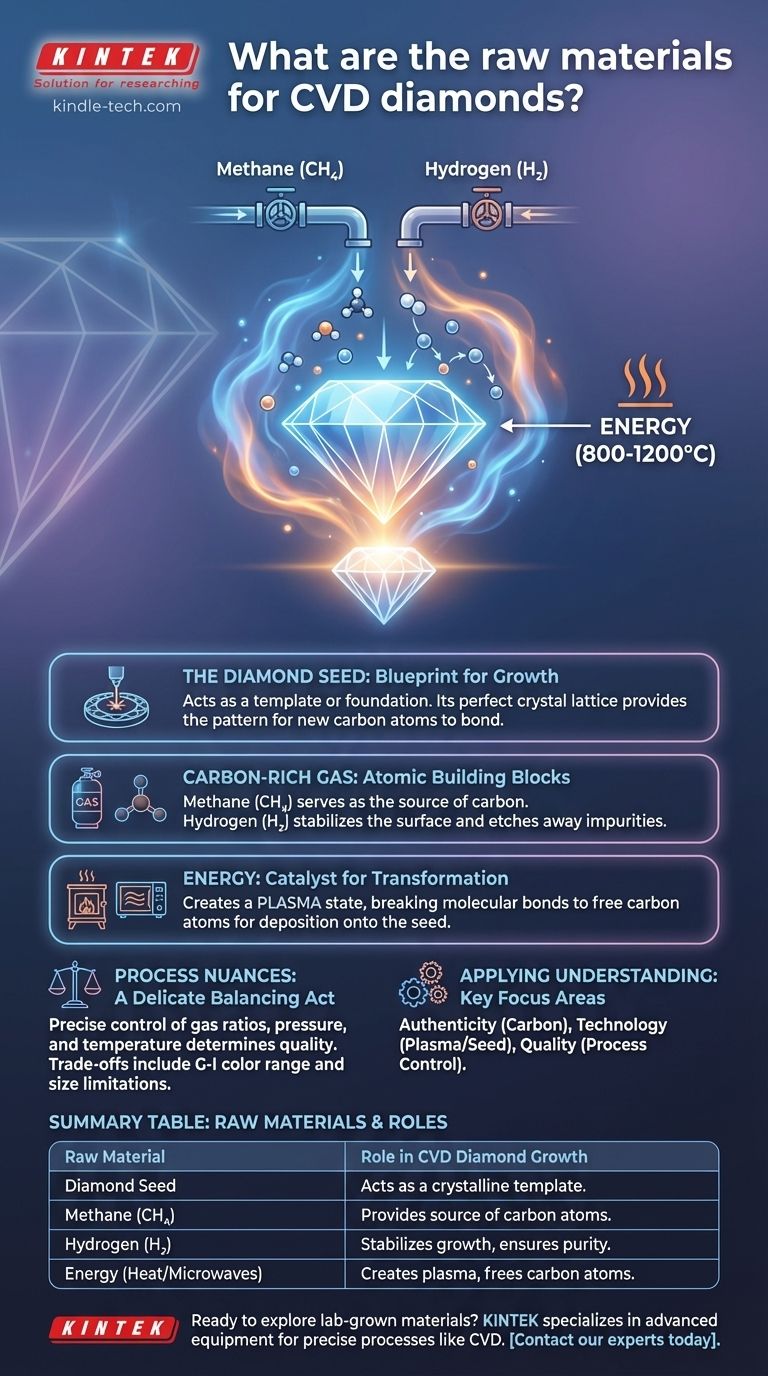

The primary raw materials required to create a CVD diamond are a diamond seed and a specific mixture of carbon-rich gases. The process uses a thin slice of a pre-existing diamond as a template and introduces gases like methane and hydrogen into a high-temperature, low-pressure chamber to provide the carbon atoms needed for growth.

The creation of a CVD diamond is not about assembling parts, but about cultivating a crystal. It requires two fundamental ingredients: a diamond seed to provide the atomic blueprint and a carbon-rich gas to supply the building blocks, which are then activated by intense heat.

The Role of Each Raw Material

To understand how a CVD diamond is formed, it's essential to understand the specific function of each component in the process. The materials themselves are simple, but their role in the highly controlled environment is critical.

The Diamond Seed: The Blueprint for Growth

The entire process begins with a diamond seed. This is a very thin, laser-cut slice of a pre-existing high-quality diamond, which can be either natural or a previously grown lab diamond.

This seed is not a raw ingredient in the traditional sense; it acts as a template or foundation. Its perfect crystal lattice structure provides the pattern upon which new carbon atoms will bond.

