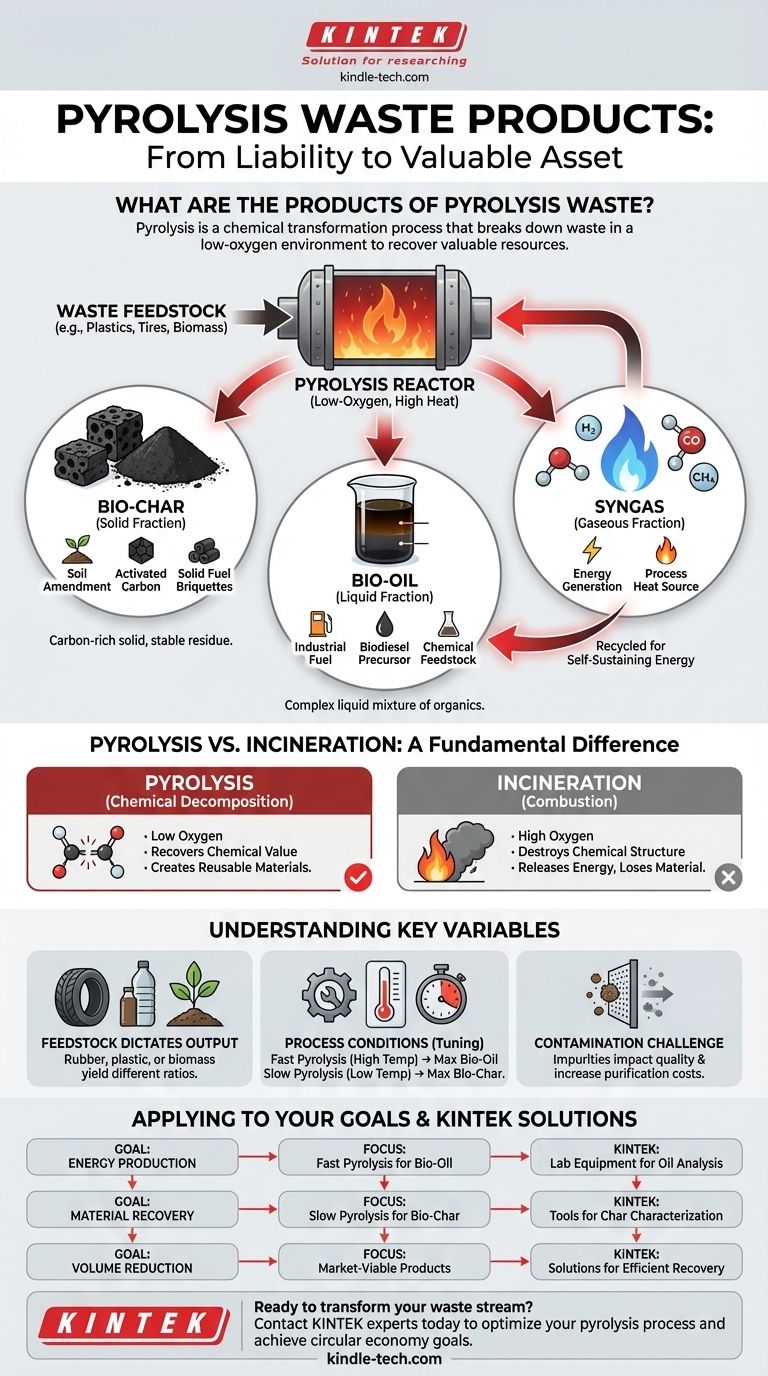

In short, the pyrolysis of waste yields three primary products: a solid known as bio-char, a liquid called bio-oil, and a combustible gas referred to as syngas. These outputs are not waste themselves but valuable resources that can be used for energy generation, agricultural applications, or as chemical feedstocks, turning a disposal problem into a material recovery opportunity.

Pyrolysis is fundamentally a process of chemical transformation, not simple disposal. It breaks down complex waste materials in a low-oxygen environment to recover their core chemical components as usable solid, liquid, and gaseous products.

The Three Core Products of Pyrolysis

Pyrolysis deconstructs organic materials like plastic, rubber, or biomass into simpler, more valuable substances. The exact ratio and composition of these products depend heavily on the type of waste being processed and the specific conditions of the pyrolysis reactor (e.g., temperature and speed).

The Solid Fraction: Bio-char (or Pyrolysis Coke)

Bio-char is the stable, carbon-rich solid that remains after the volatile components have been driven off. It is analogous to charcoal.

