While highly effective for certain applications, the primary limitations of a ball mill are its high energy consumption, slow processing speed, and significant operational noise. The mechanical action that makes it effective also introduces challenges, including contamination from wear and potential thermal damage to the material being processed.

A ball mill is a powerful tool for grinding hard, abrasive materials into a very fine powder. However, this power comes at a cost: it is an inefficient process prone to high energy use, component wear, and material contamination, making it unsuitable for applications where speed, purity, or material sensitivity are the top priorities.

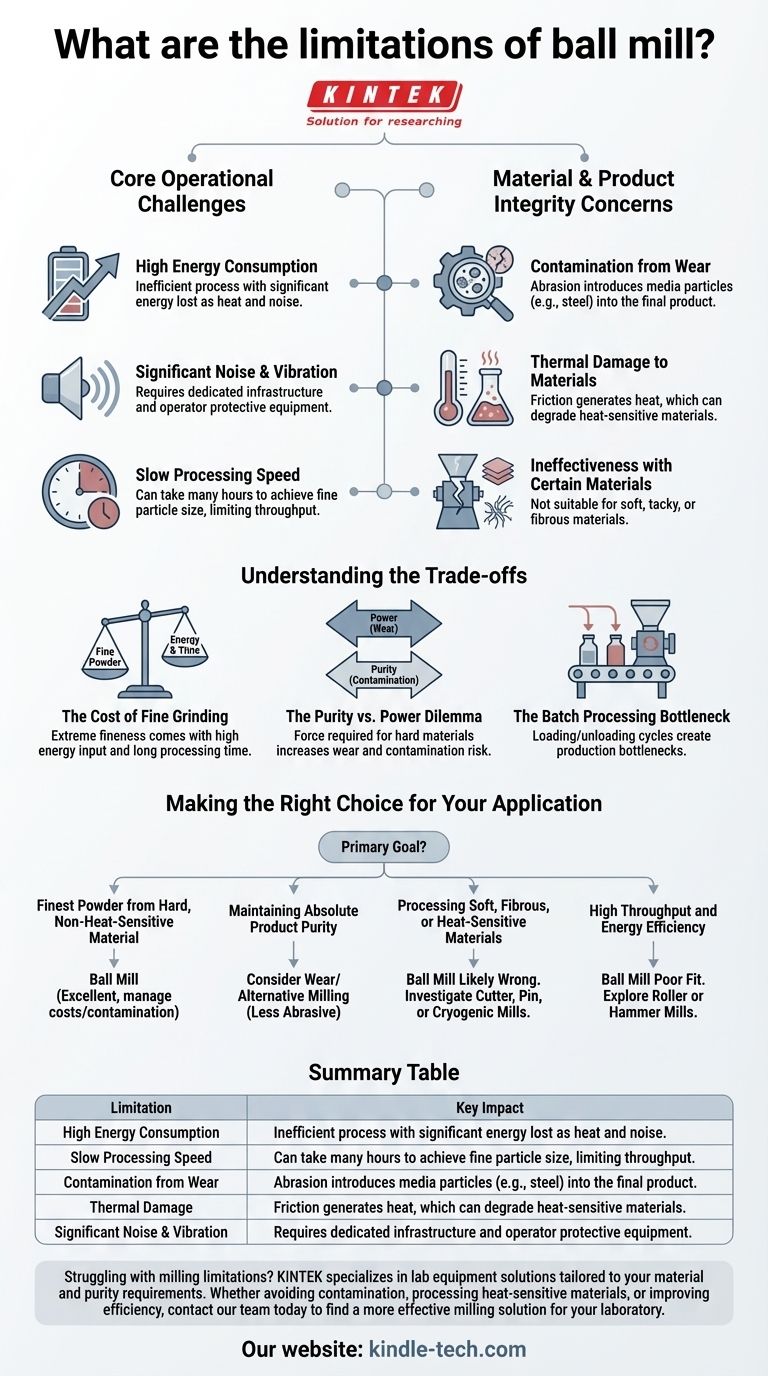

Core Operational Challenges

A ball mill's design, which relies on heavy media tumbling inside a rotating drum, leads to several inherent operational inefficiencies that must be considered.

High Energy Consumption

The process of lifting and cascading heavy grinding media (steel or ceramic balls) requires a substantial amount of energy. Much of this energy is lost as heat and noise rather than being converted directly into particle size reduction, making it an energy-intensive method.

Significant Noise and Vibration

The constant impact of the grinding media against the material and the mill's inner shell generates considerable noise and vibration. This often necessitates dedicated infrastructure, sound dampening, and personal protective equipment for operators.

Slow Processing Speed

Ball milling is fundamentally a slow, attrition-based process. Achieving the desired fine particle size can take many hours, which limits throughput and makes it less suitable for high-volume, rapid production environments compared to other milling technologies.

