While foundational to ultra-low temperature storage, conventional cold-wall freezers have significant limitations. Their primary drawbacks are inconsistent temperature uniformity, slow temperature recovery after door openings, and reduced efficiency in high-demand environments. These issues stem directly from their passive cooling design, which relies on refrigerant lines embedded within the freezer walls.

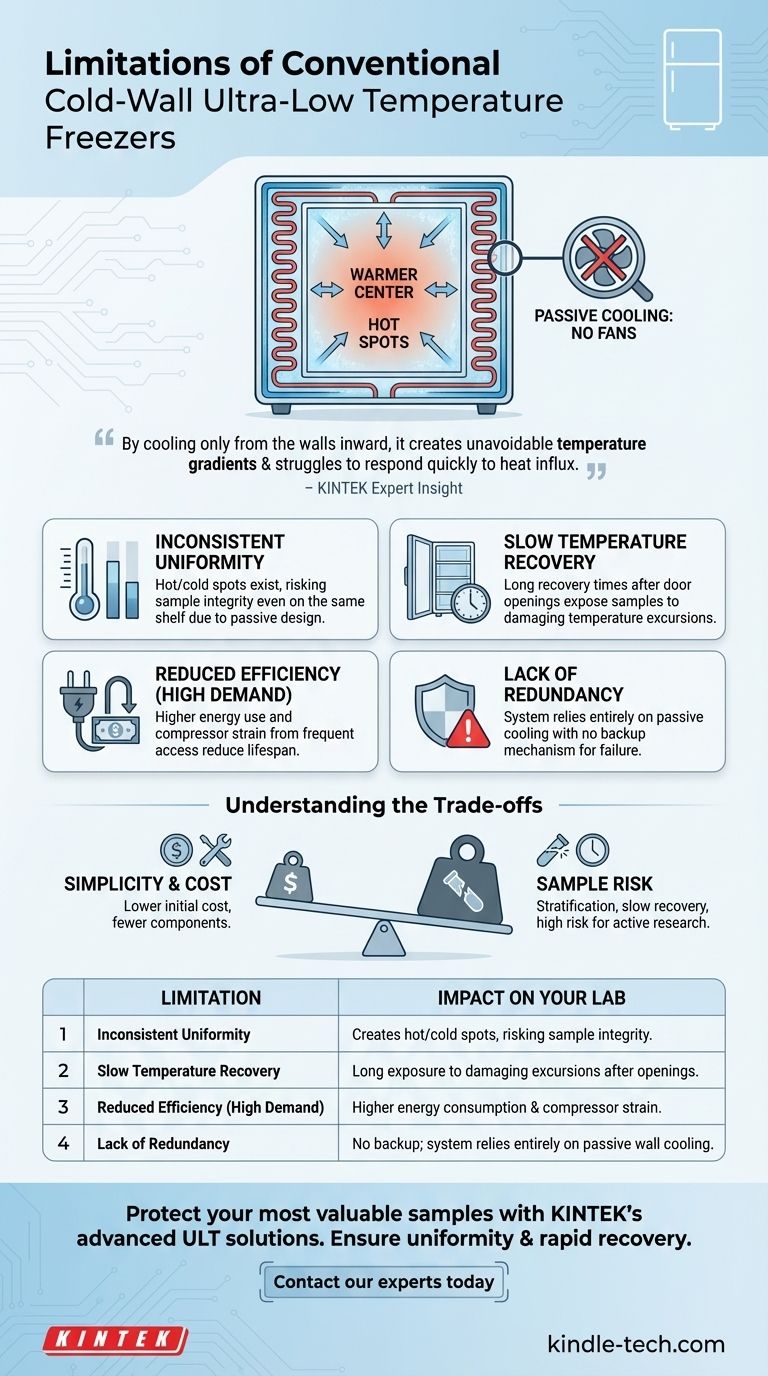

The core limitation of a cold-wall freezer is its passive cooling mechanism. By cooling only from the walls inward, it creates unavoidable temperature gradients and struggles to respond quickly to heat influx, placing frequently accessed or highly sensitive samples at risk.

The Cold-Wall Cooling Mechanism

At its core, an ultra-low temperature (ULT) freezer's job is to maintain a stable environment, typically between -40°C and -86°C, to preserve the long-term integrity of biological samples, reagents, and other critical materials. The method used to achieve this cooling is what defines its performance.

How Passive Cooling Works

A conventional cold-wall freezer cools its interior by circulating refrigerant through a network of tubes embedded directly within the cabinet's insulated walls. Heat from the chamber passively radiates toward these cold surfaces, where it is absorbed and carried away by the refrigeration system. There are no fans to actively circulate the cold air.

The Impact on Internal Environment

This passive design means the areas closest to the walls are the coldest, while the center of the chamber is the warmest. This creates a permanent temperature gradient within the storage space. The system relies on inner doors for each shelf to minimize the loss of cold air when the main door is opened.

