well-ventilated area to prevent overheating of the unit and the room itself.

Maintenance and Reliability

The dual-compressor cascade system is more complex than a standard freezer's. While built for reliability, it requires specialized technicians for service and repair. Sturdy components, like durable door handles and latches, are essential to withstand rugged daily use and reduce mechanical failures.

Frost and Pressure Management

Rapid cooling of entering air can cause frost buildup and create a vacuum effect, making the door difficult to reopen immediately. To combat this, many models include heated seals to reduce frost and a heated pressure equalization valve to allow for easy re-entry shortly after closing the door.

Making the Right Choice for Your Goal

Selecting a ULT freezer means matching its specific construction features to the primary needs of your laboratory and the value of the samples you intend to store.

- If your primary focus is irreplaceable samples: Prioritize models with the most robust alarm systems, remote monitoring, and options for CO2 or LN2 backup systems.

- If your primary focus is a high-throughput lab with frequent access: Look for exceptional temperature recovery times, ergonomic smart handles, and effective frost-reduction features.

- If your primary focus is long-term archiving with limited access: Emphasize energy efficiency, high-quality vacuum insulation, and proven long-term reliability to minimize operating costs.

Understanding these foundational features empowers you to select a system that acts as a true safeguard for your critical work.

Summary Table:

| Key Construction Feature | Primary Function |

|---|---|

| Cascade Refrigeration System | Achieves extreme temperatures down to -86°C. |

| Advanced Cabinet Insulation (e.g., VIPs) | Maintains temperature stability and improves energy efficiency. |

| Secure Door & Gasket Design | Creates an airtight seal to prevent temperature fluctuations. |

| Sophisticated Monitoring & Alarms | Provides immediate alerts for temperature deviations or failures. |

| Rapid Temperature Recovery | Minimizes sample exposure to warm air after door openings. |

| Durable Interior (Stainless Steel) | Ensures longevity and easy decontamination. |

| Heated Pressure Equalization Valve | Prevents vacuum seal and allows for easy door re-opening. |

Safeguard your laboratory's most valuable biological samples with a ULT freezer built for absolute reliability. KINTEK specializes in providing high-performance lab equipment, including ultra-low temperature freezers designed with the robust construction features detailed above. Our freezers ensure the stable, long-term preservation your critical research demands. Let our experts help you select the perfect model for your lab's specific needs—whether it's for high-throughput access, long-term archiving, or maximum sample security. Contact KINTEK today to find your ideal ultra-low temperature solution.

Visual Guide

Related Products

- 158L Precision Vertical Ultra Low Freezer for Laboratory Applications

- 938L Vertical Ultra Low Temperature Freezer for Advanced Laboratory Storage

- 108L Vertical Ultra Low Temperature ULT Freezer

- 408L Advanced Vertical Laboratory Ultra Low Temperature Freezer for Critical Research Material Preservation

- 808L Precision Laboratory Vertical Ultra Low Temperature Freezer

People Also Ask

- Why are ULT freezers considered vital equipment in labs? Ensuring Uncompromised Sample Integrity for Critical Research

- How do ultra-low temperature freezers work? Unlocking the Secrets of -86°C Sample Preservation

- What types of materials are commonly stored in ultra low temperature freezers? Preserving Cells, Vaccines & Biomolecules

- How is temperature controlled in ultra low temperature freezers? A Guide to Stable -80°C Storage

- How are advancements in compressor technology and refrigerant fluids improving ULT freezers? Boost Efficiency & Cut Costs