The primary parameters of RF sputtering are the power source frequency, operating pressure, power level, and the type of inert gas used. These factors work together to control the plasma environment and, consequently, the rate and quality of the thin film deposition.

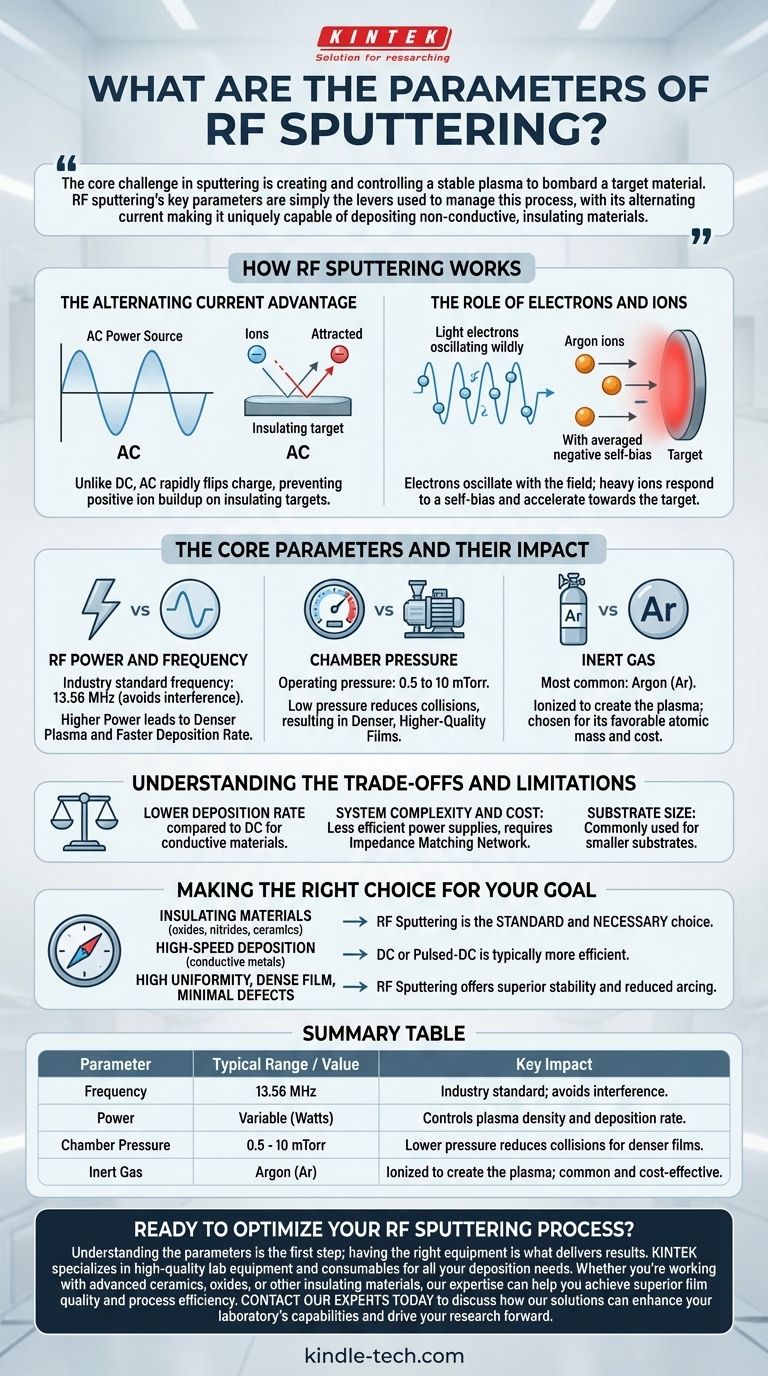

The core challenge in sputtering is creating and controlling a stable plasma to bombard a target material. RF sputtering's key parameters are simply the levers used to manage this process, with its alternating current making it uniquely capable of depositing non-conductive, insulating materials.

How RF Sputtering Works

The Alternating Current Advantage

Unlike DC sputtering, which uses a constant negative voltage, RF sputtering employs an Alternating Current (AC) power source. This rapidly flips the charge on the target material.