Core Limitations of the Cold-Wall Design

The passive nature of cold-wall technology is both its simplest feature and the source of its most critical operational weaknesses, particularly in a busy laboratory setting.

Inconsistent Temperature Uniformity

Because cooling is not actively distributed, temperature uniformity is a major challenge. It's common to have "hot spots" in the center of shelves and "cold spots" near the walls. This lack of uniformity can lead to inconsistent storage conditions for samples, even if they are stored on the same shelf.

Slow Temperature Recovery

When the main door is opened, warm, moist ambient air rushes in. A cold-wall freezer lacks fans to quickly mix this warm air with the existing cold air and redistribute it. As a result, it can take a significantly longer time for the freezer to return to its setpoint, exposing all samples to a potentially damaging temperature excursion.

Reduced Efficiency in High-Demand Labs

In environments with frequent door openings, the compressor in a cold-wall freezer must run for extended periods to slowly pull the temperature back down. This not only consumes more energy but also puts greater strain on the refrigeration system, potentially reducing its operational lifespan.

Lack of Redundancy

The passive design lacks the redundancy of a fan-assisted system. There is no mechanism to help distribute cooling if one section of the wall's refrigerant lines becomes less efficient. The system is entirely dependent on passive radiation and conduction.

Understanding the Trade-offs

While modern convection freezers have addressed many of these issues, it's important to understand why cold-wall designs persist and what risks they entail.

Simplicity vs. Performance

The primary advantage of a cold-wall design is its mechanical simplicity. With no fans or air ducts inside the chamber, there are fewer components that can fail. This often translated to a lower initial purchase price.

The Risk of Sample Stratification

The most significant trade-off is the risk to your samples. Placing a highly sensitive sample in a "hot spot" without realizing it can compromise its integrity over time. This sample stratification based on location is a critical flaw for precise scientific work.

The Danger of Frequent Access

For active research collections that are accessed multiple times per day, the slow temperature recovery of a cold-wall unit poses a constant threat. Each door opening initiates a lengthy recovery cycle, compounding the temperature stress on your valuable assets.

Making the Right Choice for Your Application

The choice between a cold-wall and a modern convection-based freezer depends entirely on your specific application and workflow.

- If your primary focus is low-budget, long-term archival of non-critical samples: A cold-wall freezer may be a cost-effective solution, as long as access is infrequent.

- If your primary focus is active research with frequent sample access: The slow recovery times of a cold-wall design pose a significant risk, and a modern, fan-assisted convection freezer is strongly recommended.

- If your primary focus is maximum sample integrity and safety: A convection freezer provides superior temperature uniformity and rapid recovery, offering the best protection for your most valuable and irreplaceable assets.

Understanding these fundamental design differences empowers you to select the technology that best protects your critical work.

Summary Table:

| Limitation | Impact on Your Lab |

|---|---|

| Inconsistent Temperature Uniformity | Creates hot/cold spots, risking sample integrity even on the same shelf. |

| Slow Temperature Recovery | Long recovery times after door openings, exposing all samples to damaging excursions. |

| Reduced Efficiency in High-Demand Labs | Higher energy consumption and compressor strain from frequent use. |

| Lack of Redundancy | No backup cooling mechanism; system relies entirely on passive wall cooling. |

Protect your most valuable samples with the right ultra-low temperature solution.

Conventional cold-wall freezers can jeopardize sample integrity with their slow recovery and inconsistent temperatures. For active research labs that demand maximum protection, a modern convection-based ULT freezer is essential.

KINTEK specializes in lab equipment and consumables, serving laboratory needs. We provide reliable, high-performance ultra-low temperature freezers designed to ensure temperature uniformity and rapid recovery, safeguarding your critical work.

Ready to enhance your sample storage security? Contact our experts today to find the perfect ULT freezer for your application and workflow.

Visual Guide

Related Products

- 58L Precision Laboratory Ultra Low Temperature Upright Freezer for Critical Sample Storage

- 158L Precision Vertical Ultra Low Freezer for Laboratory Applications

- 938L Vertical Ultra Low Temperature Freezer for Advanced Laboratory Storage

- 108L Vertical Ultra Low Temperature ULT Freezer

- 408L Advanced Vertical Laboratory Ultra Low Temperature Freezer for Critical Research Material Preservation

People Also Ask

- What are ultra-low temperature freezers designed for? Preserving Your Most Valuable Biological Samples

- How does fast temperature recovery benefit ultra-low freezers? Protect Sample Integrity and Lab Efficiency

- What features do ultra-low temperature freezers typically include? Ensuring Absolute Sample Security

- How do ultra-low temperature freezers work? Unlocking the Secrets of -86°C Sample Preservation

- What are the recommendations for storing mRNA vaccines in ultra-low temperature freezers? Ensure Absolute Stability at -80°C