The primary risks of using an autoclave are physical hazards stemming from the extreme heat, steam, and high pressure required for sterilization. Temperatures exceed 250°F (121°C) and pressure is typically above 20 psi, creating significant potential for severe burns or explosive release of steam if operated incorrectly. Secondary risks include exposure to infectious biological materials or injury from sharp instruments being sterilized.

An autoclave's power is in its simplicity, using basic physical forces—heat, steam, and pressure—to achieve sterilization. Consequently, the greatest risks are not from complex technical failures, but from underestimating these raw forces and deviating from rigid, well-defined safety procedures.

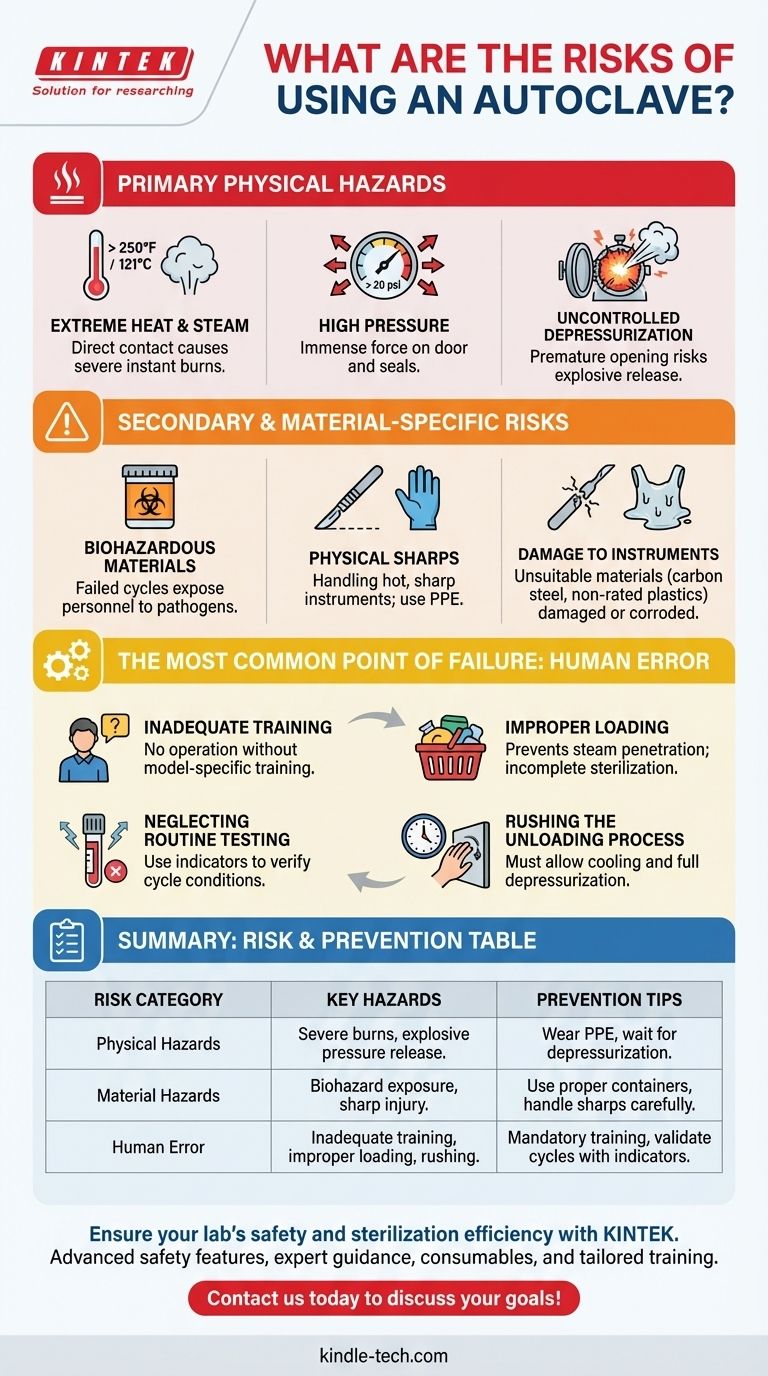

The Primary Physical Hazards

The most immediate dangers of an autoclave are rooted in the physics of its operation. It is a pressure vessel designed to contain a highly energetic and hazardous environment.

Extreme Heat and Steam

An autoclave uses steam heated to over 250°F (121°C) to sterilize its contents. Direct contact with this steam or with recently sterilized items will cause severe thermal burns instantly.

High Pressure

To achieve the necessary temperatures, the chamber is pressurized to at least 20 pounds per square inch (psi) above atmospheric pressure. This internal pressure places immense force on the door and seals.

Uncontrolled Depressurization

The most catastrophic risk is the premature opening of the autoclave door before the pressure has returned to a safe level. This can result in an explosive release of superheated steam and boiling water, causing severe injury to anyone nearby.

