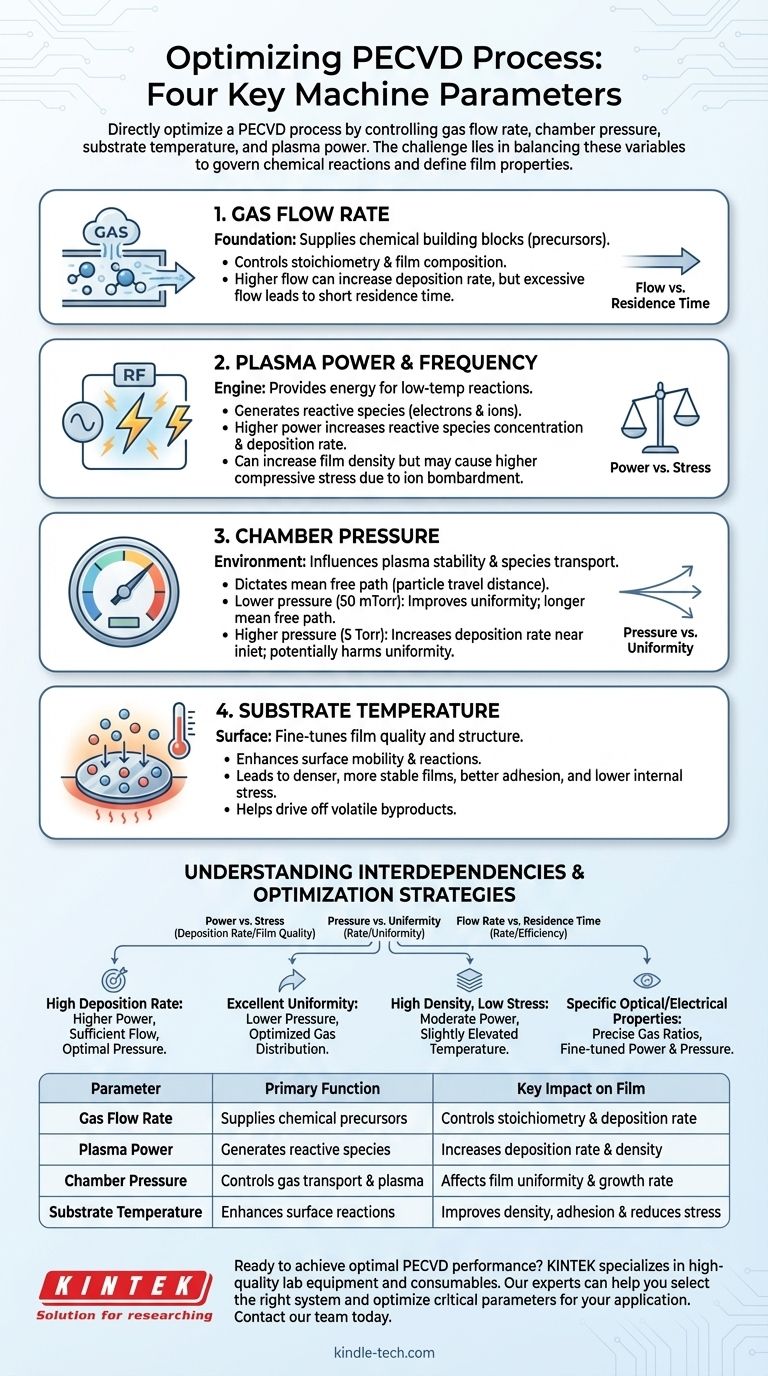

To directly optimize a PECVD process, you must control four primary machine parameters: gas flow rate, chamber pressure, substrate temperature, and the power supplied to generate the plasma. These variables work together to control the chemical reactions and the resulting properties of the deposited thin film.

The core challenge of PECVD optimization is not just adjusting individual parameters, but understanding their interplay. You are balancing the creation of reactive chemical species in the plasma with their controlled transport and reaction on the substrate surface.

The Foundation: Gas Composition and Flow Rate

Gas is the raw material for your thin film. Controlling its composition and flow is the first step in defining the film's chemistry and growth rate.

Controlling the Chemical Building Blocks

The gases you introduce into the chamber, known as precursors, contain the atoms that will form your final film. The gas flow rate, managed by mass flow controllers, determines the quantity of these building blocks available for the reaction.

Changing the ratio of different gases allows you to control the film's stoichiometry—for example, the ratio of silicon to nitrogen in a silicon nitride film.

Impact on Deposition Rate

Higher gas flow rates can increase the deposition rate, but only up to a point. If the flow is too high, the precursor gases may be pumped out of the chamber before they have time to react, a condition known as a short residence time.

