The primary methods for hunting leaks in a vacuum system range from simple pressure-rise tests to highly sensitive gas analysis. Common techniques include injecting a solvent like acetone near a suspected leak and observing the vacuum gauge, systematically isolating sections of the system with blind plates, and for maximum precision, using a helium mass spectrometer leak detector.

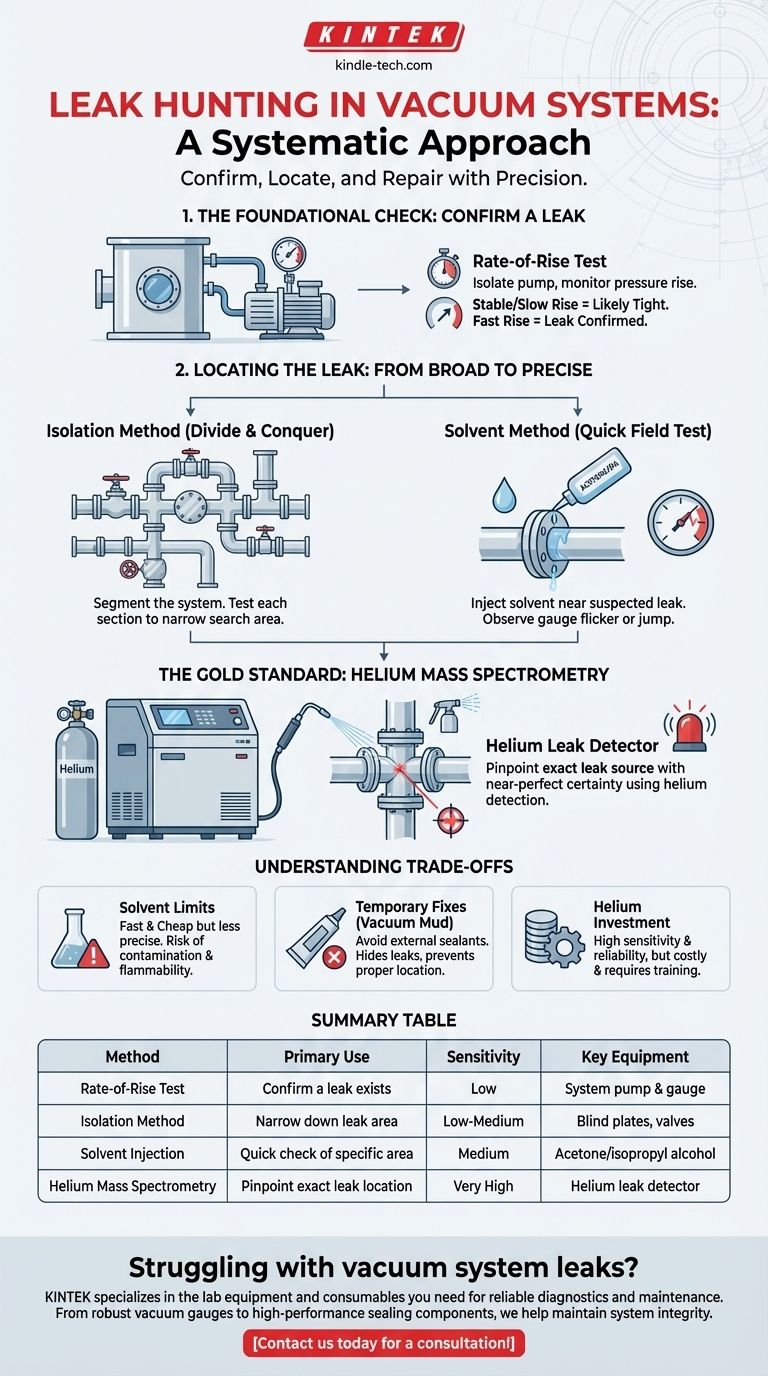

Effective leak hunting is a systematic process. It begins with confirming a leak exists, then logically narrows down its location using progressively more sensitive methods, moving from system-wide checks to pinpoint detection.

The Foundational Check: Confirming a Leak Exists

Before you begin searching for a specific leak point, you must first confirm that the system is not holding a vacuum. The simplest way to do this is with a rate-of-rise test.

Performing a Rate-of-Rise Test

A rate-of-rise test, also known as a pressure rise test, is your first diagnostic step. The procedure is straightforward and requires no special equipment beyond your system's pump and gauge.

First, evacuate the system to its normal operating pressure.

Next, close the valve that connects the vacuum chamber to the pump, isolating the chamber completely.

Finally, monitor the vacuum gauge. If the pressure remains stable or rises very slowly, your system is likely tight. If the pressure rises quickly, you have confirmed a leak and can proceed to localization methods.

