In short, vapor phase deposition is the dominant method for preparing optical fiber glass because it achieves a level of material purity and structural precision that is impossible with older techniques. This process allows for the fabrication of glass with nearly non-existent optical absorption and a perfectly tailored internal structure, which are the two fundamental requirements for modern high-performance optical communication.

The core problem in making optical fiber is not simply creating glass, but creating a flawless transmission medium. Vapor phase deposition's primary advantage is its "bottom-up" approach, building the glass molecule by molecule from ultra-pure gaseous chemicals, thereby eliminating the impurities and inconsistencies inherent in traditional glass melting methods.

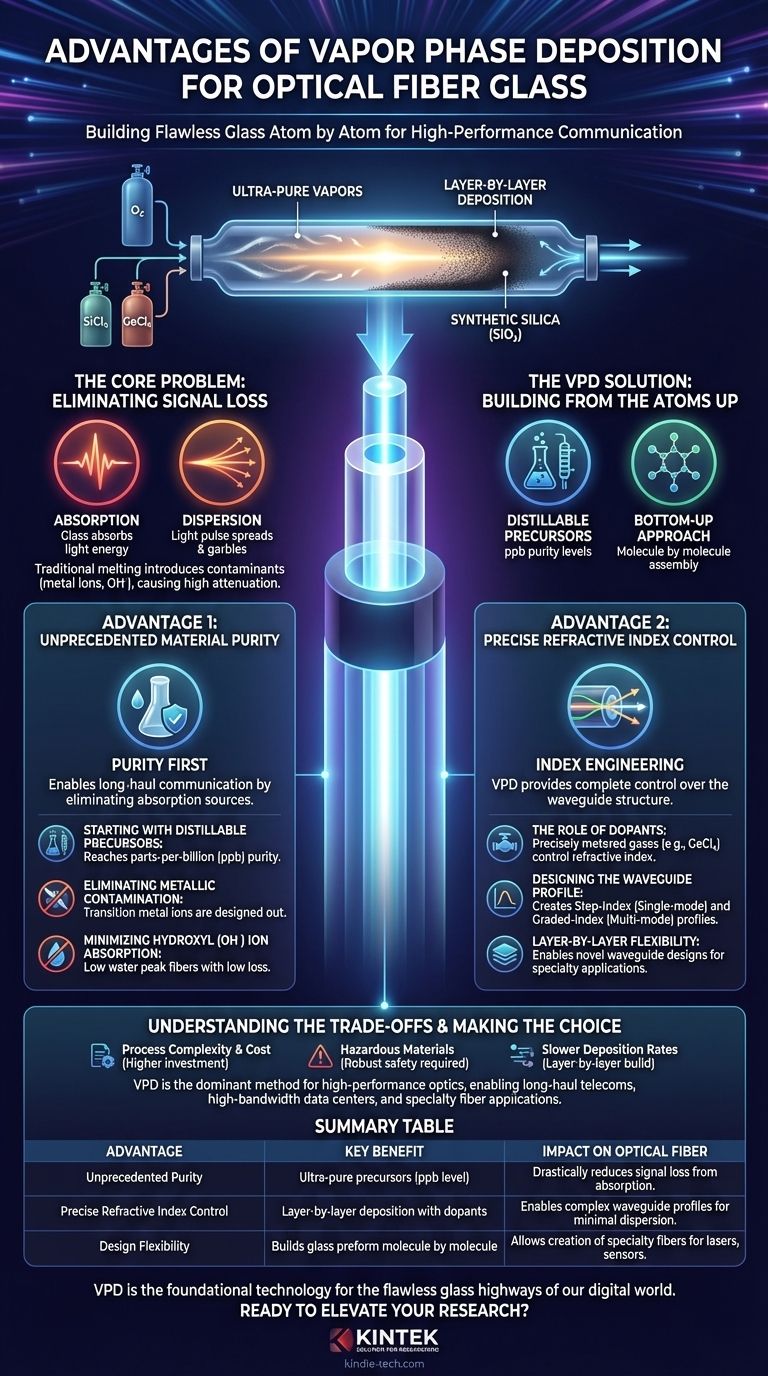

The Core Problem: Eliminating Signal Loss

The goal of an optical fiber is to guide a light signal over vast distances with minimal degradation. The two primary enemies of this goal are absorption, where the glass material itself absorbs light energy, and dispersion, where the light pulse spreads out and becomes garbled.

The Limitation of Traditional Melting

Early methods involved melting solid rods of high-purity glass together in a crucible. While functional, this "top-down" approach has severe limitations.

Contaminants from the raw silica powders and the crucible walls, particularly transition metal ions (like iron and copper) and hydroxyl (OH⁻) water ions, would inevitably get mixed into the glass. These impurities are disastrous, as they strongly absorb light at the wavelengths used for communication, leading to high signal loss (attenuation).

The Vapor Phase Solution: Building from the Atoms Up

Vapor phase deposition (VPD) techniques, such as Modified Chemical Vapor Deposition (MCVD), fundamentally changed the process. Instead of melting a solid, VPD starts with highly volatile liquid chemicals like silicon tetrachloride (SiCl₄) and germanium tetrachloride (GeCl₄).

