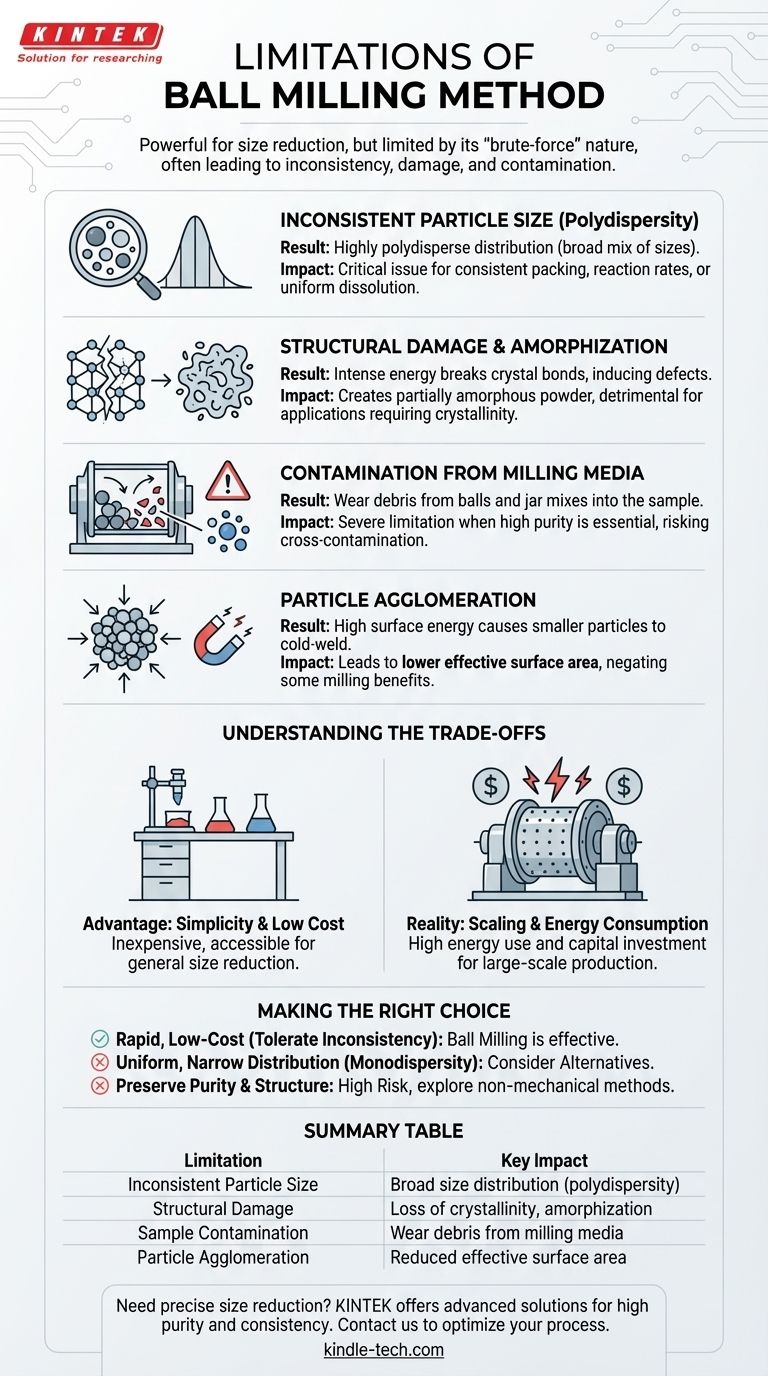

At its core, the ball milling method is a powerful tool for particle size reduction, but its primary limitations stem from its own brute-force mechanical nature. This process often results in inconsistent particle sizes, can damage the material's internal structure leading to an amorphous state, and introduces a significant risk of sample contamination from the milling media itself.

While valued for its simplicity and low cost, ball milling sacrifices precision for power. The key limitation to understand is that the same mechanical energy that breaks particles down can also cause undesirable structural changes and a lack of uniformity in the final product.

The Challenge: Uncontrolled Mechanical Energy

Ball milling operates by transferring kinetic energy from moving balls to a target material, causing fractures. All of its strengths and weaknesses derive from this simple, powerful, yet often imprecise mechanical action.

