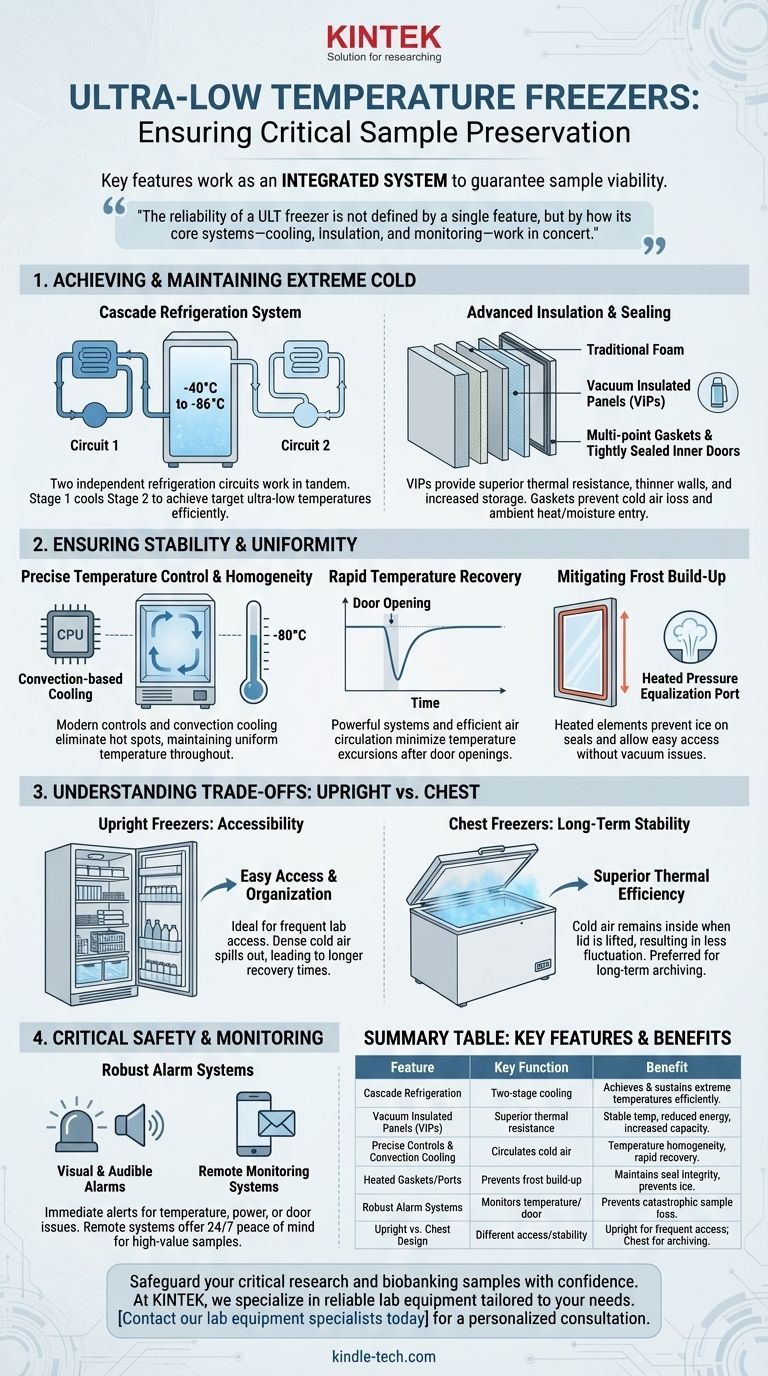

At their core, the features that ensure sample preservation in an ultra-low temperature (ULT) freezer work together as an integrated system. The primary components are an advanced cascade refrigeration system to generate extreme cold, high-efficiency insulation to maintain it, precise electronic controls for stability, and a robust alarm system to guard against failure.

The reliability of a ULT freezer is not defined by a single feature, but by how its core systems—cooling, insulation, and monitoring—work in concert. Understanding this interplay is the key to ensuring the long-term viability of your critical samples.

The Foundation: Achieving and Maintaining Extreme Cold

The first challenge for any ULT freezer is creating an environment drastically colder than its surroundings and keeping it that way with minimal energy. This is achieved through two fundamental components.

The Cascade Refrigeration System

This is the engine of the ULT freezer. Unlike a standard freezer that uses one cooling circuit, a cascade system uses two independent refrigeration circuits that work in tandem.

The first circuit cools the second, allowing the second circuit to achieve the target temperature, typically between -40°C and -86°C. This two-stage approach is essential for reaching and sustaining such extreme lows efficiently.

Advanced Insulation and Sealing

Creating cold is only half the battle; keeping it is paramount. Modern ULT freezers use vacuum insulated panels (VIPs) in addition to traditional foam insulation.

These panels provide significantly higher thermal resistance, allowing for thinner walls and more storage capacity. This is combined with multi-point gaskets and tightly sealed inner doors to prevent cold air from escaping and ambient heat and moisture from entering.

Ensuring Stability and Uniformity

For biological samples, stability is just as important as temperature. Fluctuations can cause repeated micro-thawing and refreezing, which degrades sensitive materials like RNA, DNA, and proteins over time.