These liquids are heated into a vapor, mixed with oxygen, and passed through a silica tube. A controlled heat source then causes a chemical reaction, depositing ultra-pure, synthetic silica (SiO₂) in fine, soot-like layers on the inside of the tube. This "preform" is then collapsed and drawn into a fiber.

Advantage 1: Unprecedented Material Purity

This is the single most important advantage. The ability to create glass free from optical absorption sources is what enables long-haul communication.

Starting with Distillable Precursors

The liquid precursors (SiCl₄, GeCl₄) can be purified through fractional distillation to an astonishing degree, reaching parts-per-billion (ppb) purity levels. This is orders of magnitude purer than any solid raw material used in melting.

Eliminating Metallic Contamination

Transition metal ions are a primary cause of absorption. By starting with ultra-pure vapors and depositing them in a closed, controlled system, these metallic contaminants are effectively designed out of the process from the very beginning.

Minimizing Hydroxyl (OH⁻) Ion Absorption

Water, in the form of OH⁻ ions, creates a major absorption peak in the fiber's transmission window (around 1383 nm). The high-temperature, chlorine-rich environment of VPD is extremely effective at removing these water ions, resulting in "low water peak" fibers with low loss across the entire spectrum needed for modern wavelength division multiplexing (WDM).

Advantage 2: Precise Refractive Index Control

Optical fibers guide light using total internal reflection, which requires a core with a higher refractive index than the surrounding cladding. VPD provides complete control over this structure.

The Role of Dopants

By precisely metering the flow of dopant gases into the vapor stream, the refractive index of each deposited layer can be minutely controlled. For example, adding germanium tetrachloride (GeCl₄) increases the refractive index, while adding fluorine-based compounds can decrease it.

Designing the Waveguide Profile

This precise control allows for the creation of sophisticated refractive index profiles. A simple step-index profile is used for single-mode fiber, while a complex, parabolic graded-index (GRIN) profile is used in multi-mode fiber to minimize modal dispersion and maximize bandwidth.

Layer-by-Layer Flexibility

Because the deposition occurs in hundreds or thousands of gossamer-thin layers, engineers can create extremely smooth gradients and novel waveguide designs. This flexibility is essential for manufacturing different types of fiber, from the single-mode fibers that form the internet's backbone to specialty fibers used in lasers and sensors.

Understanding the Trade-offs

No technology is without its compromises. While VPD's advantages are immense, it's important to understand its challenges.

Process Complexity and Cost

VPD systems are sophisticated, requiring precise control over gas flow, temperature, and pressure. This makes the initial capital investment significantly higher than for simpler melt-based systems.

Handling of Hazardous Materials

The chemical precursors used, such as SiCl₄ and Cl₂, are corrosive and toxic. This necessitates robust safety protocols and infrastructure for handling and storage, adding to the operational complexity.

Slower Deposition Rates

VPD is an inherently slower, more deliberate process than bulk melting. The need to build the preform layer by layer can limit throughput, although modern techniques like Plasma Chemical Vapor Deposition (PCVD) have made significant strides in increasing deposition speed.

Making the Right Choice for Your Goal

The dominance of vapor phase deposition is a direct result of its ability to meet the stringent demands of modern optics.

- If your primary focus is long-haul telecommunications: VPD is the only viable choice, as its ability to produce single-mode fiber with ultra-low loss (<0.2 dB/km) is essential for transmitting signals across continents.

- If your primary focus is high-bandwidth data centers: VPD's precise control over graded-index profiles is critical for creating multi-mode fibers that minimize signal distortion and support massive data rates over several hundred meters.

- If your primary focus is specialty fibers for lasers or sensors: The design flexibility of VPD is paramount, allowing for the creation of complex and novel core/cladding structures tailored to specific photonic applications.

Ultimately, vapor phase deposition is the foundational technology that transforms simple raw chemicals into the flawless glass highways that form the physical backbone of our digital world.

Summary Table:

| Advantage | Key Benefit | Impact on Optical Fiber |

|---|---|---|

| Unprecedented Purity | Ultra-pure precursors (ppb level) via distillation | Drastically reduces signal loss from absorption (e.g., metal ions, OH⁻) |

| Precise Refractive Index Control | Layer-by-layer deposition with dopant gases (e.g., GeCl₄) | Enables complex waveguide profiles (step-index, graded-index) for minimal dispersion |

| Design Flexibility | Builds glass preform molecule by molecule | Allows creation of specialty fibers for lasers, sensors, and high-bandwidth applications |

Ready to elevate your laboratory's capabilities in materials science and photonics research? KINTEK specializes in providing high-precision lab equipment and consumables essential for advanced processes like vapor phase deposition. Whether you are developing next-generation optical fibers or other high-purity materials, our expertise supports your innovation. Contact our experts today to discuss how our solutions can meet your specific research and production needs.

Visual Guide

Related Products

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

People Also Ask

- How does PECVD work? Enable Low-Temperature, High-Quality Thin Film Deposition

- What are the methods of deposition? A Guide to PVD and CVD Thin-Film Techniques

- How are thin films deposited? A Guide to PVD vs. CVD Methods for Your Application

- What is the vapor phase deposition technique? A Guide to PVD & CVD Thin-Film Coating Methods

- What are the steps of the CVD process? A Guide to Precision Thin Film Deposition