This oscillation is the key to sputtering insulating (dielectric) materials. A constant DC voltage would cause positive ion charges to build up on an insulating target, repelling further ions and quickly stopping the sputtering process.

The Role of Electrons and Ions

The AC field affects electrons and ions differently due to their vast difference in mass. The lightweight electrons are able to oscillate with the high-frequency field.

Heavier gas ions (like Argon) cannot keep up with the rapid switching. Instead, they respond to an averaged negative charge, or self-bias, that naturally forms on the target surface, accelerating them toward the target to cause sputtering.

The Core Parameters and Their Impact

RF Power and Frequency

The industry standard frequency is fixed at 13.56 MHz. This specific frequency is chosen to avoid interfering with radio and communication bands.

The RF power level, often measured in watts, directly controls the energy of the plasma. Higher power generally leads to a denser plasma, which increases the sputtering rate and film deposition speed.

Chamber Pressure

RF sputtering operates at a relatively low pressure, typically between 0.5 to 10 mTorr (millitorr).

This low pressure is advantageous because it reduces the chance of sputtered atoms colliding with gas atoms on their way to the substrate. This results in a more direct "line-of-sight" deposition and can lead to higher-quality, denser films.

Inert Gas

An inert gas, most commonly Argon (Ar), is introduced into the vacuum chamber. It is this gas that is ionized to create the plasma.

The choice of gas can affect the sputter yield, but Argon is typically selected for its favorable combination of atomic mass and cost.

Understanding the Trade-offs and Limitations

Lower Deposition Rate

A significant trade-off is that RF sputtering generally has a lower deposition rate compared to DC sputtering for conductive materials.

System Complexity and Cost

The equipment is more complex and expensive. RF power supplies are less efficient than their DC counterparts and require a sophisticated impedance matching network between the power supply and the chamber to deliver power effectively.

Substrate Size

Partly due to the complexity and cost of scaling the equipment, RF sputtering is most commonly used for depositing films on smaller substrates.

Making the Right Choice for Your Goal

- If your primary focus is depositing insulating materials (like oxides, nitrides, or ceramics): RF sputtering is the standard and necessary choice, as DC sputtering is not a viable option.

- If your primary focus is high-speed deposition of conductive metals: DC or Pulsed-DC magnetron sputtering is typically the more efficient and cost-effective solution.

- If your primary focus is achieving a highly uniform, dense film with minimal defects: The stability of the RF plasma at low pressures and its reduction of arcing make it a superior choice.

Understanding these parameters allows you to select the correct deposition technique and tune the process to achieve your desired film properties.

Summary Table:

| Parameter | Typical Range / Value | Key Impact |

|---|---|---|

| Frequency | 13.56 MHz | Industry standard; avoids interference. |

| Power | Variable (Watts) | Controls plasma density and deposition rate. |

| Chamber Pressure | 0.5 - 10 mTorr | Lower pressure reduces collisions for denser films. |

| Inert Gas | Argon (Ar) | Ionized to create the plasma; common and cost-effective. |

Ready to Optimize Your RF Sputtering Process?

Understanding the parameters is the first step; having the right equipment is what delivers results. KINTEK specializes in high-quality lab equipment and consumables for all your deposition needs. Whether you're working with advanced ceramics, oxides, or other insulating materials, our expertise can help you achieve superior film quality and process efficiency.

Contact our experts today to discuss how our solutions can enhance your laboratory's capabilities and drive your research forward.

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- 1200℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

- 1400℃ Controlled Atmosphere Furnace with Nitrogen and Inert Atmosphere

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

People Also Ask

- Why does PECVD commonly use RF power input? For Precise Low-Temperature Thin Film Deposition

- What is the plasma CVD process? Achieve Low-Temperature Thin Film Deposition

- What are the advantages of plasma enhanced CVD? Enable Low-Temperature, High-Quality Thin Film Deposition

- How are PECVD and CVD different? A Guide to Choosing the Right Thin-Film Deposition Process

- What is the difference between PECVD and sputter? Choose the Right Thin-Film Deposition Method