This material is highly versatile and can be used as a soil amendment to improve soil structure and water retention in agriculture, as a feedstock for producing activated carbon for filtration, or pressed into briquettes to be used as a solid fuel.

The Liquid Fraction: Bio-oil (or Pyrolysis Oil)

Bio-oil is a complex liquid mixture of water and organic compounds. It is sometimes separated into fractions like tar and wood vinegar, especially when processing biomass.

This dense, dark liquid can be used directly as an industrial fuel for boilers or furnaces. With further refining, it can be upgraded into higher-grade liquid fuels like biodiesel or serve as a source for valuable specialty chemicals.

The Gaseous Fraction: Syngas (or Pyrolysis Gas)

Syngas is a mix of non-condensable gases, primarily hydrogen, carbon monoxide, and methane. It is a combustible fuel gas.

A key benefit of the pyrolysis process is that this syngas is often recycled directly back into the plant. It is burned to provide the heat energy required to run the pyrolysis reactor, making the entire operation more energy-efficient and self-sustaining.

Why This Isn't Just Burning Waste

It is critical to distinguish pyrolysis from incineration. They are fundamentally different processes with different outcomes.

Pyrolysis as Chemical Decomposition

Pyrolysis uses heat in a near-absence of oxygen. This prevents combustion and instead causes a chemical breakdown of large molecules (like plastics) into smaller, more useful ones. It recovers the chemical value inherent in the waste.

Incineration as Combustion

Incineration uses large amounts of oxygen to completely burn waste. While this can be used to generate electricity from heat, it destroys the material's chemical structure, releasing its energy but losing its potential for reuse as a new material.

Understanding the Trade-offs and Variables

The output of a pyrolysis plant is not fixed. The process is a sophisticated balancing act where operators can influence the outcome based on their goals.

The Feedstock Dictates the Output

The type of waste used as feedstock is the single most important factor. Pyrolyzing rubber tires will produce a different ratio and quality of oil and char compared to pyrolyzing agricultural waste or mixed plastics.

Process Conditions Can Be Tuned

Operators can adjust the pyrolysis temperature and processing time to favor certain products. For example, "fast" pyrolysis at high temperatures maximizes the production of bio-oil, while "slow" pyrolysis at lower temperatures is designed to maximize the yield of bio-char.

The Challenge of Contamination

Real-world waste streams are rarely pure. Contaminants within the feedstock can impact the quality of the final products, potentially requiring costly purification steps before they can be sold or used, which is a critical economic consideration for any pyrolysis operation.

How to Apply This to Your Goal

The value of pyrolysis lies in matching the process to a specific objective. The desired end-product determines the ideal feedstock and operating conditions.

- If your primary focus is energy production: You should optimize for "fast" pyrolysis to maximize the yield of liquid bio-oil, which serves as a transportable and storable fuel.

- If your primary focus is material recovery or agriculture: You should utilize "slow" pyrolysis to generate the highest possible volume of high-quality bio-char for use in soil or for creating activated carbon.

- If your primary focus is waste volume reduction: Any pyrolysis setup will achieve this, but the economic viability depends on creating a market for the specific bio-char, bio-oil, and syngas your chosen feedstock produces.

Ultimately, pyrolysis offers a powerful tool to transform waste liabilities into valuable assets for a more circular economy.

Summary Table:

| Product | Description | Primary Uses |

|---|---|---|

| Bio-Char (Solid) | Carbon-rich solid residue | Soil amendment, activated carbon, solid fuel briquettes |

| Bio-Oil (Liquid) | Complex liquid mixture of water and organics | Industrial fuel, biodiesel precursor, chemical feedstock |

| Syngas (Gas) | Combustible gas mix (H2, CO, CH4) | Fuels the pyrolysis reactor, energy generation |

Ready to transform your waste stream into valuable resources? The right laboratory equipment is crucial for developing and optimizing your pyrolysis process. KINTEK specializes in the precise lab equipment and consumables needed for pyrolysis research and analysis. Whether you're characterizing feedstocks or testing product quality, our solutions help you achieve efficient and effective material recovery. Contact our experts today to discuss how we can support your pyrolysis project and contribute to your circular economy goals.

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

People Also Ask

- What are the conditions for biomass pyrolysis? Optimize Temperature, Heating Rate & Time

- Is pyrolysis viable? A Guide to Economic, Technological, and Environmental Success

- What is the process of biomass fast pyrolysis? Turn Biomass into Bio-Oil in Seconds

- What are the reactions involved in pyrolysis of biomass? Unlock the Chemistry for Tailored Bio-Products

- How is energy converted into biomass? Harnessing Nature's Solar Power for Renewable Energy