Locating the Leak: From Broad to Precise

Once you've confirmed a leak, the goal is to find its exact location. The best strategy is to start with methods that narrow the search area before moving to more precise techniques.

The Isolation Method: Divide and Conquer

For complex systems with multiple tubes and components, the most logical first step is to isolate sections. This helps you determine which part of the system is compromised.

This is often done using blind plates or by closing specific valves to segment the vacuum plumbing. You can then perform a rate-of-rise test on each isolated section. The section that shows the fastest pressure rise contains the leak.

The Solvent Method: A Quick Field Test

Once you have a general idea of where the leak might be, such as a specific flange or weld, you can use the solvent injection method for a quick check.

Using a medical needle or fine-tipped squirt bottle, you apply a small amount of a volatile solvent like acetone or isopropyl alcohol to the suspected area.

When the solvent hits the leak, it is drawn into the vacuum system. The solvent's vapor temporarily changes the gas composition and pressure, causing a noticeable flicker or jump in the reading of your vacuum gauge.

The Gold Standard: Helium Mass Spectrometry

For the highest level of sensitivity and accuracy, the definitive tool is the helium mass spectrometer leak detector. This device is capable of detecting incredibly small leaks that other methods would miss.

The system is evacuated and connected to the spectrometer. The operator then sprays a fine stream of helium gas around suspected leak points on the outside of the system.

Helium atoms are very small and inert. If a leak is present, the helium is sucked into the vacuum, travels through the system, and is detected by the spectrometer, which sounds an alarm. This allows you to pinpoint the exact source of a leak with near-perfect certainty.

Understanding the Trade-offs and Pitfalls

Each leak detection method has its own set of advantages and disadvantages. Choosing the right one depends on your system, your budget, and the level of integrity required.

The Limits of Solvents

The solvent method is fast and inexpensive, but it is not precise. It can confirm a leak in a general area but struggles to pinpoint the exact spot. Furthermore, using solvents like acetone can introduce contaminants into a sensitive vacuum system and poses a flammability risk.

The Danger of "Temporary" Fixes

The references mention using vacuum mud or other external sealing compounds. These should only be considered temporary, emergency measures. Applying a sealant makes it impossible to locate the leak later and can hide a developing mechanical failure. The only true solution is to find the leak and repair it properly.

The Investment for Precision

A helium mass spectrometer is an expensive piece of equipment that requires a trained operator. While it is the most reliable method, its cost and complexity mean it is typically reserved for high-performance, high-vacuum systems where even minuscule leaks are unacceptable.

Making the Right Choice for Your Goal

To select the best approach, evaluate the needs of your system and the urgency of the problem.

- If your primary focus is quick confirmation: Start with a simple rate-of-rise test to determine if you even have a significant leak.

- If your primary focus is locating a leak in a complex system: Use the isolation method to divide the system and narrow down the search area efficiently.

- If your primary focus is a fast, low-cost check of a specific weld or joint: The solvent method can work well, provided you are aware of the contamination risks.

- If your primary focus is absolute certainty for a high-vacuum or critical system: The helium mass spectrometer is the only method that provides the necessary precision and reliability.

By approaching leak detection systematically, you can efficiently diagnose and restore your vacuum system's integrity.

Summary Table:

| Method | Primary Use | Sensitivity | Key Equipment |

|---|---|---|---|

| Rate-of-Rise Test | Confirm a leak exists | Low | System pump & gauge |

| Isolation Method | Narrow down leak area | Low-Medium | Blind plates, valves |

| Solvent Injection | Quick check of specific area | Medium | Acetone/isopropyl alcohol |

| Helium Mass Spectrometry | Pinpoint exact leak location | Very High | Helium leak detector |

Struggling with vacuum system leaks? KINTEK specializes in the lab equipment and consumables you need for reliable diagnostics and maintenance. From robust vacuum gauges to high-performance sealing components, our solutions help you maintain system integrity and achieve precise results. Let our experts help you select the right tools for your specific application. Contact us today for a consultation!

Visual Guide

Related Products

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- Benchtop Laboratory Vacuum Freeze Dryer

- Oil Free Diaphragm Vacuum Pump for Laboratory and Industrial Use

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

People Also Ask

- How do you sterilize glassware by autoclave? Master the 3-Step Process for Reliable Sterility

- What is the use of autoclave in medical? The Critical Role of Sterilization in Patient Safety

- Why is it important to autoclave the prepared reagents before using? Ensure Sterility and Reliable Results

- What are the sizes of autoclaves? A Guide to Choosing the Right Capacity for Your Lab

- Can autoclave sterilize liquid? Master Safe and Effective Liquid Sterilization