Secondary and Material-Specific Risks

Beyond the immediate physical dangers, operators must manage risks related to the materials being sterilized and the integrity of the process itself.

Biohazardous Materials

If a cycle fails or a container with infectious agents breaks or leaks, the contents may not be sterilized. This creates a risk of exposing personnel to active pathogens during unloading.

Physical Sharps

Handling sharp instruments is always a risk, but it's amplified when they are extremely hot after a cycle. Proper personal protective equipment (PPE) is essential to prevent both burns and puncture wounds.

Damage to Instruments and Materials

Autoclaves are not suitable for all materials. The moist heat can cause damage and corrosion to carbon steel instruments and will melt or deform any plastics that are not rated for high temperatures. This is a risk to your equipment, not just your personnel.

The Most Common Point of Failure: Human Error

The vast majority of autoclave incidents are not caused by equipment malfunction but by a failure to follow established safety protocols. Consistent, mandatory training is the single most important safety control.

Inadequate Training

No individual should operate an autoclave without being formally trained on that specific model. Training must cover the full cycle, safety features, proper loading and unloading, and emergency procedures.

Improper Loading

Overloading the chamber or using sealed containers can prevent steam from penetrating the load, leading to an incomplete sterilization cycle. This creates a significant biological risk.

Neglecting Routine Testing

Sterilization is not guaranteed just because a cycle runs. Using biological or chemical indicators is critical to verify that the autoclave is reaching the necessary conditions to kill microorganisms. A cycle that fails without being noticed can lead to the use of non-sterile instruments.

Rushing the Unloading Process

Patience is a critical safety tool. After the cycle completes, the chamber must be allowed to cool and depressurize completely before the door is unlatched. Rushing this step is a primary cause of steam-related injuries.

Making the Right Choice for Your Goal

Your operational focus dictates which safety protocols are most critical.

- If your primary focus is personnel safety: Prioritize mandatory, model-specific training on loading, unloading, and emergency procedures, with a strict policy on wearing heat-resistant gloves, eye protection, and closed-toe shoes.

- If your primary focus is sterilization efficacy: Implement a rigid protocol for proper loading techniques and the mandatory use of chemical and biological indicators to validate every cycle.

- If your primary focus is equipment longevity: Enforce strict rules on only sterilizing approved materials, such as stainless steel and autoclavable plastics, to prevent damage to both the instruments and the machine itself.

Ultimately, mastering the autoclave is about disciplined adherence to procedure, transforming a potential hazard into an indispensable and reliable tool.

Summary Table:

| Risk Category | Key Hazards | Prevention Tips |

|---|---|---|

| Physical Hazards | Severe burns from steam/hot surfaces, explosive pressure release | Always wear PPE, wait for full depressurization before opening |

| Material Hazards | Exposure to biohazards, injury from sharp instruments | Use proper containers, handle sharps carefully post-cycle |

| Human Error | Inadequate training, improper loading, rushing unloading | Mandatory model-specific training, validate cycles with indicators |

Ensure your lab's safety and sterilization efficiency with KINTEK. Our autoclaves are designed with advanced safety features to minimize risks, and our team provides expert guidance on proper usage and maintenance. Whether you need reliable equipment, consumables like biological indicators, or tailored training for your staff, KINTEK is your trusted partner for all laboratory sterilization needs. Contact us today to discuss how we can support your lab's safety and performance goals!

Visual Guide

Related Products

- Portable Digital Display Automatic Laboratory Sterilizer Lab Autoclave for Sterilization Pressure

- Desktop Fast Laboratory Autoclave Sterilizer 20L 24L for Lab Use

- Portable High Pressure Laboratory Autoclave Steam Sterilizer for Lab Use

- Desktop Fast Laboratory Autoclave Sterilizer 35L 50L 90L for Lab Use

- Laboratory High Pressure Steam Sterilizer Vertical Autoclave for Lab Department

People Also Ask

- What are the advantages of Molybdenum for autoclave construction? Superior Purity & Chemical Stability in Nitride Synthesis

- What is the use of autoclave in medical? The Critical Role of Sterilization in Patient Safety

- What are the 5 types of autoclave? The 3 Key Classes That Define Sterilization Safety

- What are the do's and don'ts in using autoclave? A Guide to Safe and Effective Sterilization

- What instruments are sterilized in an autoclave the temperature must be maintained at what? The Essential Guide to Effective Sterilization

- How is an autoclave utilized in antimicrobial experiments? Ensure Precise Nanoparticle Research Integrity

- What does autoclaving do to bacteria? It Destroys Them with High-Temperature Steam and Pressure

- Are autoclaves safe? How to Ensure Sterilization Safety in Your Lab