Material and Product Integrity Concerns

Beyond operational costs, the milling action itself can negatively impact the final product, creating limitations based on the material's properties and the required purity of the output.

Contamination from Wear

The grinding process is highly abrasive, causing both the grinding media and the inner lining of the mill to wear down over time. This wear introduces fine particles of the media (e.g., steel, ceramic) into the product, which is a critical point of failure for high-purity applications like pharmaceuticals or electronics.

Thermal Damage to Materials

Friction between the grinding media and the product generates significant heat inside the mill. This can degrade, melt, or alter the chemical properties of heat-sensitive materials, making it a poor choice for certain polymers, organic compounds, or pharmaceuticals.

Ineffectiveness with Certain Materials

Ball mills excel at grinding hard, brittle substances. However, they are largely ineffective for processing materials that are soft, tacky, or fibrous. These materials tend to coat the grinding media or agglomerate rather than breaking down into smaller particles.

Understanding the Trade-offs

Choosing a ball mill requires weighing its unique ability to produce fine powders against its significant operational and material-handling drawbacks.

The Cost of Fine Grinding

A ball mill's key advantage is its ability to produce extremely fine powders (often below 10 microns). The trade-off is the high energy input and long processing time required to achieve this, making the cost-per-kilogram of milled product relatively high.

The Purity vs. Power Dilemma

The force required to mill very hard and abrasive materials is immense. This power directly leads to the wear and contamination mentioned earlier. You must decide if the risk of contamination is acceptable for your final product.

The Batch Processing Bottleneck

While a ball mill’s enclosed nature is excellent for safely handling toxic materials, it primarily operates as a batch process. Loading, running for several hours, and then unloading creates a production bottleneck that continuous milling systems do not have.

Making the Right Choice for Your Application

To determine if a ball mill's limitations are prohibitive, evaluate your primary goal.

- If your primary focus is achieving the finest possible powder from a hard, non-heat-sensitive material: A ball mill is an excellent candidate, provided you can manage the energy costs and potential for minor contamination.

- If your primary focus is maintaining absolute product purity: You must carefully consider the wear of the grinding media or look for alternative milling methods that are less abrasive.

- If your primary focus is processing soft, fibrous, or heat-sensitive materials: A ball mill is likely the wrong choice, and you should investigate cutter, pin, or cryogenic mills instead.

- If your primary focus is high throughput and energy efficiency: The slow speed and high power consumption of a ball mill make it a poor fit; explore technologies like roller or hammer mills.

Ultimately, understanding these limitations allows you to correctly align the technology with your specific material and production goals.

Summary Table:

| Limitation | Key Impact |

|---|---|

| High Energy Consumption | Inefficient process with significant energy lost as heat and noise. |

| Slow Processing Speed | Can take many hours to achieve fine particle size, limiting throughput. |

| Contamination from Wear | Abrasion introduces media particles (e.g., steel) into the final product. |

| Thermal Damage | Friction generates heat, which can degrade heat-sensitive materials. |

| Significant Noise & Vibration | Requires dedicated infrastructure and operator protective equipment. |

Struggling with the limitations of your current milling process? KINTEK specializes in lab equipment and consumables, offering solutions tailored to your material and purity requirements. Whether you need to avoid contamination, process heat-sensitive materials, or improve efficiency, our experts can help you select the right technology. Contact our team today to discuss your specific application and find a more effective milling solution for your laboratory.

Visual Guide

Related Products

- Stainless Steel Laboratory Ball Mill for Dry Powder and Liquid with Ceramic Polyurethane Lining

- Laboratory Planetary Ball Mill Rotating Ball Milling Machine

- High Energy Planetary Ball Mill for Laboratory Horizontal Tank Type Milling Machine

- Laboratory Horizontal Planetary Ball Mill Milling Machine

- High-Energy Omnidirectional Planetary Ball Mill Milling Machine for Laboratory

People Also Ask

- How does the argon atmosphere protection in a ball mill affect the final quality of CuCr50 alloy powder? Explained

- What are the operating procedures for a ball mill? Master Speed, Media, and Material for Perfect Grinding

- What role do high-energy milling machines play in SiC mechanical alloying? Drive Nano-Scale Synthesis Efficiently

- What is the function of a ball mill during LLZTO precursor mixing? Master Microscopic Homogeneity for Electrolytes

- What is the primary purpose of using a forced-air drying oven and grinding/sieving equipment? Optimize Manure Processing

- What is the function of an ultrasonic homogenizer in Al2O3 nanoparticle preparation? Achieve Stable Dispersions

- Why are alumina grinding balls preferred for Magnesium Aluminate Spinel? Achieve Pure, High-Performance Ceramic Milling

- What are the advantages of large-diameter stainless steel grinding balls? Optimize Hydrogen Material Preparation