Precise Temperature Control and Homogeneity

A quality ULT freezer must maintain its set temperature with minimal deviation, a concept known as temperature homogeneity. This means the temperature at the top of the freezer should be virtually identical to the temperature at the bottom.

Modern units achieve this through microprocessor controls and convection-based cooling, which circulates cold air to eliminate the "hot spots" common in older, static-wall designs.

Rapid Temperature Recovery

Every time the door is opened, warm, moist air rushes in, and the internal temperature rises. Rapid temperature recovery is a measure of how quickly the freezer can return to its setpoint after a door opening.

A powerful cascade system and efficient air circulation are critical for minimizing the duration of this temperature excursion, thereby protecting samples from thermal stress.

Mitigating Frost Build-Up

Frost is a persistent enemy of ULT freezers. It acts as an insulator, forcing the compressor to work harder, and can compromise the door seal, leading to a catastrophic loss of temperature.

Features like heated door gaskets and heated pressure equalization ports prevent ice from forming around the main door and allow easy access without creating a vacuum.

Understanding the Trade-offs: Upright vs. Chest Freezers

The physical design of the freezer has a significant impact on its performance and suitability for a given application. The choice between an upright and a chest freezer is a primary example of this.

Upright Freezers: Accessibility

Upright models offer superior organization and easy access to samples via shelves and racks. This makes them ideal for labs where materials are accessed frequently.

However, when the door is opened, the dense, cold air spills out, leading to greater temperature loss and longer recovery times compared to chest freezers.

Chest Freezers: Long-Term Stability

Chest freezers are inherently more thermally efficient. Because cold air is denser than warm air, it remains inside the chamber when the lid is lifted.

This results in less temperature fluctuation during access and greater stability, making them the preferred choice for long-term archiving and biobanking where samples are not needed on a daily basis.

Critical Safety and Monitoring

Even the best freezer can fail. Monitoring and alarm systems are your final, non-negotiable line of defense against sample loss.

Visual and audible alarms provide immediate, on-site alerts for temperature deviations, power failures, or a door left ajar. For irreplaceable samples, remote monitoring systems that send text or email alerts are an essential investment, providing 24/7 peace of mind.

Making the Right Choice for Your Goal

Selecting a freezer requires matching its features to your specific workflow and the value of your samples.

- If your primary focus is active, daily research: Prioritize an upright model with rapid temperature recovery, a user-friendly interface, and excellent internal organization options.

- If your primary focus is long-term archiving or biobanking: A chest freezer offers superior thermal stability and efficiency for samples that are accessed infrequently.

- If your samples are irreplaceable or high-value: Do not compromise on monitoring; invest in a unit with robust onboard alarms and an independent remote data logging and alert system.

- If you are replacing an older unit: Ensure any new model uses a modern cascade, convection-based cooling system, not an outdated static "cold-wall" design.

By understanding how these systems function together, you can confidently select the technology that will safeguard your valuable work for years to come.

Summary Table:

| Feature | Key Function | Benefit for Sample Preservation |

|---|---|---|

| Cascade Refrigeration | Two-stage cooling system | Achieves and sustains extreme temperatures (-40°C to -86°C) efficiently |

| Vacuum Insulated Panels (VIPs) | Superior thermal resistance | Maintains stable temperature, reduces energy use, and increases capacity |

| Precise Controls & Convection Cooling | Circulates cold air | Ensures temperature homogeneity (no hot spots) and rapid recovery after door openings |

| Heated Gaskets/Ports | Prevents frost build-up | Maintains seal integrity and prevents insulating ice from forming |

| Robust Alarm Systems | Monitors temperature and door status | Provides immediate local and remote alerts to prevent catastrophic sample loss |

| Upright vs. Chest Design | Different access and stability profiles | Upright for frequent access; Chest for superior long-term archiving stability |

Safeguard your critical research and biobanking samples with confidence. The right ultra-low temperature freezer is an investment in the integrity of your work. At KINTEK, we specialize in providing reliable lab equipment, including ULT freezers, tailored to the precise needs of research and clinical laboratories. Our experts can help you select the ideal model—whether an upright for active daily use or a chest freezer for long-term archiving—ensuring your valuable DNA, RNA, proteins, and other samples are preserved under optimal conditions. Contact our lab equipment specialists today for a personalized consultation and ensure your peace of mind.

Visual Guide

Related Products

- 58L Precision Laboratory Ultra Low Temperature Upright Freezer for Critical Sample Storage

- 158L Precision Vertical Ultra Low Freezer for Laboratory Applications

- 938L Vertical Ultra Low Temperature Freezer for Advanced Laboratory Storage

- 108L Vertical Ultra Low Temperature ULT Freezer

- 408L Advanced Vertical Laboratory Ultra Low Temperature Freezer for Critical Research Material Preservation

People Also Ask

- What are ultra-low temperature freezers designed for? Preserving Your Most Valuable Biological Samples

- How does fast temperature recovery benefit ultra-low freezers? Protect Sample Integrity and Lab Efficiency

- What are the key features to look for in an ultra-low temperature freezer for mRNA vaccine storage? Essential Features for Absolute Vaccine Integrity

- What are the recommendations for storing mRNA vaccines in ultra-low temperature freezers? Ensure Absolute Stability at -80°C

- How do ultra-low temperature freezers work? Unlocking the Secrets of -86°C Sample Preservation