The Carbon-Rich Gas: The Atomic Building Blocks

The vacuum chamber containing the diamond seed is filled with a precise mixture of gases, typically methane (CH₄) and hydrogen (H₂).

Methane serves as the source of carbon. When subjected to intense energy, its molecular bonds break, releasing carbon atoms.

Hydrogen plays a crucial supporting role. It helps stabilize the diamond growth surface and selectively etches away any non-diamond carbon (like graphite) that might otherwise form, ensuring the purity of the final crystal.

Energy: The Catalyst for Transformation

The raw materials alone do nothing. The reaction is driven by immense energy, which transforms the gas into a reactive state known as plasma.

This is achieved by heating the chamber to extreme temperatures, typically between 800°C and 1200°C.

This heat, often assisted by microwaves, ionizes the gas mixture. In this plasma state, the methane molecules are broken apart, allowing the freed carbon atoms to "rain down" and deposit onto the diamond seed, growing the crystal layer by atomic layer.

Understanding the Trade-offs and Process Nuances

While the concept is straightforward, the execution is a delicate balancing act. The quality of the final diamond is entirely dependent on the precise control of the manufacturing process.

The Challenge of Purity and Control

The ratio of methane to hydrogen, the chamber pressure, and the exact temperature are all critical variables. Even minor fluctuations can impact the diamond's color, clarity, and structural integrity.

This is why different CVD manufacturing methods exist—each is an attempt to optimize these conditions for better quality and more efficient growth.

Typical Outcomes and Limitations

Historically, the CVD process has been known to produce diamonds with slightly warmer tones, often in the G-I color range. The process also faces challenges in growing very large, flawless crystals.

While technology is constantly improving, these characteristics are a direct trade-off of the process variables. Post-growth treatments are sometimes used to improve the color of the finished diamond.

How to Apply This to Your Understanding

Your reason for investigating these raw materials dictates which aspect of the process is most important.

- If your primary focus is on authenticity: The core ingredient is carbon, the same element that forms natural diamonds. The process simply uses technology to organize these carbon atoms in a controlled environment.

- If your primary focus is on the technology: The key is the transformation of simple methane gas into pure carbon via a plasma state, and the use of a diamond seed as a crystalline template.

- If your primary focus is on quality: The final quality of a CVD diamond is a direct result of how perfectly the process controls the gas mixture and energy input to ensure uniform crystal growth.

Ultimately, understanding these raw materials reveals that a CVD diamond is a testament to our ability to manipulate fundamental chemistry and cultivate one of nature's most valued structures.

Summary Table:

| Raw Material | Role in CVD Diamond Growth |

|---|---|

| Diamond Seed | Acts as a crystalline template for new carbon atoms to bond to. |

| Methane (CH₄) | Provides the source of carbon atoms for the diamond's structure. |

| Hydrogen (H₂) | Stabilizes growth and etches away non-diamond carbon, ensuring purity. |

| Energy (Heat/Microwaves) | Creates a plasma state, breaking down gases to free carbon atoms. |

Ready to explore the potential of lab-grown materials in your research or production? KINTEK specializes in providing the advanced lab equipment and consumables needed for precise processes like CVD. Whether you're developing new materials or scaling up production, our expertise can help you achieve superior results. Contact our experts today to discuss your specific laboratory needs!

Visual Guide

Related Products

- Cylindrical Resonator MPCVD Machine System Reactor for Microwave Plasma Chemical Vapor Deposition and Lab Diamond Growth

- CVD Diamond Cutting Tool Blanks for Precision Machining

- CVD Diamond Domes for Industrial and Scientific Applications

- Microwave Plasma Chemical Vapor Deposition MPCVD Machine System Reactor for Lab and Diamond Growth

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

People Also Ask

- What are the applications of CVD diamonds? From Jewelry to High-Tech Tools

- What is the use of CVD diamond? Unlock Superior Performance in Extreme Applications

- What is the growth rate of CVD diamond? Discover the Secret to High-Purity Lab-Grown Gems

- How are lab-grown diamonds created? Discover the HPHT and CVD Manufacturing Process

- What are the physical characteristics of synthetic diamonds? Identical to Natural Diamonds, Made in a Lab

- How can you tell the difference between a diamond and a CVD? The Expert's Guide to Identification

- How long do lab-grown diamonds take to make? A 6-8 Week Journey from Seed to Gem

- Are lab-grown diamonds comparable to natural diamonds? Discover the Science Behind the Sparkle