Inconsistent Particle Size (Polydispersity)

The grinding process in a ball mill is chaotic. Particles are subjected to a wide range of impact energies, leading to a highly polydisperse size distribution—meaning the final powder contains a broad mix of large and small particles.

This lack of uniformity can be a critical issue in applications requiring consistent packing density, predictable reaction rates, or uniform dissolution.

Structural Damage and Amorphization

The intense mechanical energy doesn't just break particles apart; it can also break the bonds within the material's crystal lattice. This can induce crystal defects or even destroy the crystalline structure entirely.

The result is a partially amorphous powder. For applications where crystallinity is essential (e.g., in pharmaceuticals, semiconductors, or specific catalysts), this structural damage is a major drawback.

Contamination from Milling Media

The constant, high-energy impact between the balls, the container wall, and the material causes wear. Tiny fragments of the milling balls and jar can break off and become mixed into your sample.

This cross-contamination is a severe limitation, especially when high purity is required. The choice of milling media (e.g., steel, zirconia, agate) becomes a critical factor in mitigating this, but the risk is never zero.

Particle Agglomeration

Paradoxically, the same forces that break particles down can also press them back together. As particles become smaller and their surface energy increases, they have a tendency to cold-weld or agglomerate.

This can lead to a final product with a lower effective surface area than expected, negating some of the primary benefits of milling.

Understanding the Trade-offs

Choosing a milling method is an exercise in balancing cost, speed, and final material quality. Ball milling's limitations must be weighed against its significant advantages.

The Advantage: Simplicity and Low Entry Cost

For lab-scale or less sensitive applications, ball milling is often inexpensive and easy to perform. The equipment is relatively simple, making it a highly accessible method for general-purpose size reduction.

The Reality: Scaling and Energy Consumption

While a basic setup is cheap, high-energy or large-scale industrial ball mills represent a significant capital investment. They are also energy-intensive, which can drive up operational costs for large-volume production.

Making the Right Choice for Your Application

You must evaluate the limitations of ball milling in the context of your specific goal. The "best" method is entirely dependent on what material properties you need to achieve.

- If your primary focus is rapid, low-cost size reduction and you can tolerate size inconsistency: Ball milling is an excellent and highly effective choice.

- If your primary focus is a uniform, narrow particle size distribution (monodispersity): The inherent polydispersity of ball milling is a significant hurdle, and you should consider alternative methods like jet milling or controlled precipitation.

- If your primary focus is preserving material purity and crystalline structure: The risks of contamination and amorphization are high, and you must carefully select milling media or explore non-mechanical size reduction techniques.

Ultimately, understanding the inherent limitations of ball milling is the first step toward using it effectively or choosing a more suitable alternative for your project.

Summary Table:

| Limitation | Key Impact |

|---|---|

| Inconsistent Particle Size | Broad size distribution (polydispersity) |

| Structural Damage | Loss of crystallinity, amorphization |

| Sample Contamination | Wear debris from milling media |

| Particle Agglomeration | Reduced effective surface area |

Need precise particle size reduction without the drawbacks?

Ball milling is a powerful but imprecise tool. For applications requiring high purity, consistent particle size, and preserved crystallinity, KINTEK's advanced laboratory equipment and consumables offer superior alternatives.

We provide solutions that help you avoid contamination, achieve monodisperse distributions, and protect your material's integrity. Let our experts help you select the right technology for your specific material and application goals.

Contact KINTEK today to discuss your project and optimize your process.

Visual Guide

Related Products

- Laboratory Horizontal Planetary Ball Mill Milling Machine

- Laboratory Planetary Ball Mill Rotating Ball Milling Machine

- Laboratory Planetary Ball Mill Cabinet Planetary Ball Milling Machine

- High Energy Planetary Ball Mill for Laboratory Horizontal Tank Type Milling Machine

- High-Energy Omnidirectional Planetary Ball Mill Milling Machine for Laboratory

People Also Ask

- What is the difference between a ball mill and a planetary mill? Choose the Right Grinding Tool for Your Lab

- What are the effects of ball milling? A Deep Dive into Mechanical Alloying and Material Transformation

- What is the principle of planetary ball mill? Achieve Rapid, High-Energy Grinding for Your Materials

- What is the working principle of planetary ball mill? Unlock High-Energy Grinding for Nanoscale Results

- What is the difference between a ball mill and a planetary ball mill? Unlock the Right Grinding Technology for Your Lab