The Engine: Plasma Power and Frequency

Plasma is the defining feature of PECVD, providing the energy to drive chemical reactions at low temperatures. The power and frequency settings directly control the plasma's characteristics.

Generating Reactive Species

An RF power source, typically operating between 100 kHz and 40 MHz, energizes the gas into a plasma state. This plasma power controls the density of electrons and ions.

Higher power levels break down more precursor gas molecules, creating a higher concentration of the reactive species needed for deposition. This generally leads to a faster deposition rate.

Influence on Film Density and Stress

The energy of the plasma also affects the film's structural properties. While higher power can increase density, it can also increase the kinetic energy of ions bombarding the substrate, which may lead to higher compressive stress within the film.

The Environment: Chamber Pressure

Chamber pressure is a critical parameter that influences both the plasma itself and the transport of reactive species to the substrate. It is typically maintained in a range between 50 mTorr and 5 Torr.

Balancing Plasma Stability and Transport

Pressure dictates the mean free path of molecules—the average distance a particle travels before colliding with another.

At lower pressures, the mean free path is long. This improves the uniformity of the film across the substrate, as reactive species can travel further without colliding.

At higher pressures, the mean free path is short, leading to more collisions in the gas phase. This can increase the deposition rate near the gas inlet but may harm uniformity.

The Surface: Substrate Temperature

While PECVD's main advantage is its low-temperature operation compared to thermal CVD, the substrate temperature remains a crucial parameter for fine-tuning film quality.

Enhancing Surface Reactions and Quality

Heating the substrate provides additional energy to the depositing species. This enhances their surface mobility, allowing them to find more stable, lower-energy sites on the surface.

This process generally results in denser, more stable films with better adhesion and lower internal stress. It also helps drive off volatile byproducts from the film's surface during growth.

Understanding the Interdependencies and Trade-offs

Optimizing one parameter in isolation is rarely effective. The true skill lies in managing the trade-offs that arise from their interactions.

Power vs. Stress

Increasing plasma power to boost deposition rate is a common goal. However, this often leads to more aggressive ion bombardment, which can increase the intrinsic stress of the film, potentially causing peeling or cracking.

Pressure vs. Uniformity

Lowering chamber pressure is a standard technique for improving film uniformity. The trade-off is that it can reduce the deposition rate and, below a certain point, may make the plasma more difficult to sustain stably.

Flow Rate vs. Residence Time

A high gas flow can replenish precursors quickly, but if it's too high relative to the chamber volume and pumping speed, the gas molecules won't have enough time (residence time) to be dissociated by the plasma and react on the surface.

Optimizing for Your Primary Goal

Your specific optimization strategy depends entirely on what film property you prioritize.

- If your primary focus is a high deposition rate: Start with higher plasma power and a pressure regime known to support high deposition, ensuring precursor gas flow is sufficient but not excessive.

- If your primary focus is excellent film uniformity: Prioritize lower chamber pressure to increase the mean free path and consider optimizing the gas distribution through the showerhead design.

- If your primary focus is high film density and low stress: Use moderate plasma power and leverage a slightly elevated substrate temperature to give depositing atoms the energy to settle into ideal locations.

- If your primary focus is specific optical or electrical properties: Precise control over gas ratios is paramount, followed by fine-tuning of power and pressure to control film density and structure, which directly impact these properties.

Mastering PECVD is about learning to manipulate this dynamic interplay of gas, plasma, and heat to consistently achieve your desired film characteristics.

Summary Table:

| Parameter | Primary Function | Key Impact on Film |

|---|---|---|

| Gas Flow Rate | Supplies chemical precursors | Controls stoichiometry & deposition rate |

| Plasma Power | Generates reactive species | Increases deposition rate & density |

| Chamber Pressure | Controls gas transport & plasma | Affects film uniformity & growth rate |

| Substrate Temperature | Enhances surface reactions | Improves density, adhesion & reduces stress |

Ready to achieve optimal PECVD performance in your lab?

KINTEK specializes in high-quality lab equipment and consumables for all your deposition needs. Our experts can help you select the right PECVD system and optimize these critical parameters for your specific application—whether you prioritize high deposition rates, excellent uniformity, or specific film properties.

Contact our team today to discuss how we can enhance your thin-film research and production.

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

People Also Ask

- What is the difference between PECVD and APCVD? Choose the Right CVD Method for Your Application

- Can plasma enhanced CVD deposit metals? Why PECVD is rarely used for metal deposition

- What is the process of PECVD in semiconductor? Enabling Low-Temperature Thin Film Deposition

- Why is a Matching Network Indispensable in RF-PECVD for Siloxane Films? Ensure Stable Plasma and Uniform Deposition

- How do PECVD systems improve DLC coatings on implants? Superior Durability and Biocompatibility Explained